Granulated cork is processed into small, uniform particles ideal for insulation and acoustic panels, offering improved versatility and ease of application compared to cork bark. Cork bark is the natural, rugged exterior harvested from cork oak trees, prized for its durability and rustic aesthetic in furniture and flooring. Both forms maintain cork's eco-friendly properties, but granulated cork allows for more flexible industrial and craft uses.

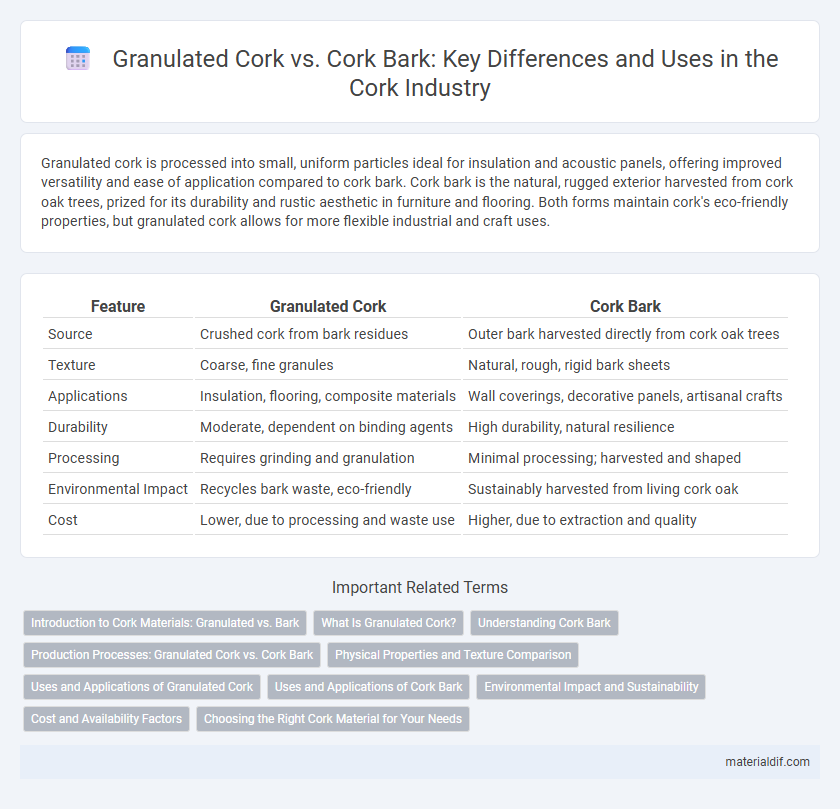

Table of Comparison

| Feature | Granulated Cork | Cork Bark |

|---|---|---|

| Source | Crushed cork from bark residues | Outer bark harvested directly from cork oak trees |

| Texture | Coarse, fine granules | Natural, rough, rigid bark sheets |

| Applications | Insulation, flooring, composite materials | Wall coverings, decorative panels, artisanal crafts |

| Durability | Moderate, dependent on binding agents | High durability, natural resilience |

| Processing | Requires grinding and granulation | Minimal processing; harvested and shaped |

| Environmental Impact | Recycles bark waste, eco-friendly | Sustainably harvested from living cork oak |

| Cost | Lower, due to processing and waste use | Higher, due to extraction and quality |

Introduction to Cork Materials: Granulated vs. Bark

Granulated cork consists of small, processed cork particles often used for insulation, flooring, and sealing applications, offering enhanced flexibility and ease of installation. Cork bark, harvested directly from the cork oak tree, maintains its natural form and texture, making it ideal for traditional cork products such as wine stoppers and bulletin boards. Both materials utilize the unique cellular structure of the cork oak, but granulated cork provides greater versatility for industrial and construction purposes compared to the raw bark form.

What Is Granulated Cork?

Granulated cork consists of small, uniform particles derived from finely ground cork bark, commonly used for insulation, soundproofing, and packaging due to its lightweight and sustainable properties. Unlike cork bark, which is harvested in larger sheets directly from the cork oak tree, granulated cork provides more flexibility in applications, allowing for easier molding and mixing with other materials. Its thermal resistance, elasticity, and eco-friendly nature make granulated cork a popular choice in construction and industrial products.

