Granulated cork offers flexibility and cost-effectiveness by being made from compressed cork particles, making it ideal for insulation and lightweight applications. Solid cork provides superior durability and natural resilience, often preferred for flooring and high-impact usage where strength and aesthetic appeal are essential. Choosing between granulated and solid cork depends on project requirements such as structural integrity and budget considerations.

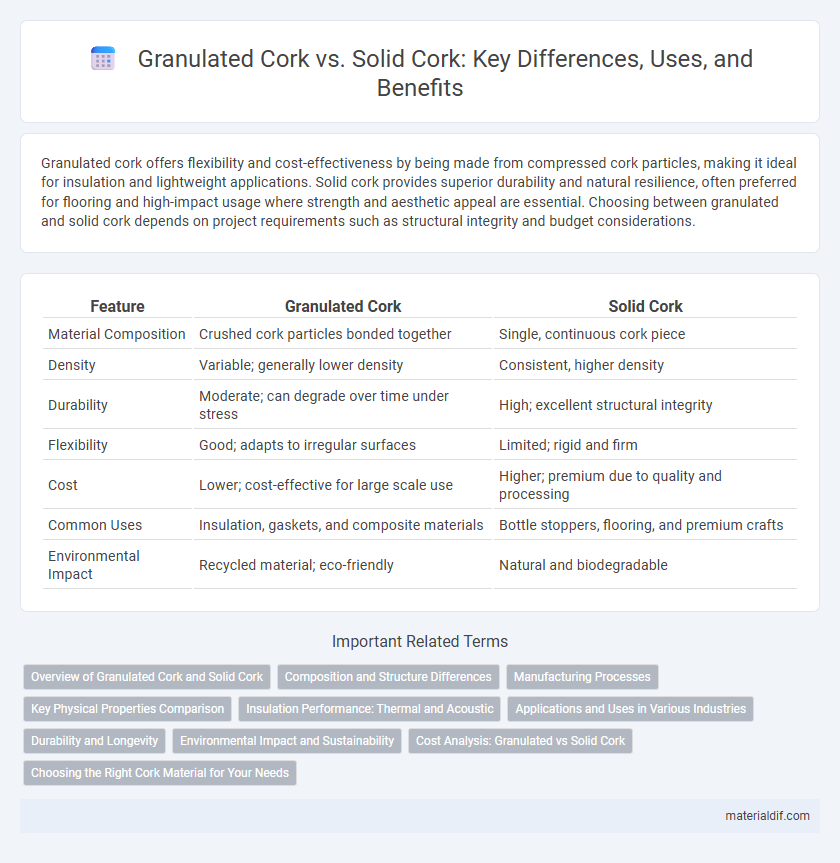

Table of Comparison

| Feature | Granulated Cork | Solid Cork |

|---|---|---|

| Material Composition | Crushed cork particles bonded together | Single, continuous cork piece |

| Density | Variable; generally lower density | Consistent, higher density |

| Durability | Moderate; can degrade over time under stress | High; excellent structural integrity |

| Flexibility | Good; adapts to irregular surfaces | Limited; rigid and firm |

| Cost | Lower; cost-effective for large scale use | Higher; premium due to quality and processing |

| Common Uses | Insulation, gaskets, and composite materials | Bottle stoppers, flooring, and premium crafts |

| Environmental Impact | Recycled material; eco-friendly | Natural and biodegradable |

Overview of Granulated Cork and Solid Cork

Granulated cork consists of small, compressed particles derived from natural cork, offering flexibility and cost-effectiveness for insulation and cushioning applications in Cork. Solid cork is a single piece of natural cork bark, prized for its durability, water resistance, and structural integrity, commonly used in flooring and bottle stoppers. Both types maintain Cork's sustainable and lightweight properties, with granulated cork favoring versatility and solid cork providing superior resilience.

