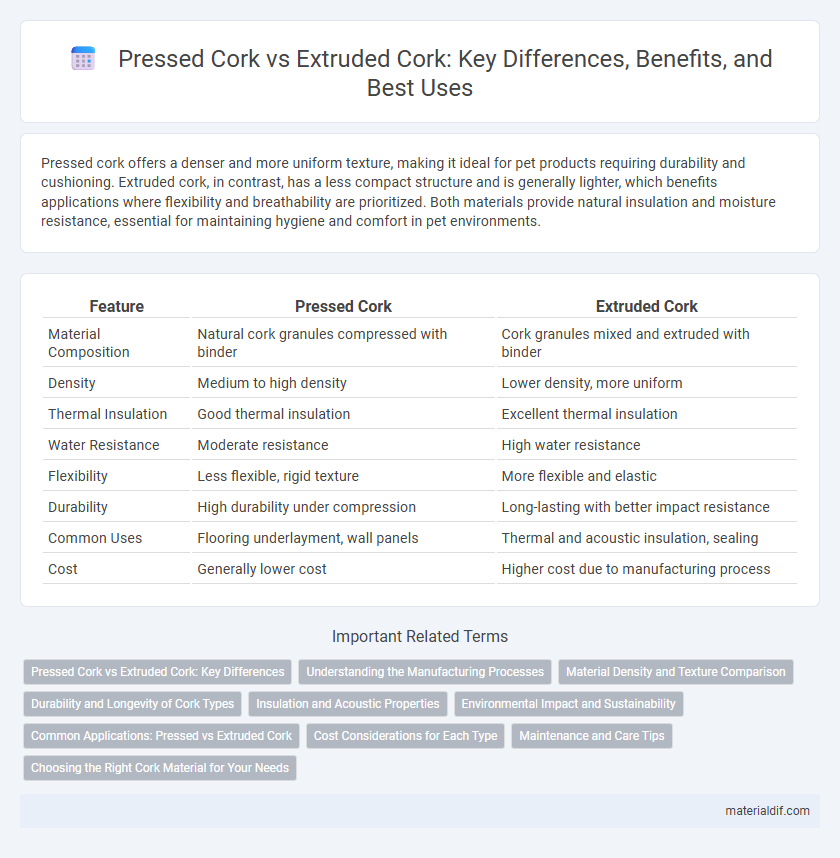

Pressed cork offers a denser and more uniform texture, making it ideal for pet products requiring durability and cushioning. Extruded cork, in contrast, has a less compact structure and is generally lighter, which benefits applications where flexibility and breathability are prioritized. Both materials provide natural insulation and moisture resistance, essential for maintaining hygiene and comfort in pet environments.

Table of Comparison

| Feature | Pressed Cork | Extruded Cork |

|---|---|---|

| Material Composition | Natural cork granules compressed with binder | Cork granules mixed and extruded with binder |

| Density | Medium to high density | Lower density, more uniform |

| Thermal Insulation | Good thermal insulation | Excellent thermal insulation |

| Water Resistance | Moderate resistance | High water resistance |

| Flexibility | Less flexible, rigid texture | More flexible and elastic |

| Durability | High durability under compression | Long-lasting with better impact resistance |

| Common Uses | Flooring underlayment, wall panels | Thermal and acoustic insulation, sealing |

| Cost | Generally lower cost | Higher cost due to manufacturing process |

Pressed Cork vs Extruded Cork: Key Differences

Pressed cork is made by agglomerating natural cork granules with a binding agent under high pressure, resulting in a dense and durable material with excellent insulation and cushioning properties. Extruded cork, on the other hand, is produced by melting cork powder and then shaping it through an extrusion process, creating a more uniform texture and superior water resistance but generally less elasticity compared to pressed cork. The choice between pressed and extruded cork depends on specific application needs, such as thermal insulation, impact absorption, or moisture protection in construction and design projects.

