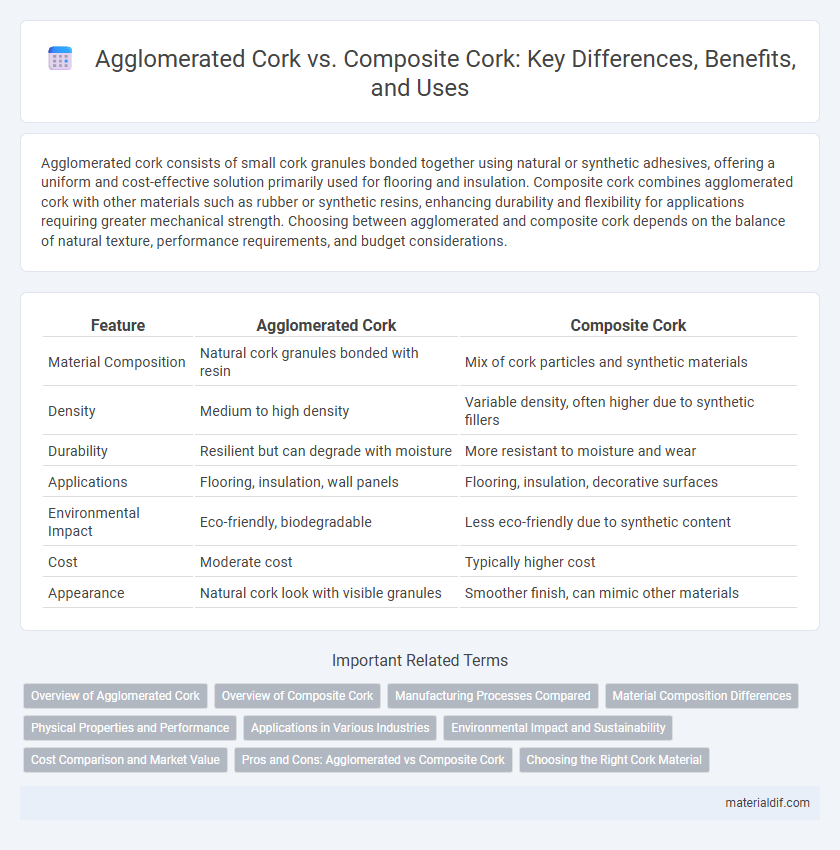

Agglomerated cork consists of small cork granules bonded together using natural or synthetic adhesives, offering a uniform and cost-effective solution primarily used for flooring and insulation. Composite cork combines agglomerated cork with other materials such as rubber or synthetic resins, enhancing durability and flexibility for applications requiring greater mechanical strength. Choosing between agglomerated and composite cork depends on the balance of natural texture, performance requirements, and budget considerations.

Table of Comparison

| Feature | Agglomerated Cork | Composite Cork |

|---|---|---|

| Material Composition | Natural cork granules bonded with resin | Mix of cork particles and synthetic materials |

| Density | Medium to high density | Variable density, often higher due to synthetic fillers |

| Durability | Resilient but can degrade with moisture | More resistant to moisture and wear |

| Applications | Flooring, insulation, wall panels | Flooring, insulation, decorative surfaces |

| Environmental Impact | Eco-friendly, biodegradable | Less eco-friendly due to synthetic content |

| Cost | Moderate cost | Typically higher cost |

| Appearance | Natural cork look with visible granules | Smoother finish, can mimic other materials |

Overview of Agglomerated Cork

Agglomerated cork is produced by bonding cork granules with food-grade adhesives, resulting in a versatile, eco-friendly material commonly used in flooring, insulation, and bulletin boards. Its uniform density and sound-absorbing properties differentiate it from composite cork, which typically blends cork with synthetic materials for enhanced durability. In Cork city and industries, agglomerated cork stands out for sustainable applications due to its recyclability and natural thermal insulation capabilities.

