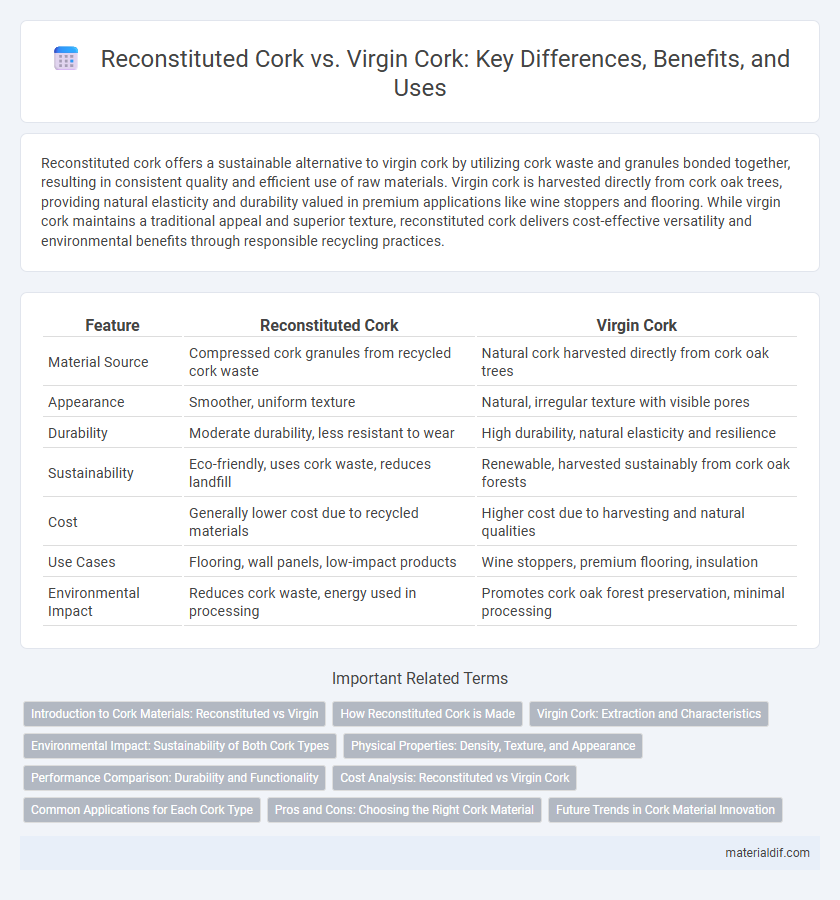

Reconstituted cork offers a sustainable alternative to virgin cork by utilizing cork waste and granules bonded together, resulting in consistent quality and efficient use of raw materials. Virgin cork is harvested directly from cork oak trees, providing natural elasticity and durability valued in premium applications like wine stoppers and flooring. While virgin cork maintains a traditional appeal and superior texture, reconstituted cork delivers cost-effective versatility and environmental benefits through responsible recycling practices.

Table of Comparison

| Feature | Reconstituted Cork | Virgin Cork |

|---|---|---|

| Material Source | Compressed cork granules from recycled cork waste | Natural cork harvested directly from cork oak trees |

| Appearance | Smoother, uniform texture | Natural, irregular texture with visible pores |

| Durability | Moderate durability, less resistant to wear | High durability, natural elasticity and resilience |

| Sustainability | Eco-friendly, uses cork waste, reduces landfill | Renewable, harvested sustainably from cork oak forests |

| Cost | Generally lower cost due to recycled materials | Higher cost due to harvesting and natural qualities |

| Use Cases | Flooring, wall panels, low-impact products | Wine stoppers, premium flooring, insulation |

| Environmental Impact | Reduces cork waste, energy used in processing | Promotes cork oak forest preservation, minimal processing |

Introduction to Cork Materials: Reconstituted vs Virgin

Reconstituted cork is engineered by grinding natural cork waste into granules and binding them with food-grade adhesives, offering a sustainable and cost-effective alternative to virgin cork. Virgin cork is harvested directly from the bark of cork oak trees, providing superior elasticity, durability, and natural grain patterns crucial for premium cork products like wine stoppers. Selecting between reconstituted and virgin cork depends on the desired balance of environmental impact, performance, and aesthetic qualities in applications ranging from flooring to insulation.

