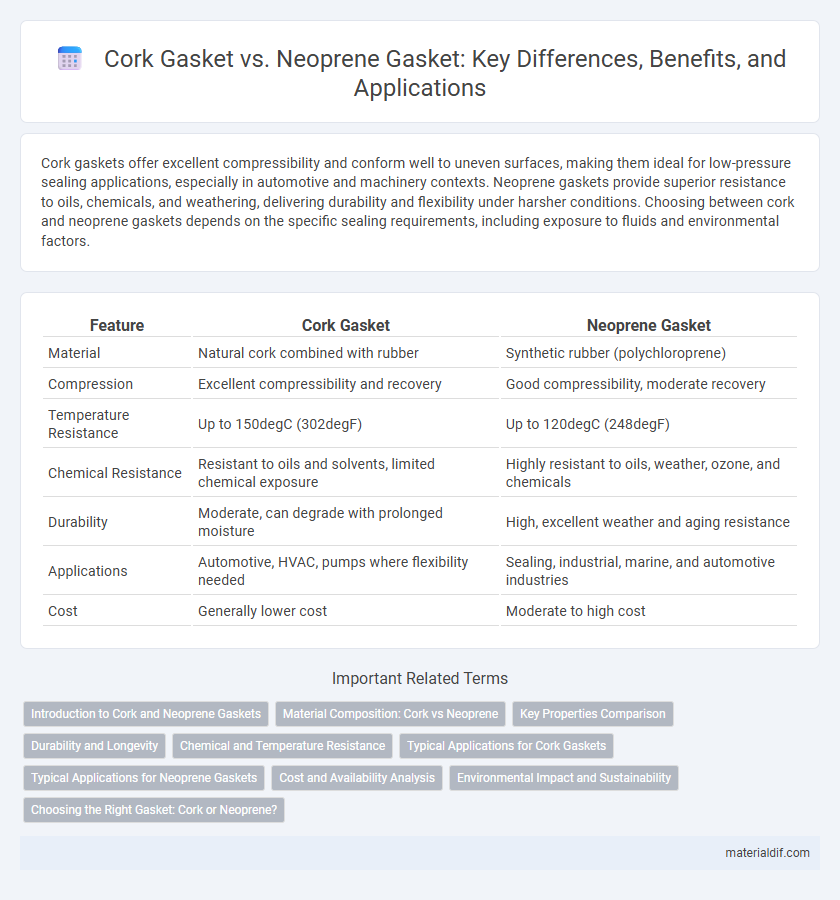

Cork gaskets offer excellent compressibility and conform well to uneven surfaces, making them ideal for low-pressure sealing applications, especially in automotive and machinery contexts. Neoprene gaskets provide superior resistance to oils, chemicals, and weathering, delivering durability and flexibility under harsher conditions. Choosing between cork and neoprene gaskets depends on the specific sealing requirements, including exposure to fluids and environmental factors.

Table of Comparison

| Feature | Cork Gasket | Neoprene Gasket |

|---|---|---|

| Material | Natural cork combined with rubber | Synthetic rubber (polychloroprene) |

| Compression | Excellent compressibility and recovery | Good compressibility, moderate recovery |

| Temperature Resistance | Up to 150degC (302degF) | Up to 120degC (248degF) |

| Chemical Resistance | Resistant to oils and solvents, limited chemical exposure | Highly resistant to oils, weather, ozone, and chemicals |

| Durability | Moderate, can degrade with prolonged moisture | High, excellent weather and aging resistance |

| Applications | Automotive, HVAC, pumps where flexibility needed | Sealing, industrial, marine, and automotive industries |

| Cost | Generally lower cost | Moderate to high cost |

Introduction to Cork and Neoprene Gaskets

Cork gaskets are made from compressed cork particles combined with rubber, offering excellent compressibility, flexibility, and resistance to oil and fuel, making them ideal for sealing uneven surfaces in automotive and industrial applications. Neoprene gaskets, crafted from synthetic rubber, provide superior durability, chemical resistance, and temperature tolerance, commonly used in refrigeration, air conditioning, and marine environments. Both cork and neoprene gaskets serve distinct purposes based on material properties, environmental resistance, and application requirements.