Understanding the Manufacturing Processes

Pressed cork is manufactured by grinding natural cork granules and compressing them with adhesive binders under high pressure and heat, resulting in dense, uniform sheets ideal for flooring and insulation. Extruded cork, on the other hand, involves melting cork powder mixed with binders, then forcing the mixture through a mold to create continuous profiles with controlled density and shape for specialized applications. Understanding these differences highlights how pressed cork offers versatility and cost-effectiveness, while extruded cork provides precise forms and enhanced mechanical properties.

Material Density and Texture Comparison

Pressed cork features a higher material density due to the compression of natural cork granules, resulting in a firmer and more rigid texture ideal for structural applications. In contrast, extruded cork exhibits a lower density with a more uniform and smoother texture, providing excellent insulation properties and flexibility. The difference in density and texture directly influences their suitability for uses such as flooring, wall coverings, and thermal insulation.

Durability and Longevity of Cork Types

Pressed cork exhibits superior durability and longevity compared to extruded cork due to its dense structure formed by compressing natural cork granules with strong adhesives. The natural resilience and cellular integrity of pressed cork enable it to withstand moisture, compression, and temperature fluctuations, making it ideal for flooring and insulation. Conversely, extruded cork, created by melting cork granules and reconstituting them, tends to have a more uniform texture but lower durability, limiting its lifespan in high-stress applications.

Insulation and Acoustic Properties

Pressed cork offers superior insulation and acoustic properties due to its natural cellular structure that traps air, enhancing thermal resistance and sound absorption. Extruded cork, while denser and more uniform, provides slightly lower insulating performance but excels in vibration dampening and mechanical strength. Both types contribute effectively to energy efficiency and noise reduction, with pressed cork favored for superior thermal insulation and extruded cork chosen for durability in structural applications.

Environmental Impact and Sustainability

Pressed cork, produced by agglomerating cork granules with natural binders, exhibits a lower environmental impact due to minimal chemical use and efficient recycling of cork waste, contributing to sustainable forestry practices in cork oak ecosystems. Extruded cork involves melting and shaping between heated rollers, often requiring higher energy input and additives, which may increase its carbon footprint and reduce biodegradability. Sustainable cork production prioritizes preserving cork oak habitats, carbon sequestration, and maintaining biodiversity, with pressed cork generally favored for its eco-friendly attributes.

Common Applications: Pressed vs Extruded Cork

Pressed cork is commonly used for wine stoppers, bulletin boards, and flooring due to its natural texture and flexibility, making it ideal for cushioning and insulation. Extruded cork, produced by agglomerating cork dust with binders, is favored in construction as thermal and acoustic insulation panels and expansion joints due to its consistent density and durability. Both types serve distinct roles where pressed cork excels in compressibility and aesthetics, while extruded cork provides structural strength and uniformity.

Cost Considerations for Each Type

Pressed cork generally offers a more cost-effective solution due to its lower production expenses and efficient use of cork granules, making it ideal for budget-conscious projects. Extruded cork involves higher manufacturing costs, attributed to its denser structure and specialized extrusion process, which often results in a premium price point. Choosing between pressed and extruded cork depends on balancing initial material costs with long-term performance requirements in construction or insulation applications.

Maintenance and Care Tips

Pressed cork requires regular sealing with a suitable cork sealant to prevent moisture absorption and maintain its durability, making it ideal for flooring and wall applications. Extruded cork features a denser composition, which offers enhanced resistance to wear and moisture, reducing maintenance frequency and simplifying care routines. Both types benefit from gentle cleaning with a damp cloth and avoiding harsh chemicals to preserve their natural properties and extend lifespan.

Choosing the Right Cork Material for Your Needs

Pressed cork offers a natural, eco-friendly option with a denser texture ideal for flooring and insulation, providing superior soundproofing and durability. Extruded cork, created by combining cork granules with synthetic resins, is more lightweight and flexible, making it suitable for gaskets, seals, and cushioning applications. Selecting the right cork material depends on factors like application type, required compressibility, and environmental exposure, ensuring optimal performance and longevity.

pressed cork vs extruded cork Infographic

materialdif.com

materialdif.com