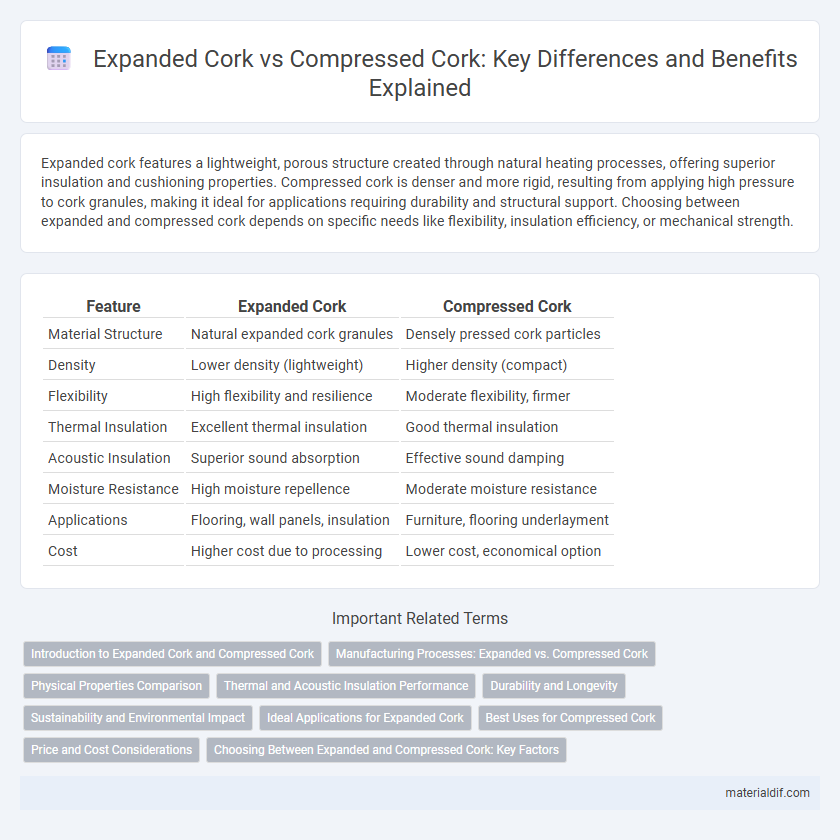

Expanded cork features a lightweight, porous structure created through natural heating processes, offering superior insulation and cushioning properties. Compressed cork is denser and more rigid, resulting from applying high pressure to cork granules, making it ideal for applications requiring durability and structural support. Choosing between expanded and compressed cork depends on specific needs like flexibility, insulation efficiency, or mechanical strength.

Table of Comparison

| Feature | Expanded Cork | Compressed Cork |

|---|---|---|

| Material Structure | Natural expanded cork granules | Densely pressed cork particles |

| Density | Lower density (lightweight) | Higher density (compact) |

| Flexibility | High flexibility and resilience | Moderate flexibility, firmer |

| Thermal Insulation | Excellent thermal insulation | Good thermal insulation |

| Acoustic Insulation | Superior sound absorption | Effective sound damping |

| Moisture Resistance | High moisture repellence | Moderate moisture resistance |

| Applications | Flooring, wall panels, insulation | Furniture, flooring underlayment |

| Cost | Higher cost due to processing | Lower cost, economical option |

Introduction to Expanded Cork and Compressed Cork

Expanded cork originates from natural cork granules heated and expanded to create a lightweight, insulated material widely used in construction and design. Compressed cork is produced by compressing cork particles with binders to form dense, durable blocks ideal for flooring and soundproofing. Both materials offer eco-friendly solutions, but expanded cork excels in thermal insulation while compressed cork provides superior structural strength.

Manufacturing Processes: Expanded vs. Compressed Cork

Expanded cork is produced by heating cork granules in a boiler, causing the suberin to soften and the granules to expand and fuse naturally without binders, resulting in a lightweight, elastic material ideal for insulation and cushioning. Compressed cork involves mixing cork granules with synthetic or natural binders, then applying heat and pressure to form dense, rigid boards suitable for flooring and industrial applications. The manufacturing process of expanded cork prioritizes natural expansion and fusion, while compressed cork relies on binding agents and mechanical pressure for structural integrity.

Physical Properties Comparison

Expanded cork exhibits a porous and lighter structure with excellent thermal and acoustic insulation properties, while compressed cork is denser, offering higher mechanical strength and durability. The elasticity of expanded cork allows for superior shock absorption, whereas compressed cork provides enhanced resistance to wear and tear. Both types maintain natural water resistance, but expanded cork's cellular structure contributes to better breathability compared to the compact nature of compressed cork.

Thermal and Acoustic Insulation Performance

Expanded cork offers superior thermal insulation due to its natural cellular structure, which traps air effectively, reducing heat transfer and enhancing energy efficiency. Compressed cork, while denser and more rigid, provides excellent acoustic insulation by dampening sound vibrations and reducing noise transmission in buildings. Both materials exploit cork's intrinsic properties, but expanded cork excels in thermal applications, whereas compressed cork is preferred for soundproofing solutions.

Durability and Longevity

Expanded cork exhibits superior durability compared to compressed cork due to its natural cellular structure that enhances resistance to wear and tear. The longevity of expanded cork is significantly higher, maintaining its elasticity and insulating properties over extended periods even in varying humidity and temperature conditions. Compressed cork, while denser, tends to degrade faster under mechanical stress and environmental exposure, making expanded cork the preferred choice for applications demanding prolonged durability.

Sustainability and Environmental Impact

Expanded cork offers superior sustainability due to its natural harvesting process, which involves minimally damaging the cork oak tree bark, allowing it to regenerate over time. Compressed cork, while also eco-friendly, undergoes a binding process using natural resins or adhesives that can introduce minor environmental concerns. Both materials provide renewable, biodegradable alternatives to synthetic foam, but expanded cork's production maintains a lower carbon footprint and better preserves ecosystem health.

Ideal Applications for Expanded Cork

Expanded cork offers superior thermal insulation and soundproofing properties due to its natural cellular structure, making it ideal for building insulation and acoustic panels. Its lightweight and flexible nature suits packaging applications where shock absorption and cushioning are critical. Compared to compressed cork, expanded cork also excels in decorative finishes and flooring, providing durability with an attractive, natural appearance.

Best Uses for Compressed Cork

Compressed cork, made by bonding granulated cork with adhesives under heat and pressure, offers superior density and durability compared to expanded cork. It is ideal for flooring, underlayment, and insulation in both residential and commercial buildings due to its enhanced mechanical strength and moisture resistance. Its uniform texture and compressive strength also make it suitable for industrial applications such as gaskets and vibration dampening pads.

Price and Cost Considerations

Expanded cork typically commands a higher price due to its superior elasticity, durability, and water resistance, making it a premium choice for flooring and insulation applications. Compressed cork is more cost-effective, offering budget-friendly solutions with adequate performance for basic uses such as bulletin boards and simple gaskets. When evaluating price and cost considerations, expanded cork's long-term value justifies the upfront investment, whereas compressed cork suits projects with strict financial constraints.

Choosing Between Expanded and Compressed Cork: Key Factors

Expanded cork offers superior insulation and water resistance due to its natural cellular structure, making it ideal for thermal and acoustic applications. Compressed cork, characterized by its denser form from granulated cork particles, provides enhanced durability and structural strength for flooring and wall panels. Selecting between expanded and compressed cork depends on specific requirements such as insulation efficiency, mechanical resilience, and aesthetic preferences in construction or design projects.

expanded cork vs compressed cork Infographic

materialdif.com

materialdif.com