Material Composition: Cork vs Neoprene

Cork gaskets are made from natural cork particles bonded with rubber, offering excellent compressibility and resistance to oils and solvents. Neoprene gaskets consist of synthetic rubber known for superior chemical stability, weather resistance, and durability in extreme temperatures. Comparing material composition, cork provides eco-friendly, flexible sealing solutions, while neoprene delivers enhanced resilience and longevity in harsh environments.

Key Properties Comparison

Cork gaskets excel in compressibility and flexibility, providing excellent sealing for irregular surfaces and heat resistance up to 400degF. Neoprene gaskets offer superior chemical resistance, durability, and weatherproofing, operating effectively between -20degF and 180degF. Cork is ideal for mild-temperature applications with exposed surfaces, while neoprene suits harsh chemical environments and outdoor conditions.

Durability and Longevity

Cork gaskets offer excellent compressibility and flexibility, making them ideal for sealing irregular surfaces, but they tend to degrade faster under continuous exposure to oil and heat. Neoprene gaskets exhibit superior durability and longevity due to their resistance to oils, chemicals, and temperature fluctuations, maintaining integrity in harsher environments. For applications demanding long-term performance, neoprene gaskets outperform cork gaskets by providing enhanced wear resistance and extended service life.

Chemical and Temperature Resistance

Cork gaskets offer excellent resistance to oils, solvents, and mild chemicals, making them suitable for applications involving low to moderate chemical exposure, with temperature tolerance typically up to 115degC (239degF). Neoprene gaskets provide superior chemical resistance against a broader range of chemicals, including acids, alkalies, and ozone, and maintain flexibility under temperatures ranging from -40degC to 120degC (-40degF to 248degF). For high-temperature environments or exposure to aggressive chemicals, neoprene gaskets outperform cork gaskets in durability and long-term stability.

Typical Applications for Cork Gaskets

Cork gaskets are widely used in automotive engines, HVAC systems, and low-pressure fluid sealing due to their excellent compressibility and resistance to oil and solvents. They are ideal for applications requiring a reliable seal under moderate temperature and pressure conditions, such as valve covers, fuel tanks, and carburetors. These gaskets provide effective sealing in static and dynamic environments where flexibility and vibration absorption are essential.

Typical Applications for Neoprene Gaskets

Neoprene gaskets are commonly used in automotive, refrigeration, and marine industries due to their excellent resistance to oils, weathering, and ozone. Their flexibility and durability make them ideal for sealing applications in engines, HVAC units, and outdoor equipment. Neoprene's moderate temperature tolerance and chemical stability ensure reliable performance in dynamic environments where cork gaskets may degrade faster.

Cost and Availability Analysis

Cork gaskets offer a cost-effective solution due to their lower price per sheet and wide availability in local markets, making them ideal for budget-conscious applications. Neoprene gaskets, while generally more expensive, provide superior durability and resistance to oils and weathering, justifying their higher cost in specialized uses. Both materials have robust supply chains, but cork's natural composition ensures easier sourcing in bulk compared to synthetic neoprene, which may face availability fluctuations depending on chemical production trends.

Environmental Impact and Sustainability

Cork gaskets offer superior environmental benefits due to their biodegradability and renewable sourcing from cork oak trees, which also helps reduce deforestation. Neoprene gaskets, derived from synthetic rubber and petrochemicals, present sustainability concerns related to non-renewable resources and limited recyclability. Choosing cork gaskets supports eco-friendly manufacturing practices and lowers carbon footprint in industrial sealing applications.

Choosing the Right Gasket: Cork or Neoprene?

Choosing the right gasket depends on the application's temperature, pressure, and chemical exposure, where cork gaskets offer excellent compressibility and sealing for low-pressure, dry environments, while neoprene gaskets provide superior resistance to oils, solvents, and weathering in moderate to high-pressure conditions. Cork gaskets are ideal for automotive or industrial uses requiring flexibility and vibration damping, whereas neoprene gaskets suit applications needing long-lasting durability in harsh chemical or outdoor settings. Evaluating factors such as sealing effectiveness, environmental resilience, and cost efficiency ensures optimal gasket selection between cork and neoprene materials.

Cork Gasket vs Neoprene Gasket Infographic

materialdif.com

materialdif.com