Engineered cork offers enhanced durability and uniformity compared to natural cork, making it ideal for flooring and insulation applications where consistency is key. Natural cork provides superior eco-friendliness and breathability, often preferred for sustainable products and acoustic insulation due to its natural cellular structure. Both materials excel in thermal insulation and resilience, but engineered cork's manufactured precision allows for tailored performance in modern architectural uses.

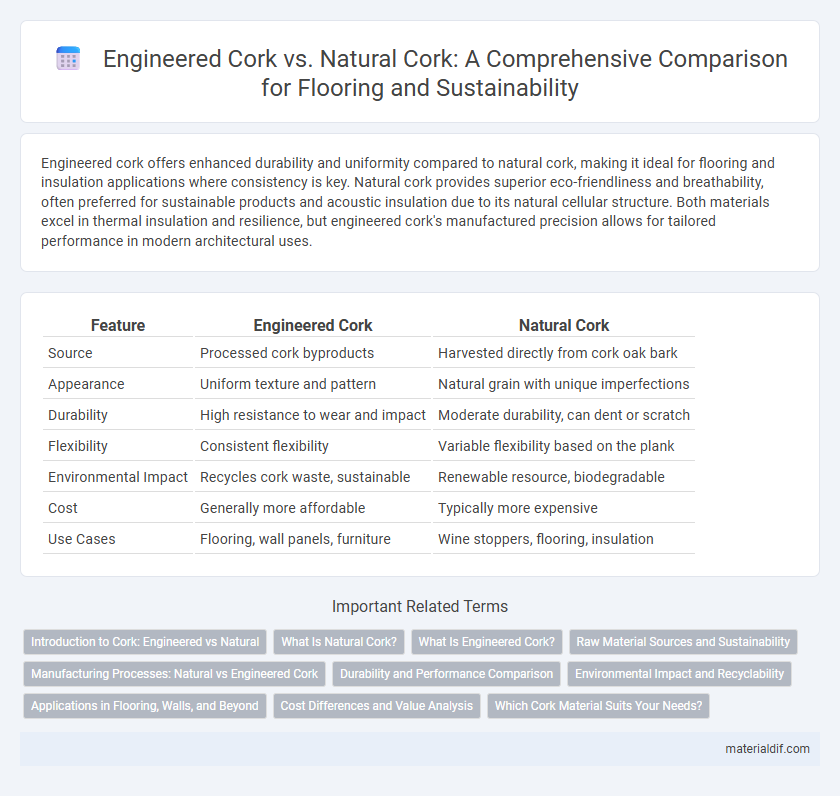

Table of Comparison

| Feature | Engineered Cork | Natural Cork |

|---|---|---|

| Source | Processed cork byproducts | Harvested directly from cork oak bark |

| Appearance | Uniform texture and pattern | Natural grain with unique imperfections |

| Durability | High resistance to wear and impact | Moderate durability, can dent or scratch |

| Flexibility | Consistent flexibility | Variable flexibility based on the plank |

| Environmental Impact | Recycles cork waste, sustainable | Renewable resource, biodegradable |

| Cost | Generally more affordable | Typically more expensive |

| Use Cases | Flooring, wall panels, furniture | Wine stoppers, flooring, insulation |

Introduction to Cork: Engineered vs Natural

Engineered cork combines natural cork granules with resins or binders to create a versatile, uniform material ideal for flooring and insulation. Natural cork is harvested directly from the cork oak tree's bark, prized for its sustainable, renewable qualities and unique cellular structure. Both types offer exceptional durability and moisture resistance, but engineered cork provides enhanced consistency and customizable properties for diverse applications.

What Is Natural Cork?

Natural cork is harvested directly from the bark of cork oak trees, primarily found in Mediterranean regions such as Portugal and Spain, without undergoing extensive processing. This sustainable material retains its cellular structure, offering exceptional elasticity, impermeability, and durability, making it ideal for wine stoppers, flooring, and insulation. Unlike engineered cork, which combines cork granules with adhesives, natural cork maintains its purity and eco-friendly properties through careful, manual extraction methods.

