Harvesting cork oak bark involves carefully stripping the outer bark without damaging the tree, allowing it to regenerate over time, which ensures a sustainable supply of natural cork. Cork agglomerate production uses granulated cork particles, often from lower-quality or recycled bark, fused together with binders to create versatile materials for insulation, flooring, and other applications. While cork oak bark harvesting preserves the ecological balance and yields premium cork products, cork agglomerate offers a cost-effective alternative with diverse industrial uses.

Table of Comparison

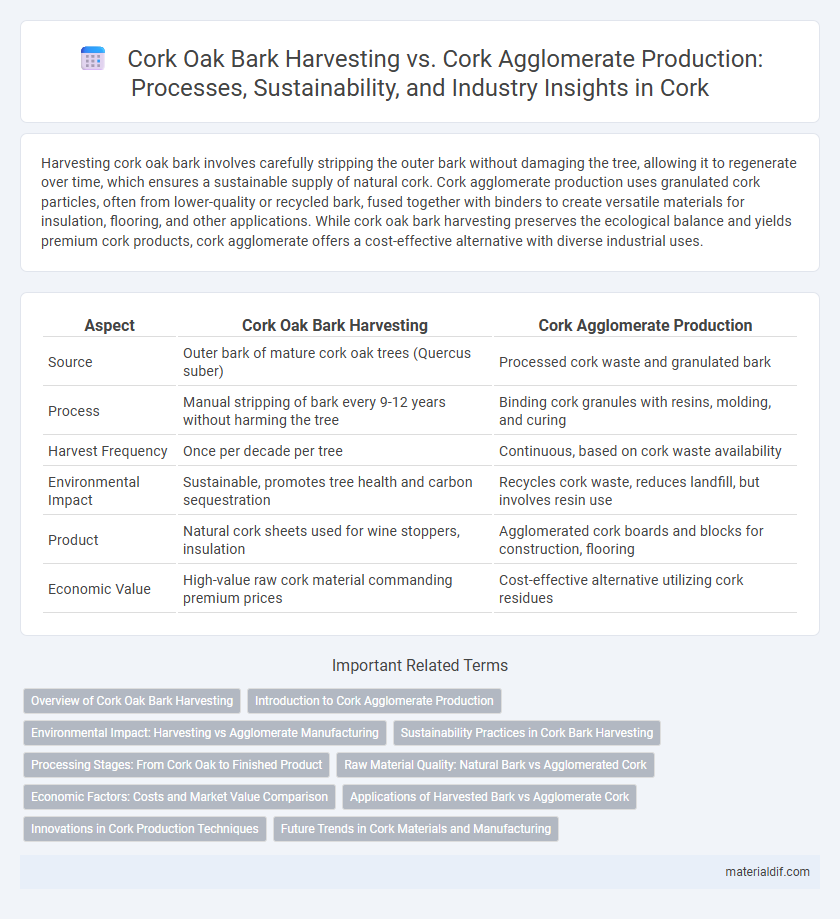

| Aspect | Cork Oak Bark Harvesting | Cork Agglomerate Production |

|---|---|---|

| Source | Outer bark of mature cork oak trees (Quercus suber) | Processed cork waste and granulated bark |

| Process | Manual stripping of bark every 9-12 years without harming the tree | Binding cork granules with resins, molding, and curing |

| Harvest Frequency | Once per decade per tree | Continuous, based on cork waste availability |

| Environmental Impact | Sustainable, promotes tree health and carbon sequestration | Recycles cork waste, reduces landfill, but involves resin use |

| Product | Natural cork sheets used for wine stoppers, insulation | Agglomerated cork boards and blocks for construction, flooring |

| Economic Value | High-value raw cork material commanding premium prices | Cost-effective alternative utilizing cork residues |

Overview of Cork Oak Bark Harvesting

Cork oak bark harvesting involves carefully stripping the outer bark from Quercus suber trees every 9 to 12 years without damaging the inner layer, allowing the tree to regenerate bark naturally. This sustainable process produces high-quality raw cork used primarily for bottle stoppers, while cork agglomerate production utilizes lower-grade cork remnants bonded with adhesives to create composite materials for insulation and flooring. Proper cork oak bark harvesting not only sustains the cork oak forests in the Mediterranean region but also supports biodiversity and local economies dependent on traditional cork industries.

