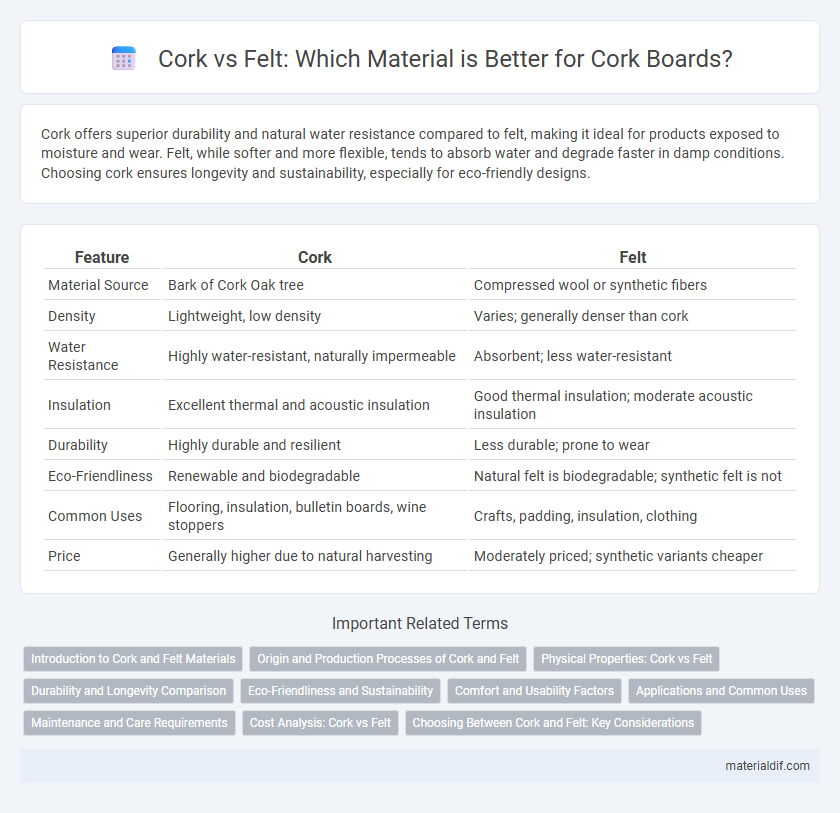

Cork offers superior durability and natural water resistance compared to felt, making it ideal for products exposed to moisture and wear. Felt, while softer and more flexible, tends to absorb water and degrade faster in damp conditions. Choosing cork ensures longevity and sustainability, especially for eco-friendly designs.

Table of Comparison

| Feature | Cork | Felt |

|---|---|---|

| Material Source | Bark of Cork Oak tree | Compressed wool or synthetic fibers |

| Density | Lightweight, low density | Varies; generally denser than cork |

| Water Resistance | Highly water-resistant, naturally impermeable | Absorbent; less water-resistant |

| Insulation | Excellent thermal and acoustic insulation | Good thermal insulation; moderate acoustic insulation |

| Durability | Highly durable and resilient | Less durable; prone to wear |

| Eco-Friendliness | Renewable and biodegradable | Natural felt is biodegradable; synthetic felt is not |

| Common Uses | Flooring, insulation, bulletin boards, wine stoppers | Crafts, padding, insulation, clothing |

| Price | Generally higher due to natural harvesting | Moderately priced; synthetic variants cheaper |

Introduction to Cork and Felt Materials

Cork, harvested from the bark of cork oak trees, offers lightweight, water-resistant, and sustainable properties, making it ideal for eco-friendly applications. Felt, made from compressed fibers such as wool or synthetic materials, provides dense insulation, durability, and flexibility suitable for crafting and industrial uses. Both materials present distinct texture and performance characteristics that influence their selection across various design and manufacturing contexts.

Origin and Production Processes of Cork and Felt

Cork originates from the bark of the Quercus suber tree, predominantly found in the Mediterranean region, with Portugal and Spain leading global production through sustainable harvesting methods that allow the bark to regenerate. Felt is made from natural fibers such as wool, produced worldwide through a process of matting, condensing, and pressing the fibers together, often involving moisture, heat, and agitation to create a dense fabric. Cork harvesting involves stripping the bark without harming the tree, enabling repeated harvests every 9 to 12 years, whereas felt production relies on fiber preparation and mechanical manipulation without a reliance on a specific tree species or region.

Physical Properties: Cork vs Felt

Cork exhibits a lightweight, rigid structure with excellent compressibility and resilience, making it ideal for insulation and cushioning applications. Felt, composed of densely matted fibers, offers superior flexibility and softness, providing enhanced sound absorption and abrasion resistance. Both materials feature natural breathability, but cork's closed-cell structure ensures greater water resistance compared to the porous felt.

Durability and Longevity Comparison

Cork, derived from the bark of the cork oak tree, offers exceptional durability due to its natural resilience and resistance to moisture, making it ideal for long-lasting flooring and insulation. Felt, commonly made from compressed fibers, tends to wear down faster under heavy use and may degrade when exposed to moisture, reducing its lifespan compared to cork. Cork's ability to maintain integrity and resist mold and mildew significantly extends its longevity in applications where durability is critical.

Eco-Friendliness and Sustainability

Cork is a highly sustainable material harvested from the bark of cork oak trees without harming the tree, making it a renewable resource with a low environmental impact. Felt, often made from synthetic fibers, can contribute to pollution and waste due to its non-biodegradable nature and energy-intensive production processes. Choosing cork over felt supports eco-friendly practices by promoting biodegradability, carbon sequestration, and responsible forest management.

Comfort and Usability Factors

Cork offers superior comfort due to its natural elasticity, cushioning impact and conforming to foot shape, which reduces fatigue during prolonged wear. Felt provides excellent insulation and moisture-wicking properties, making it ideal for colder, damp conditions, but lacks the flexibility that cork delivers. Usability factors favor cork in applications requiring durability and shock absorption, while felt excels in lightweight, breathable environments.

Applications and Common Uses

Cork's lightweight, water-resistant, and insulating properties make it ideal for flooring, bulletin boards, wine stoppers, and soundproofing materials, commonly used in construction and home decor. Felt is widely used in crafts, fashion, and industrial applications due to its dense texture, excellent cushioning, and noise reduction capabilities, often found in hats, protective padding, and musical instrument covers. Both materials serve distinct purposes, with cork favored for sustainable building solutions and felt prized in textile and protective product manufacturing.

Maintenance and Care Requirements

Cork flooring requires minimal maintenance, needing only regular sweeping and occasional damp mopping with a pH-balanced cleaner to prevent moisture damage. Felt surfaces demand more frequent cleaning and careful handling to avoid matting and staining, often requiring vacuuming and spot treatment with gentle detergents. Cork's natural resistance to mold and mildew makes it more durable in moist environments compared to felt, which is more sensitive to water exposure and can degrade faster without proper care.

Cost Analysis: Cork vs Felt

Cork and felt differ significantly in cost, with cork typically priced higher due to its natural harvesting process and durability. Felt, often made from synthetic fibers, offers a more affordable option for budget-conscious consumers, though it may lack the longevity of cork. Evaluating the cost-effectiveness of cork versus felt depends on the specific application and long-term durability needs.

Choosing Between Cork and Felt: Key Considerations

When choosing between cork and felt, consider cork's natural water resistance, durability, and eco-friendly properties, making it ideal for flooring and insulation. Felt offers superior cushioning, noise absorption, and versatility, frequently used in furniture padding and crafts. Budget, environmental impact, and intended application largely determine the best material choice for your project in Cork.

Cork vs Felt Infographic

materialdif.com

materialdif.com