Composition and Structure Differences

Granulated cork is composed of small, crushed cork particles bonded together, creating a flexible and lightweight material with an open-cell structure that enhances insulation and sound absorption. Solid cork consists of a single piece of bark harvested from the cork oak tree, maintaining its natural cellular arrangement, which provides durability, elasticity, and water resistance. The primary structural difference lies in granulated cork's composite nature versus the intact, uniform cellular matrix of solid cork, influencing their respective mechanical properties and applications.

Manufacturing Processes

Granulated cork is produced by grinding leftover cork stoppers or slabs into small particles, which are then compressed and bonded using natural or synthetic resins to create agglomerated cork products. Solid cork, on the other hand, is directly harvested from the cork oak tree's bark and processed into blocks or sheets without significant alteration, preserving its natural cellular structure. The manufacturing process of granulated cork allows for greater resource efficiency by utilizing cork waste, while solid cork requires careful debarking and quality control to maintain its durability and elasticity.

Key Physical Properties Comparison

Granulated cork consists of agglomerated cork particles offering high elasticity and compression resistance, making it ideal for insulation and gasketing applications. Solid cork, derived from a single piece of cork bark, exhibits superior durability, tensile strength, and thermal insulation, suitable for flooring and wine stoppers. Key physical differences include granulated cork's enhanced flexibility and breathability versus solid cork's greater density and moisture resistance.

Insulation Performance: Thermal and Acoustic

Granulated cork offers superior thermal insulation due to its porous structure, effectively reducing heat transfer and maintaining temperature stability. Solid cork provides excellent acoustic insulation by absorbing sound waves, minimizing noise transmission in buildings. Both materials leverage cork's natural cellular properties, but granulated cork excels in thermal performance while solid cork is preferred for soundproofing applications.

Applications and Uses in Various Industries

Granulated cork is extensively used in construction and industrial applications due to its excellent insulation, lightweight nature, and flexibility, making it ideal for thermal and acoustic insulation panels, flooring underlayment, and vibration dampening. Solid cork, prized for its durability and natural elasticity, is commonly utilized in wine stoppers, fishing rod handles, footwear, and fashion accessories, offering a premium finish and moisture resistance. Both types of cork are sustainably sourced and valued in automotive, aerospace, and design industries for their eco-friendly properties and versatile performance.

Durability and Longevity

Granulated cork, composed of compressed cork particles, offers flexibility and excellent shock absorption but tends to wear down faster under heavy use compared to solid cork. Solid cork, harvested from a single piece of cork bark, provides superior durability and longer lifespan, making it ideal for high-traffic areas or applications requiring sustained performance. Its dense cellular structure enhances resistance to compression and moisture, ensuring greater longevity in flooring and insulation products.

Environmental Impact and Sustainability

Granulated cork, produced by recycling cork waste, significantly reduces landfill usage and minimizes raw material extraction, enhancing sustainability compared to solid cork, which involves harvesting whole bark strips from cork oak trees. Both materials are biodegradable and renewable, but granulated cork supports circular economy practices by repurposing cork residues, lowering carbon footprint during production. The environmental impact of granulated cork is further lessened due to reduced energy consumption and waste generation, making it a preferred eco-friendly choice for insulation and flooring applications in Cork.

Cost Analysis: Granulated vs Solid Cork

Granulated cork offers a cost advantage over solid cork due to its production from cork waste and lower material density, resulting in cheaper manufacturing and transportation expenses. Solid cork, sourced from premium cork bark, commands higher prices because of its durability, uniformity, and superior insulation properties. Cost analysis reveals granulated cork suits budget-conscious projects while solid cork remains preferred for applications demanding premium quality and longevity.

Choosing the Right Cork Material for Your Needs

Granulated cork offers excellent flexibility and cost-efficiency, making it ideal for insulation, flooring, and lightweight applications, whereas solid cork provides superior durability and water resistance, perfect for high-traffic areas and premium products. Understanding the specific requirements of your project, such as compression strength and moisture exposure, is crucial in selecting between granulated and solid cork. Opting for the right cork material enhances performance, longevity, and overall satisfaction in construction, design, or manufacturing processes.

Granulated cork vs Solid cork Infographic

materialdif.com

materialdif.com