Burnished cork features a smooth, polished surface that enhances its natural beauty while making it more resistant to wear and water damage. Raw cork retains its natural, rough texture, offering a more rustic appearance but requires extra care to prevent crumbling and staining. For pet products, burnished cork is often preferred due to its durability and ease of cleaning, ensuring a longer-lasting and hygienic option.

Table of Comparison

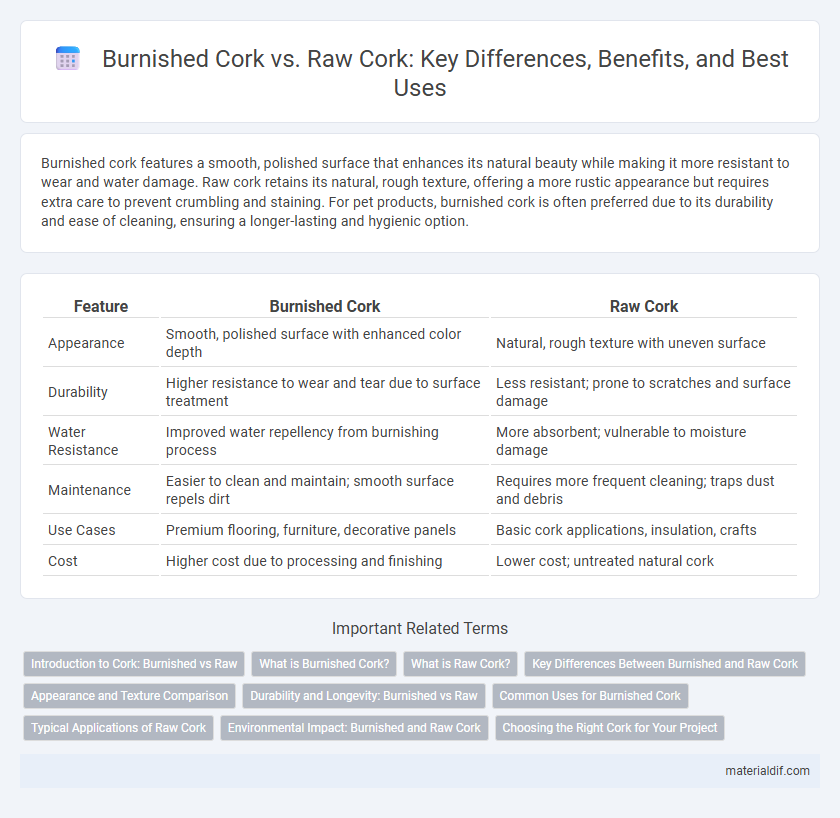

| Feature | Burnished Cork | Raw Cork |

|---|---|---|

| Appearance | Smooth, polished surface with enhanced color depth | Natural, rough texture with uneven surface |

| Durability | Higher resistance to wear and tear due to surface treatment | Less resistant; prone to scratches and surface damage |

| Water Resistance | Improved water repellency from burnishing process | More absorbent; vulnerable to moisture damage |

| Maintenance | Easier to clean and maintain; smooth surface repels dirt | Requires more frequent cleaning; traps dust and debris |

| Use Cases | Premium flooring, furniture, decorative panels | Basic cork applications, insulation, crafts |

| Cost | Higher cost due to processing and finishing | Lower cost; untreated natural cork |

Introduction to Cork: Burnished vs Raw

Burnished cork features a polished surface that enhances its natural texture and increases durability, making it ideal for decorative applications and flooring. Raw cork retains its natural, porous structure, offering superior breathability and insulation properties, which are essential for acoustic panels and sustainable packaging. The choice between burnished and raw cork depends on specific functional needs, with burnished cork providing aesthetic appeal and raw cork ensuring eco-friendly performance.

What is Burnished Cork?

Burnished cork is cork material that has been polished and treated to create a smooth, glossy surface, enhancing its durability and aesthetic appeal compared to raw cork. Unlike raw cork, which retains its natural rough texture and porous appearance, burnished cork undergoes a finishing process that seals the surface, reducing absorption and making it more resistant to wear and stains. This treatment makes burnished cork ideal for high-traffic areas and stylish design applications in flooring, wall coverings, and furniture.

What is Raw Cork?

Raw cork is the natural, untreated bark harvested from the cork oak tree, maintaining its original porous texture and earthy appearance. Unlike burnished cork, which undergoes a polishing process to enhance smoothness and color depth, raw cork retains its rustic, rugged surface ideal for eco-friendly products and insulation materials. Its high cellular structure provides excellent elasticity, thermal insulation, and water resistance, making it a sustainable choice for various applications in flooring, fashion, and construction.

Key Differences Between Burnished and Raw Cork

Burnished cork features a smooth, polished surface achieved through heat and pressure, enhancing its durability and water resistance compared to raw cork, which retains a rougher texture and more porous nature. The burnishing process compresses the cork cells, resulting in increased density and a more refined aesthetic, while raw cork maintains its natural, earthy appearance and greater breathability. Key distinctions include burnished cork's superior stain resistance and ease of cleaning versus raw cork's potential for higher absorption and natural cushioning properties.

Appearance and Texture Comparison

Burnished cork exhibits a smooth, polished surface with a rich, deep color that enhances its natural grain patterns, making it ideal for decorative applications. Raw cork retains a rougher texture and lighter, more natural beige tone, preserving its organic, rustic appeal. The tactile experience of burnished cork is sleek and refined, while raw cork feels coarse and porous, emphasizing its unprocessed character.

Durability and Longevity: Burnished vs Raw

Burnished cork exhibits enhanced durability due to its polished, sealed surface which provides increased resistance to moisture, wear, and abrasion compared to raw cork. Raw cork, while naturally resilient, tends to absorb moisture and dirt more readily, leading to faster degradation and reduced longevity in high-traffic or humid environments. The longevity of burnished cork surfaces can extend several years beyond raw cork, making it a preferable choice for flooring and furniture exposed to frequent use.

Common Uses for Burnished Cork

Burnished cork is commonly used in interior design for wall coverings, flooring, and decorative accents due to its smooth, polished finish that enhances aesthetic appeal and durability. It is favored in eco-friendly furniture making and luxury packaging, where its refined texture adds a sophisticated touch. The surface treatment also improves resistance to moisture and wear, making burnished cork ideal for high-traffic or humid environments.

Typical Applications of Raw Cork

Raw cork is widely utilized in insulation, packaging, and gaskets due to its natural elasticity, impermeability, and thermal resistance. Its unprocessed texture makes it ideal for flooring underlayment and acoustic panels, where sound absorption and cushioning are essential. In industrial settings, raw cork serves as a cost-effective sealing material in valves and expansion joints.

Environmental Impact: Burnished and Raw Cork

Burnished cork undergoes a polishing process that enhances its appearance but requires additional energy and chemicals, slightly increasing its environmental footprint compared to raw cork. Raw cork, harvested directly from cork oak trees without extensive processing, retains its natural properties and offers a lower environmental impact by minimizing energy use and chemical treatments. Both types contribute to sustainable forestry, but raw cork provides a greener option through reduced processing and maintained biodegradability.

Choosing the Right Cork for Your Project

Burnished cork offers a smooth, polished finish ideal for high-end flooring and decorative applications, providing enhanced durability and a refined aesthetic compared to raw cork. Raw cork retains its natural texture and porous quality, making it suitable for eco-friendly insulation, soundproofing, and craft projects where a rustic appearance is desired. Selecting between burnished and raw cork depends on your project's need for either sophisticated design and resilience or natural appearance and functional insulation.

burnished cork vs raw cork Infographic

materialdif.com

materialdif.com