Introduction to Cork Agglomerate Production

Cork agglomerate production utilizes cork oak bark remnants that do not meet quality standards for natural cork stoppers, transforming them into versatile materials through granulation and binding processes. This method maximizes resource efficiency by recycling lower-grade cork from the traditional harvesting cycles typically occurring every 9 to 12 years. Agglomerated cork is widely applied in flooring, insulation, and industrial uses, offering sustainable alternatives derived directly from cork oak forests.

Environmental Impact: Harvesting vs Agglomerate Manufacturing

Cork oak bark harvesting is a sustainable process that promotes forest conservation and biodiversity by allowing trees to regenerate their bark every 9-12 years, reducing carbon emissions and preventing deforestation. In contrast, cork agglomerate production involves energy-intensive processes, including grinding and gluing cork granules, which contribute to higher carbon footprints and chemical use. The environmental impact of harvesting is considerably lower than manufacturing agglomerates, positioning it as an eco-friendly practice crucial for maintaining Portugal and Spain's cork oak ecosystems.

Sustainability Practices in Cork Bark Harvesting

Cork oak bark harvesting follows sustainable practices by allowing trees to regenerate every 9 to 12 years without cutting them down, preserving biodiversity and preventing deforestation. This method maintains the cork oak forests' carbon sequestration capabilities, contributing significantly to climate change mitigation. In contrast, cork agglomerate production utilizes cork granules bonded with adhesives, often incorporating recycled cork, which supports waste reduction but depends heavily on the initial sustainable harvesting of raw cork bark.

Processing Stages: From Cork Oak to Finished Product

Cork oak bark harvesting involves carefully stripping the outer layer of the cork oak tree every 9 to 12 years without damaging the tree, ensuring sustainable raw material for production. Following the harvest, the bark undergoes boiling and drying to clean and stabilize the cork sheets before being sorted by quality. In cork agglomerate production, these sorted cork pieces are ground, mixed with adhesives, and then molded under heat and pressure to create versatile finished products like flooring, insulation panels, and tiles.

Raw Material Quality: Natural Bark vs Agglomerated Cork

Natural cork oak bark harvested directly from mature trees offers superior raw material quality due to its cellular structure, elasticity, and purity, essential for premium applications like wine stoppers and insulation panels. Agglomerated cork, made from ground cork granules bonded with adhesives, compromises some of these intrinsic properties, resulting in a denser, less flexible material suitable for industrial uses where uniformity and cost-efficiency outweigh natural performance benefits. The choice between natural bark and agglomerated cork hinges on the desired balance between raw material authenticity, mechanical properties, and economic considerations in cork product manufacturing.

Economic Factors: Costs and Market Value Comparison

Cork oak bark harvesting involves low operational costs but requires a long growth cycle of 9 to 12 years between harvests, impacting cash flow for producers. Cork agglomerate production demands higher upfront investment in processing technology and energy, yet it allows for value-added products with broader market applications, often achieving higher market prices. Market demand for premium natural cork products supports better profitability in traditional bark harvesting, while cork agglomerates cater to industrial uses, balancing cost efficiency with diversified revenue streams.

Applications of Harvested Bark vs Agglomerate Cork

Harvested cork oak bark is primarily used for natural cork products like wine stoppers, insulation, and flooring due to its elasticity, breathability, and sustainability. Cork agglomerate, produced by binding cork granules with adhesives, is widely applied in industrial insulation, soundproofing panels, and decorative tiles, leveraging its cost-effectiveness and uniform density. The choice between harvested bark and agglomerate cork depends on application-specific requirements such as durability, appearance, and environmental impact.

Innovations in Cork Production Techniques

Innovations in cork production techniques have enhanced both cork oak bark harvesting and cork agglomerate manufacturing by improving efficiency and sustainability. Advanced mechanized tools allow for more precise harvesting of cork oak bark, minimizing tree damage and promoting faster regeneration cycles. Meanwhile, state-of-the-art agglomeration technologies utilize recycled cork granules bonded with eco-friendly resins, resulting in high-quality, durable cork agglomerate products used in construction and design industries.

Future Trends in Cork Materials and Manufacturing

Cork oak bark harvesting remains a sustainable practice essential for high-quality cork production, while cork agglomerate manufacturing leverages reclaimed cork waste to create versatile, eco-friendly materials suited for construction and design. Innovations in automated harvesting techniques and advanced binding agents for agglomerates are driving efficiency and expanding application possibilities. Future trends emphasize circular economy principles, enhancing cork materials' durability and environmental benefits across industries.

cork oak bark harvesting vs cork agglomerate production Infographic

materialdif.com

materialdif.com