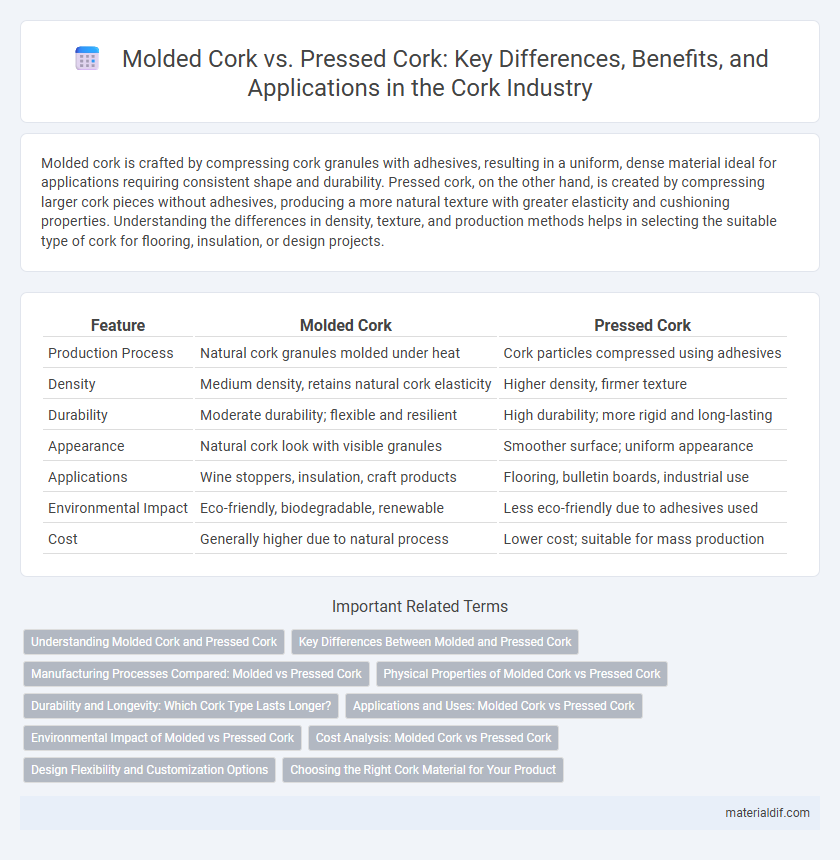

Molded cork is crafted by compressing cork granules with adhesives, resulting in a uniform, dense material ideal for applications requiring consistent shape and durability. Pressed cork, on the other hand, is created by compressing larger cork pieces without adhesives, producing a more natural texture with greater elasticity and cushioning properties. Understanding the differences in density, texture, and production methods helps in selecting the suitable type of cork for flooring, insulation, or design projects.

Table of Comparison

| Feature | Molded Cork | Pressed Cork |

|---|---|---|

| Production Process | Natural cork granules molded under heat | Cork particles compressed using adhesives |

| Density | Medium density, retains natural cork elasticity | Higher density, firmer texture |

| Durability | Moderate durability; flexible and resilient | High durability; more rigid and long-lasting |

| Appearance | Natural cork look with visible granules | Smoother surface; uniform appearance |

| Applications | Wine stoppers, insulation, craft products | Flooring, bulletin boards, industrial use |

| Environmental Impact | Eco-friendly, biodegradable, renewable | Less eco-friendly due to adhesives used |

| Cost | Generally higher due to natural process | Lower cost; suitable for mass production |

Understanding Molded Cork and Pressed Cork

Molded cork is created by compressing cork granules under high pressure to form uniform, dense blocks ideal for insulation and flooring applications. Pressed cork combines cork particles with binders and heat, resulting in a versatile material used for wall coverings and gaskets due to its flexibility and resilience. Understanding these differences helps in selecting the appropriate cork type based on durability, texture, and intended use in construction or design projects.