Overview of Composite Cork

Composite cork consists of cork granules bound together using natural or synthetic resins, creating a versatile material with enhanced durability and consistency compared to agglomerated cork. It offers improved mechanical strength and resistance to moisture, making it suitable for applications in flooring, insulation, and sealing where uniformity and performance are critical. The controlled manufacturing process of composite cork ensures a stable texture and density, optimizing its use in industrial and construction settings.

Manufacturing Processes Compared

Agglomerated cork is manufactured by grinding natural cork into granules, which are then bonded together using synthetic or natural adhesives under high pressure and heat, forming a solid block. Composite cork combines natural cork granules with other materials such as resins or polymers to enhance durability and flexibility, using molding techniques that ensure uniformity and resilience. The key difference in manufacturing lies in the raw material preparation and bonding agents, where agglomerated cork relies solely on cork particles, while composite cork integrates additional components for improved performance.

Material Composition Differences

Agglomerated cork consists of small cork granules bonded together using natural or synthetic adhesives, producing a dense and uniform material ideal for insulation and flooring applications. Composite cork combines natural cork with other materials such as rubber, polymers, or resins to enhance flexibility, durability, and water resistance, making it suitable for specialized industrial uses. The primary distinction lies in agglomerated cork's uniform granule-based structure versus composite cork's multi-material hybrid composition tailored for performance enhancement.

Physical Properties and Performance

Agglomerated cork consists of small granules bonded with adhesive, resulting in a denser and more uniform material that offers excellent thermal insulation and sound absorption properties. Composite cork combines natural cork pieces with synthetic resins to enhance mechanical strength, moisture resistance, and durability, making it suitable for flooring and industrial applications. Both materials provide eco-friendly solutions, but agglomerated cork excels in flexibility and cushioning, while composite cork delivers superior hardness and structural stability.

Applications in Various Industries

Agglomerated cork is widely used in construction and flooring industries due to its density, resilience, and thermal insulation properties, making it ideal for wall panels, underlayment, and acoustic insulation. Composite cork combines cork granules with synthetic binders, enhancing flexibility and durability, thus favored in sports equipment, footwear, and automotive components. Both types leverage cork's lightweight, renewable nature but target different industry requirements based on performance and design needs.

Environmental Impact and Sustainability

Agglomerated cork, made from natural cork granules bonded with eco-friendly adhesives, offers superior environmental benefits due to its renewable sourcing and full recyclability. Composite cork combines cork with synthetic materials, resulting in lower biodegradability and a higher carbon footprint. Sustainable cork harvesting practices in agglomerated cork production support biodiversity and promote carbon sequestration, making it a greener choice compared to composite alternatives.

Cost Comparison and Market Value

Agglomerated cork is generally more cost-effective than composite cork due to its lower density and simpler manufacturing process, making it a preferred choice for bulk applications. Composite cork, incorporating adhesive binders with cork granules, offers enhanced durability and aesthetic appeal, resulting in higher market value and suitability for premium interiors. Market trends indicate a growing demand for composite cork in luxury sectors, while agglomerated cork dominates in mass-market and industrial uses due to its affordability.

Pros and Cons: Agglomerated vs Composite Cork

Agglomerated cork, made from granulated cork bark bound with adhesive, offers excellent thermal and acoustic insulation but may have reduced durability and water resistance compared to composite cork. Composite cork combines cork granules with synthetic or natural binders, enhancing mechanical strength and moisture resistance while potentially compromising biodegradability and natural elasticity. Choosing between agglomerated and composite cork depends on application priorities such as environmental impact, durability, and price efficiency.

Choosing the Right Cork Material

Choosing between agglomerated cork and composite cork depends on the intended use and durability requirements. Agglomerated cork, made from granulated cork bonded with adhesive, offers uniformity and cost-effectiveness, making it ideal for flooring and insulation. Composite cork combines natural cork particles with other materials, providing enhanced strength and resistance to wear, suitable for high-traffic or specialized applications.

Agglomerated cork vs Composite cork Infographic

materialdif.com

materialdif.com