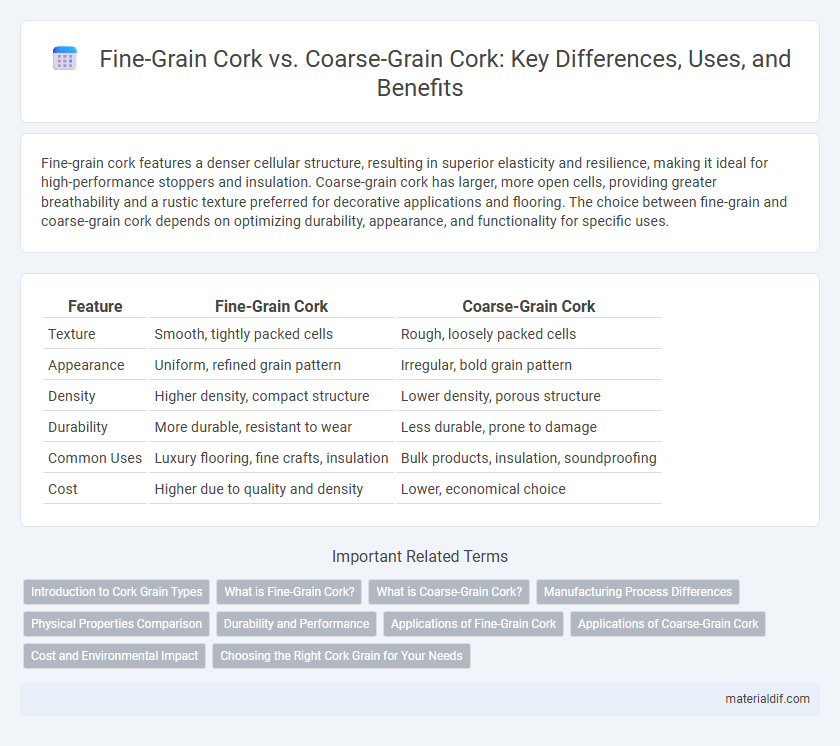

Fine-grain cork features a denser cellular structure, resulting in superior elasticity and resilience, making it ideal for high-performance stoppers and insulation. Coarse-grain cork has larger, more open cells, providing greater breathability and a rustic texture preferred for decorative applications and flooring. The choice between fine-grain and coarse-grain cork depends on optimizing durability, appearance, and functionality for specific uses.

Table of Comparison

| Feature | Fine-Grain Cork | Coarse-Grain Cork |

|---|---|---|

| Texture | Smooth, tightly packed cells | Rough, loosely packed cells |

| Appearance | Uniform, refined grain pattern | Irregular, bold grain pattern |

| Density | Higher density, compact structure | Lower density, porous structure |

| Durability | More durable, resistant to wear | Less durable, prone to damage |

| Common Uses | Luxury flooring, fine crafts, insulation | Bulk products, insulation, soundproofing |

| Cost | Higher due to quality and density | Lower, economical choice |

Introduction to Cork Grain Types

Fine-grain cork features smaller, tightly packed cells, providing greater flexibility and durability ideal for wine stoppers and high-end insulation. Coarse-grain cork has larger, more irregular cells, offering increased breathability and cushioning, commonly used for flooring and bulletin boards. Understanding these grain types helps optimize cork applications based on mechanical properties and aesthetic preferences.

What is Fine-Grain Cork?

Fine-grain cork is characterized by its dense and uniform cellular structure, making it more flexible and durable compared to coarse-grain cork. It is often sourced from the lower part of the cork oak bark, providing superior insulation and moisture resistance. This type of cork is highly valued for premium applications such as high-quality flooring, wine stoppers, and acoustic panels due to its refined texture and enhanced performance.

What is Coarse-Grain Cork?

Coarse-grain cork refers to cork material characterized by larger, more irregular cells compared to fine-grain cork, resulting in a rougher texture and less uniform appearance. It is commonly sourced from older cork oak trees, providing increased durability and resilience, making it suitable for industrial applications and insulation purposes. The larger grain structure also influences its compressibility and water resistance, distinguishing it from the softer, more flexible fine-grain cork often used in premium products.

Manufacturing Process Differences

Fine-grain cork is produced by carefully selecting and harvesting older cork oak trees with slower growth rates, resulting in tighter cellular structure, while coarse-grain cork originates from faster-growing trees with larger cellular patterns. The manufacturing process for fine-grain cork involves meticulous stripping, air seasoning, and longer curing periods to enhance elasticity and density, whereas coarse-grain cork undergoes shorter seasoning and less rigorous sorting. These differences in harvesting and processing directly impact the mechanical properties and applications of the cork material.

Physical Properties Comparison

Fine-grain cork exhibits higher density and improved elasticity compared to coarse-grain cork, making it more resistant to compression and deformation. Coarse-grain cork tends to have larger, more irregular cells, resulting in reduced flexibility but enhanced insulation properties. Both types demonstrate excellent thermal and acoustic insulation, though fine-grain cork provides a smoother texture and greater durability in high-stress applications.

Durability and Performance

Fine-grain cork features a denser cellular structure, resulting in enhanced durability and superior resistance to wear compared to coarse-grain cork. Its uniform texture improves compressive strength and dimensional stability, making it ideal for applications requiring long-term performance. In contrast, coarse-grain cork tends to be less resilient and more prone to deformation under stress, limiting its suitability for high-durability uses.

Applications of Fine-Grain Cork

Fine-grain cork is highly valued in luxury applications such as premium wine stoppers and designer accessories due to its uniform texture and superior compressibility. Its fine cellular structure provides enhanced elasticity and impermeability, making it ideal for sealing delicate containers and crafting high-end fashion items. Compared to coarse-grain cork, fine-grain cork offers greater durability and aesthetic appeal, which is crucial for specialized uses in the cork industry.

Applications of Coarse-Grain Cork

Coarse-grain cork, characterized by larger and more pronounced cell structures, is primarily used in applications requiring durability and impact resistance, such as insulation panels and floor underlayments. Its enhanced compressibility and thermal insulation properties make it ideal for construction and automotive sectors where cushioning and vibration dampening are critical. This type of cork also finds use in natural packaging solutions, benefiting from its robust and resilient texture.

Cost and Environmental Impact

Fine-grain cork typically costs more due to its higher quality and durability, making it ideal for premium products like wine stoppers and insulation panels. Coarse-grain cork is less expensive but may require more frequent replacement, potentially increasing long-term costs and environmental waste. Environmentally, fine-grain cork supports sustainable harvesting practices by promoting selective extraction, whereas coarse-grain cork often comes from lower-quality bark with a greater ecological footprint.

Choosing the Right Cork Grain for Your Needs

Fine-grain cork offers a smoother texture and greater flexibility, making it ideal for applications requiring delicate cushioning or detailed craftsmanship. Coarse-grain cork provides superior durability and resilience, better suited for heavy-duty flooring or insulation where robustness is essential. Selecting the right cork grain depends on balancing the need for softness and precision against long-term wear and structural strength.

Fine-grain cork vs Coarse-grain cork Infographic

materialdif.com

materialdif.com