Understanding Cork Bark

Cork bark is the outer layer of the cork oak tree, harvested through a sustainable process that preserves the tree's health and allows for natural regeneration every nine to twelve years. It possesses a unique cellular structure characterized by airtight and lightweight properties, making it highly durable and resistant to moisture and fire. Understanding cork bark is essential for appreciating its applications in insulation, flooring, and eco-friendly product manufacturing compared to the processed form of granulated cork.

Production Processes: Granulated Cork vs. Cork Bark

Granulated cork is produced by grinding cork bark into small granules after boiling and drying, which enhances its flexibility and removes impurities. Cork bark is harvested directly from the outer layer of cork oak trees, carefully stripped without harming the tree to maintain sustainability. The production process of granulated cork allows for a variety of applications due to its uniform texture, while cork bark retains more of the natural bark structure, making it ideal for traditional cork products.

Physical Properties and Texture Comparison

Granulated cork features smaller, uniform particles that provide a fine, consistent texture ideal for insulation and cushioning applications. Cork bark retains its natural structure with larger, uneven pieces offering greater rigidity and a more rugged, coarse texture, suitable for flooring and decorative uses. The density of granulated cork is lower, making it lightweight and compressible, while cork bark exhibits higher density and durability due to its intact cellular arrangement.

Uses and Applications of Granulated Cork

Granulated cork is widely used in thermal insulation, acoustic panels, and underlayment for flooring due to its superior compressibility and lightweight properties compared to whole cork bark. Its fine, processed form allows for versatile applications in construction, sports equipment, and packaging materials, where durability and flexibility are essential. Granulated cork's ability to absorb vibrations and resist moisture makes it ideal for automotive gaskets and eco-friendly composite materials.

Uses and Applications of Cork Bark

Cork bark, harvested from the Quercus suber tree, is primarily used in applications requiring natural insulation, such as wall coverings, flooring underlays, and acoustic panels, due to its durability and thermal properties. It also finds extensive use in horticulture as mulch and soil conditioner, promoting moisture retention and root protection. Unlike granulated cork, which is often used in composite materials and fillers, cork bark maintains its structural integrity for decorative and functional purposes in sustainable building and gardening solutions.

Environmental Impact and Sustainability

Granulated cork is produced from recycled cork bark, reducing waste and promoting circular economy practices, making it a more sustainable option compared to cork bark, which requires harvesting from cork oak trees and can impact forest ecosystems if not managed responsibly. Cork bark harvesting supports biodiversity by allowing trees to regenerate bark over 9 to 12 years, but excessive or unsustainable harvesting can lead to habitat disruption and reduced carbon sequestration. Overall, granulated cork's utilization of post-harvest residues minimizes environmental impact, while cork bark's sustainability depends on careful forest management and adherence to certification standards like FSC.

Cost and Availability Factors

Granulated cork, derived from mechanically ground cork bark, is generally more affordable due to higher yield and processing efficiency compared to whole cork bark, which requires selective harvesting and manual processing. Availability of granulated cork is greater as it utilizes cork scraps and byproducts, while cork bark depends on the seasonal bark stripping from cork oak trees predominantly in regions like Portugal and Spain. Cost differences also reflect in supply consistency; granulated cork benefits from consistent production cycles, whereas cork bark availability fluctuates with natural tree growth and environmental factors.

Choosing the Right Cork Material for Your Needs

Granulated cork offers superior flexibility and is ideal for insulation, flooring, and craft applications due to its fine texture and ease of molding. Cork bark, harvested directly from cork oak trees, provides a natural, robust material often used in wall coverings, bulletin boards, and eco-friendly products due to its durability and natural aesthetic. Selecting between granulated cork and cork bark depends on the specific application requirements such as texture, flexibility, and strength, with granulated cork favoring detailed work and cork bark suited for structural and decorative uses.

Granulated Cork vs Cork Bark Infographic

materialdif.com

materialdif.com