How Reconstituted Cork is Made

Reconstituted cork is manufactured by grinding natural cork scraps and granules into small particles, which are then mixed with a binding resin to form composite sheets under heat and pressure. This process allows for the efficient use of cork by-products that would otherwise be discarded, enhancing sustainability in cork production. Virgin cork, by contrast, is harvested directly from the cork oak tree in large, natural sheets without undergoing this reconstitution process.

Virgin Cork: Extraction and Characteristics

Virgin cork is harvested from the bark of Quercus suber trees through a sustainable extraction process that avoids harming the tree, enabling repeated harvests every nine to twelve years. Its natural cellular structure provides superior elasticity, durability, and impermeability, making it ideal for wine stoppers and high-quality insulation. The unprocessed, pure composition of virgin cork ensures consistent performance, a distinctive grain pattern, and enhanced aging properties compared to reconstituted cork.

Environmental Impact: Sustainability of Both Cork Types

Reconstituted cork, made from cork granules and adhesive, maximizes resource use by repurposing cork waste, significantly reducing deforestation and landfill impact compared to virgin cork, which is harvested directly from cork oak bark without tree felling. Virgin cork boasts natural biodegradability and carbon sequestration benefits aligned with sustainable forest management practices, promoting biodiversity and soil health in cork oak ecosystems. Both types support eco-friendly industries, but reconstituted cork offers enhanced sustainability through waste minimization and lower raw material consumption.

Physical Properties: Density, Texture, and Appearance

Reconstituted cork exhibits a more uniform density and smoother texture compared to virgin cork, which naturally displays variable density and a coarser, uneven surface. Virgin cork's appearance features distinct, irregular grain patterns and natural porosity, while reconstituted cork has a consistent color and less visible imperfections due to its engineered composition. The physical differences impact application suitability, with reconstituted cork preferred for uniformity in product manufacturing and virgin cork valued for its authentic natural aesthetics and elasticity.

Performance Comparison: Durability and Functionality

Reconstituted cork offers enhanced uniformity and resistance to moisture compared to virgin cork, making it more durable in environments prone to humidity. Virgin cork retains its natural cellular structure, providing superior elasticity and compressibility, which benefits applications requiring cushioning and insulation. Both materials excel in their performance based on specific use cases, with reconstituted cork favored for consistent strength and virgin cork preferred for natural resilience.

Cost Analysis: Reconstituted vs Virgin Cork

Reconstituted cork offers a cost-effective alternative to virgin cork, with production costs significantly lower due to the use of cork granules and adhesives, reducing raw material expenses. Virgin cork, derived directly from cork oak bark, involves higher harvesting and processing costs, reflecting its premium quality and natural integrity. When evaluating price-performance balance, reconstituted cork is ideal for budget-conscious projects, while virgin cork remains preferred for applications demanding superior durability and aesthetic value.

Common Applications for Each Cork Type

Reconstituted cork, made from cork granules bonded together, is commonly used in flooring, wall panels, and insulation due to its cost-effectiveness and uniform texture. Virgin cork, harvested directly from cork oak bark, is preferred in wine stoppers and high-end acoustic products for its natural elasticity and superior sealing properties. Each cork type serves distinct industries, with reconstituted cork targeting construction and design applications, while virgin cork dominates premium packaging and soundproofing markets.

Pros and Cons: Choosing the Right Cork Material

Reconstituted cork offers consistent quality and sustainability benefits by utilizing cork waste, making it cost-effective and environmentally friendly compared to virgin cork, which is harvested directly from cork oak trees and provides superior natural appearance and durability. However, virgin cork tends to have better elasticity and longevity, ideal for premium applications like wine stoppers, whereas reconstituted cork may exhibit variability in texture and less resilience. Selecting between reconstituted and virgin cork depends on project requirements, balancing performance needs with ecological impact and budget constraints.

Future Trends in Cork Material Innovation

Reconstituted cork, derived from natural cork scraps and granules, is gaining momentum due to its sustainable production and cost efficiency compared to virgin cork harvested directly from cork oak bark. Innovations in adhesive formulations and processing technologies are enhancing the durability and versatility of reconstituted cork, making it a promising alternative in packaging, construction, and fashion industries. Future trends point towards increased integration of bio-based polymers and smart materials to improve performance while minimizing environmental impact.

Reconstituted Cork vs Virgin Cork Infographic

materialdif.com

materialdif.com