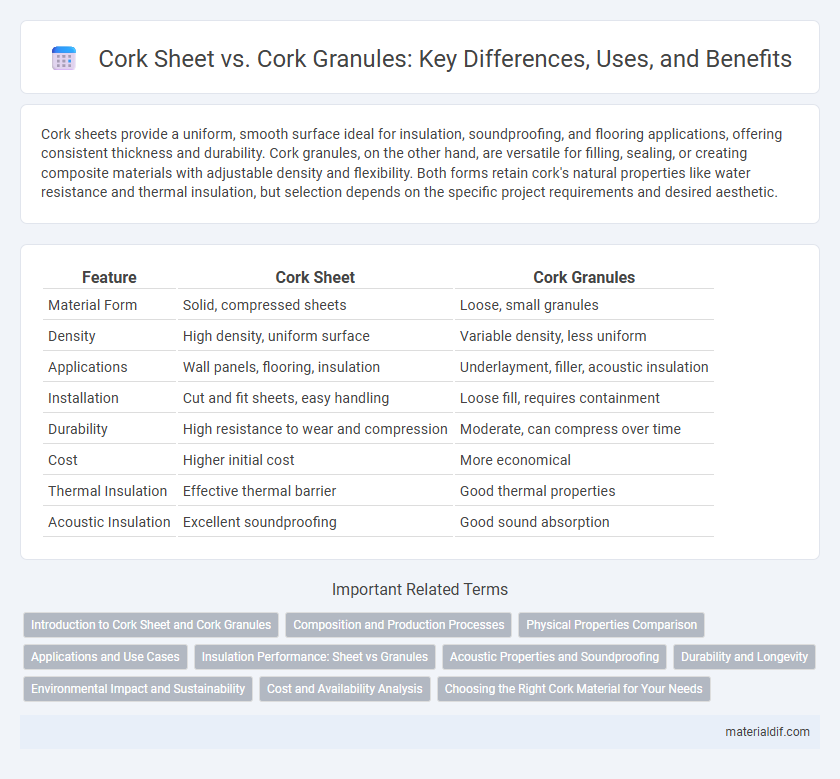

Cork sheets provide a uniform, smooth surface ideal for insulation, soundproofing, and flooring applications, offering consistent thickness and durability. Cork granules, on the other hand, are versatile for filling, sealing, or creating composite materials with adjustable density and flexibility. Both forms retain cork's natural properties like water resistance and thermal insulation, but selection depends on the specific project requirements and desired aesthetic.

Table of Comparison

| Feature | Cork Sheet | Cork Granules |

|---|---|---|

| Material Form | Solid, compressed sheets | Loose, small granules |

| Density | High density, uniform surface | Variable density, less uniform |

| Applications | Wall panels, flooring, insulation | Underlayment, filler, acoustic insulation |

| Installation | Cut and fit sheets, easy handling | Loose fill, requires containment |

| Durability | High resistance to wear and compression | Moderate, can compress over time |

| Cost | Higher initial cost | More economical |

| Thermal Insulation | Effective thermal barrier | Good thermal properties |

| Acoustic Insulation | Excellent soundproofing | Good sound absorption |

Introduction to Cork Sheet and Cork Granules

Cork sheets are thin, flexible panels made from compressed cork bark, commonly used for insulation, flooring, and craft projects due to their durability and natural water resistance. Cork granules consist of small, irregularly shaped particles derived from ground cork bark, often utilized in composite materials, thermal insulation, and soil conditioning for improved aeration. Both forms leverage cork's lightweight, renewable nature and thermal properties but differ in texture and application versatility.

Composition and Production Processes

Cork sheets are made by carefully slicing natural cork bark into thin, uniform layers, preserving the cellular structure that provides elasticity and durability. Cork granules result from grinding leftover cork pieces into small particles, which are then bonded using resins or natural binders to form composite materials. The production of cork sheets emphasizes precision and minimal alteration of raw cork, while cork granules involve mechanical processing and binding to create versatile, engineered products.

Physical Properties Comparison

Cork sheets exhibit uniform density, smooth surface texture, and higher tensile strength compared to cork granules, which are irregular in shape and vary in density. Cork granules offer superior compressibility and flexibility, making them ideal for insulation and cushioning applications, whereas cork sheets provide better structural stability and durability for flooring and wall panels. Thermal conductivity values are generally lower in cork granules due to increased air gaps, enhancing their insulating properties relative to the denser cork sheets.

Applications and Use Cases

Cork sheets are widely used for flooring, wall coverings, and soundproofing due to their uniform thickness, durability, and ease of installation. Cork granules excel in applications such as insulation, composite materials, and as a filler in sports flooring, providing excellent thermal and acoustic properties with flexibility in shaping. Both forms of cork contribute to sustainable construction, but sheets are preferred for structural applications while granules suit versatile, molded, or blended products.

Insulation Performance: Sheet vs Granules

Cork sheets offer superior insulation performance due to their uniform density and consistent thickness, providing excellent thermal resistance and minimizing heat transfer. Cork granules, while flexible and ideal for filling irregular spaces, have lower insulation efficiency because of air gaps between particles that reduce overall thermal conductivity. For applications demanding high and reliable thermal insulation, cork sheets are the preferred choice over granules.

Acoustic Properties and Soundproofing

Cork sheets offer superior acoustic insulation due to their dense, uniform structure that effectively absorbs sound waves and reduces noise transmission, making them ideal for soundproofing walls and floors. Cork granules, while providing decent sound absorption when used in composites or underlayments, have a looser, less consistent form that limits their effectiveness in blocking airborne noise. For optimal soundproofing in construction and interior applications, cork sheets are preferred for their enhanced noise reduction and vibration dampening properties.

Durability and Longevity

Cork sheets offer superior durability compared to cork granules due to their uniform structure and compressed density, making them ideal for heavy-use applications such as flooring and wall panels. Cork granules are less dense and more prone to wear and crumbling over time, which reduces their longevity in high-traffic or load-bearing environments. When selecting materials for long-lasting cork products, cork sheets provide enhanced resistance to abrasion, moisture, and impact, ensuring extended service life.

Environmental Impact and Sustainability

Cork sheets offer higher durability and reusability compared to cork granules, resulting in less frequent replacement and reduced environmental waste. Cork granules, often used as insulation, provide excellent thermal properties and are biodegradable, but their processing can generate more energy consumption. Both materials are harvested from the cork oak tree, a renewable resource that supports biodiversity and carbon sequestration, making them sustainable options in eco-friendly construction and design.

Cost and Availability Analysis

Cork sheets generally have higher production costs due to the labor-intensive harvesting and processing methods compared to cork granules, which are a byproduct of cork processing and typically more cost-effective. Availability of cork sheets can be limited and seasonal, as they rely on whole cork bark harvesting, whereas cork granules are more readily available year-round as they are produced from leftover cork materials. In terms of pricing, cork granules often provide a budget-friendly option for insulation and flooring applications, while cork sheets are preferred for premium, uniform finishes despite a higher price point.

Choosing the Right Cork Material for Your Needs

Cork sheet offers a uniform, dense structure ideal for insulation, sealing, and craft projects requiring precise cuts and durability, while cork granules provide flexibility and excellent shock absorption, making them suitable for filler materials, underlayment, and molding applications. Consider factors like thermal insulation, compressibility, and installation methods to determine the best cork form for your project's functional and aesthetic needs. Selecting between cork sheet and cork granules depends on the specific performance requirements and the intended use environment.

Cork Sheet vs Cork Granules Infographic

materialdif.com

materialdif.com