Key Differences Between Molded and Pressed Cork

Molded cork is produced by compressing cork granules into a uniform shape with the use of heat and pressure, resulting in lightweight, durable, and flexible products ideal for flooring and insulation. Pressed cork, also known as agglomerated cork, involves binding cork granules with adhesive, creating denser and less elastic sheets typically used for bulletin boards and gaskets. Key differences include molded cork's superior elasticity and water resistance compared to the harder, more rigid nature of pressed cork, affecting their applications in various industries.

Manufacturing Processes Compared: Molded vs Pressed Cork

Molded cork is produced by grinding natural cork into granules, then compressing these granules with heat and pressure to form shapes, resulting in a lightweight and flexible material ideal for insulation and flooring. Pressed cork, in contrast, involves finely shredded cork combined with bonding agents, which is then subjected to higher pressure to create denser, more uniform sheets or blocks commonly used for wall coverings and bulletin boards. The choice between molded and pressed cork manufacturing significantly impacts the durability, texture, and application suitability in various industries.

Physical Properties of Molded Cork vs Pressed Cork

Molded cork exhibits a denser, more uniform structure compared to pressed cork, resulting from the compression of cork granules under high pressure and heat. Its superior elasticity and higher tensile strength make it ideal for applications demanding durability and resilience. Pressed cork, being less dense and more porous, offers better flexibility but lower mechanical strength, suitable for lightweight insulation and decorative uses.

Durability and Longevity: Which Cork Type Lasts Longer?

Molded cork, derived from natural cork granules compressed and shaped under heat, offers superior durability and resistance to wear compared to pressed cork, which is made by binding cork particles with adhesives. The natural elasticity and density of molded cork enable it to withstand frequent use and environmental stress, making it longer-lasting for applications such as flooring and wine stoppers. Pressed cork, while more affordable, generally exhibits lower longevity due to its composite nature and weaker structural integrity.

Applications and Uses: Molded Cork vs Pressed Cork

Molded cork is primarily used for making ergonomic products like footwear insoles, gaskets, and decorative items due to its lightweight, flexible, and durable properties. Pressed cork, created from cork granules compressed with binders, is commonly applied in flooring, bulletin boards, and wine stoppers, offering cost-effective insulation and soundproofing. The choice between molded and pressed cork depends on the required density, flexibility, and application-specific performance characteristics.

Environmental Impact of Molded vs Pressed Cork

Molded cork, produced by agglomerating cork granules with natural binders under heat and pressure, offers a lower environmental footprint due to its use of recycled cork waste and minimal chemical additives. Pressed cork, made by compressing cork powder without binders, consumes less energy during manufacturing but may generate more dust and waste material, impacting air quality. Both methods support sustainable cork harvesting, but molded cork's efficient use of byproducts and reduced resource consumption typically result in superior environmental benefits.

Cost Analysis: Molded Cork vs Pressed Cork

Molded cork generally incurs higher production costs due to its advanced manufacturing process involving heat and pressure to shape cork granules into specific forms, resulting in premium pricing compared to pressed cork. Pressed cork, produced by compressing smaller cork particles with binders, offers a more cost-effective solution suitable for large-scale applications requiring less precision. The cost difference between molded cork and pressed cork can significantly impact project budgets, with molded cork favored for durability and aesthetic appeal despite its higher price point.

Design Flexibility and Customization Options

Molded cork offers superior design flexibility due to its ability to be shaped into complex, ergonomic forms, making it ideal for customized product designs and unique applications. Pressed cork, while more uniform and dense, provides consistent texture and is better suited for standardized, flat surfaces with limited customization. Choosing molded cork enhances aesthetic appeal and functional adaptability in innovative cork products.

Choosing the Right Cork Material for Your Product

Molded cork offers higher density and uniformity, making it ideal for products requiring durability and precise shaping, while pressed cork provides a lighter, more flexible option suited for applications needing cushioning and insulation. Selecting the right cork material depends on factors such as intended use, structural requirements, and environmental exposure. Understanding these properties ensures optimal performance and sustainability for cork-based products manufactured in Cork's renowned industry.

Molded cork vs Pressed cork Infographic

materialdif.com

materialdif.com