Raw cork, harvested directly from the bark of cork oak trees, retains its natural porosity and elasticity, making it ideal for insulation and lightweight applications. Processed cork undergoes treatment and refinement, enhancing durability and water resistance, which suits it for flooring, gaskets, and wine stoppers. Understanding the differences in texture, durability, and application helps in selecting the right type of cork for sustainable and efficient use.

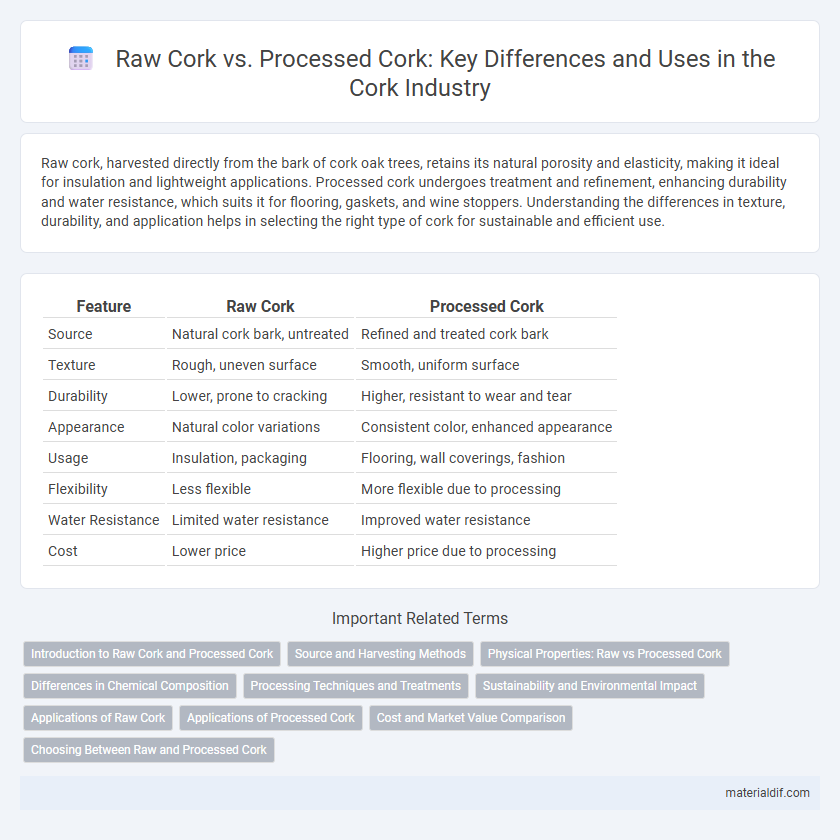

Table of Comparison

| Feature | Raw Cork | Processed Cork |

|---|---|---|

| Source | Natural cork bark, untreated | Refined and treated cork bark |

| Texture | Rough, uneven surface | Smooth, uniform surface |

| Durability | Lower, prone to cracking | Higher, resistant to wear and tear |

| Appearance | Natural color variations | Consistent color, enhanced appearance |

| Usage | Insulation, packaging | Flooring, wall coverings, fashion |

| Flexibility | Less flexible | More flexible due to processing |

| Water Resistance | Limited water resistance | Improved water resistance |

| Cost | Lower price | Higher price due to processing |

Introduction to Raw Cork and Processed Cork

Raw cork, harvested from the bark of cork oak trees primarily in Portugal and Spain, retains its natural cellular structure, offering superior elasticity and breathability for applications like insulation and flooring. Processed cork undergoes treatments such as boiling, sanding, and lamination to enhance durability, uniformity, and aesthetic appeal, making it ideal for products like wine stoppers, flooring tiles, and fashion accessories. The distinction between raw and processed cork is crucial for industries relying on cork's unique properties, where raw cork emphasizes natural performance and processed cork emphasizes refined functionality.

Source and Harvesting Methods

Raw cork is harvested directly from the outer bark of Quercus suber trees, primarily found in Mediterranean regions like Portugal and Spain, through a sustainable stripping process every 9 to 12 years. This natural extraction preserves the tree's growth, allowing cork to regenerate without damage. Processed cork involves thermal and mechanical treatments to transform raw cork into agglomerated sheets or granules, enhancing uniformity and durability for commercial products.

Physical Properties: Raw vs Processed Cork

Raw cork features a natural cellular structure that offers superior elasticity, lightweight properties, and excellent thermal insulation. Processed cork, enhanced through treatments like granulation and agglomeration, provides increased density, improved durability, and uniformity in texture for specialized applications. The physical differences impact the suitability of raw cork for cushioning and insulation, while processed cork is often preferred in flooring, sealing, and composite materials.

Differences in Chemical Composition

Raw cork contains higher concentrations of suberin, lignin, and tannins, which contribute to its natural resilience and impermeability. Processed cork undergoes treatments that reduce phenolic compounds and volatile organic compounds, enhancing its stability and reducing odor. These chemical alterations increase the suitability of processed cork for industrial applications like flooring and insulation.

Processing Techniques and Treatments

Raw cork is harvested directly from the cork oak tree and retains its natural properties, including porosity and elasticity, but contains impurities and uneven textures. Processed cork undergoes treatments such as boiling, drying, and pressing to remove tannins, improve durability, and enhance consistency in density and color. Advanced techniques like granulation and agglomeration enable the creation of composite cork products with tailored mechanical and insulating properties.

Sustainability and Environmental Impact

Raw cork is harvested directly from the bark of cork oak trees without harming the tree, enabling sustainable extraction cycles every 9 to 12 years, which supports biodiversity and carbon sequestration. Processed cork products undergo treatments such as boiling, grinding, and binding, sometimes involving synthetic additives that may affect biodegradability and increase environmental footprint. The sustainable advantage of raw cork lies in its natural, renewable source and minimal processing, while processed cork balances usability with potential ecological trade-offs from manufacturing stages.

Applications of Raw Cork

Raw cork, harvested directly from the cork oak tree, is primarily used in applications requiring natural insulation, such as in building materials and thermal barriers due to its lightweight and fire-resistant properties. Its cellular structure makes it ideal for acoustic insulation in recording studios and automotive components, providing effective sound dampening. Raw cork is also employed in horticulture as a soil conditioner and mulch, benefiting plant moisture retention and aeration.

Applications of Processed Cork

Processed cork offers enhanced flexibility, durability, and water resistance compared to raw cork, making it ideal for diverse applications in industries such as construction, automotive, and fashion. It is commonly used in flooring, insulation panels, gaskets, and footwear, leveraging its lightweight and thermal properties. The ability to be molded and combined with other materials expands its use in eco-friendly products and advanced design solutions.

Cost and Market Value Comparison

Raw cork, harvested directly from the cork oak tree, is generally less expensive due to minimal processing but has limited market value because of its rough texture and inconsistent quality. Processed cork undergoes cleaning, boiling, and shaping, enhancing durability and appearance, which significantly increases both production costs and retail prices. The market favors processed cork products for premium uses like flooring and wine stoppers, reflecting higher consumer demand and better profit margins.

Choosing Between Raw and Processed Cork

Raw cork, harvested directly from cork oak trees, retains its natural porous structure, making it highly breathable and ideal for insulation or crafts requiring flexibility. Processed cork undergoes treatments like grinding, compressing, or bonding, enhancing durability and allowing customization for flooring, bulletin boards, and gaskets. Choosing between raw and processed cork depends on the intended application's need for natural texture versus engineered strength and consistency.

Raw cork vs Processed cork Infographic

materialdif.com

materialdif.com