What Is Engineered Cork?

Engineered cork is a composite material made by binding natural cork granules with a resin or binder, creating panels or tiles that offer enhanced durability, uniformity, and moisture resistance compared to natural cork. This innovation allows for precise control over thickness, density, and surface texture, making engineered cork ideal for flooring, wall coverings, and insulation applications in both residential and commercial settings. Unlike natural cork harvested directly from cork oak bark, engineered cork maximizes resource efficiency by utilizing cork byproducts, promoting sustainability and reducing environmental impact.

Raw Material Sources and Sustainability

Engineered cork is produced by combining natural cork granules sourced from the bark of Quercus suber trees with binders, utilizing leftover cork from industrial processes, which enhances material efficiency and reduces waste. Natural cork, harvested directly from cork oak trees without processing, requires careful management to prevent overharvesting and ensure the tree's regeneration every 9 to 12 years. Sustainability in engineered cork benefits from its use of recycled cork pieces and reduced reliance on fresh bark, whereas natural cork's sustainability hinges on responsible forest management practices promoting biodiversity and carbon sequestration in cork oak landscapes.

Manufacturing Processes: Natural vs Engineered Cork

Natural cork is harvested from the bark of cork oak trees through a manual stripping process requiring careful timing to avoid damaging the tree and ensure sustainable regeneration every 9-12 years. Engineered cork is produced by grinding leftover cork pieces into granules, then binding them with adhesives under heat and pressure to create uniform sheets or blocks suitable for diverse applications. Manufacturing natural cork emphasizes preservation and minimal processing, while engineered cork prioritizes resource efficiency and material consistency through industrial assembly techniques.

Durability and Performance Comparison

Engineered cork offers enhanced durability compared to natural cork due to its compressed composition, making it more resistant to wear, moisture, and temperature fluctuations. Natural cork, while highly renewable and flexible, tends to be softer and less resilient under heavy foot traffic or prolonged exposure to humidity. Performance-wise, engineered cork provides superior dimensional stability and consistent quality, making it ideal for high-traffic areas and commercial applications.

Environmental Impact and Recyclability

Engineered cork, produced by agglomerating cork granules with resin binders, often incorporates recycled materials, reducing waste and optimizing resource use compared to natural cork, which is harvested directly from cork oak bark without harming the tree. Both types are biodegradable and recyclable; however, engineered cork's resin content can complicate recycling processes, whereas natural cork's pure composition allows for easier reuse in eco-friendly products. The environmental impact of engineered cork is influenced by the energy-intensive manufacturing and potential emissions from binders, whereas natural cork supports biodiversity and carbon sequestration by preserving cork oak forests.

Applications in Flooring, Walls, and Beyond

Engineered cork offers enhanced durability and moisture resistance compared to natural cork, making it ideal for high-traffic flooring and wall applications in residential and commercial spaces. Natural cork retains superior breathability and eco-friendliness, preferred for acoustic panels and decorative wall coverings that emphasize sustainability. Both materials extend beyond flooring and walls into furniture design and insulation, leveraging cork's thermal and sound-absorbing properties.

Cost Differences and Value Analysis

Engineered cork typically costs less than natural cork due to its production process, which uses agglomerated cork granules bound with resins, allowing for efficient waste utilization and scalability. While natural cork offers superior elasticity and longevity, engineered cork provides a cost-effective alternative with consistent quality and versatile applications. Value analysis reveals that engineered cork balances affordability with durability, making it a preferred choice in budget-sensitive projects without significantly compromising performance.

Which Cork Material Suits Your Needs?

Engineered cork offers consistent quality, enhanced durability, and improved resistance to moisture, making it ideal for flooring and insulation applications where uniformity and longevity are critical. Natural cork provides a sustainable, biodegradable option with unique aesthetic variations and superior breathability, perfect for eco-conscious consumers seeking authentic textures and natural insulation properties. Assessing your specific requirements for durability, environmental impact, and design will help determine whether engineered or natural cork best suits your project.

Engineered Cork vs Natural Cork Infographic

materialdif.com

materialdif.com