Cork oak bark is the natural outer layer harvested from cork oak trees, prized for its renewable, biodegradable properties and unique cellular structure that provides excellent insulation and elasticity. Cork composites combine cork oak bark with other materials, enhancing durability and versatility for applications such as flooring, insulation panels, and decorative finishes. While natural cork offers superior breathability and sustainability, cork composites improve mechanical strength and design flexibility, making both essential for eco-friendly building solutions.

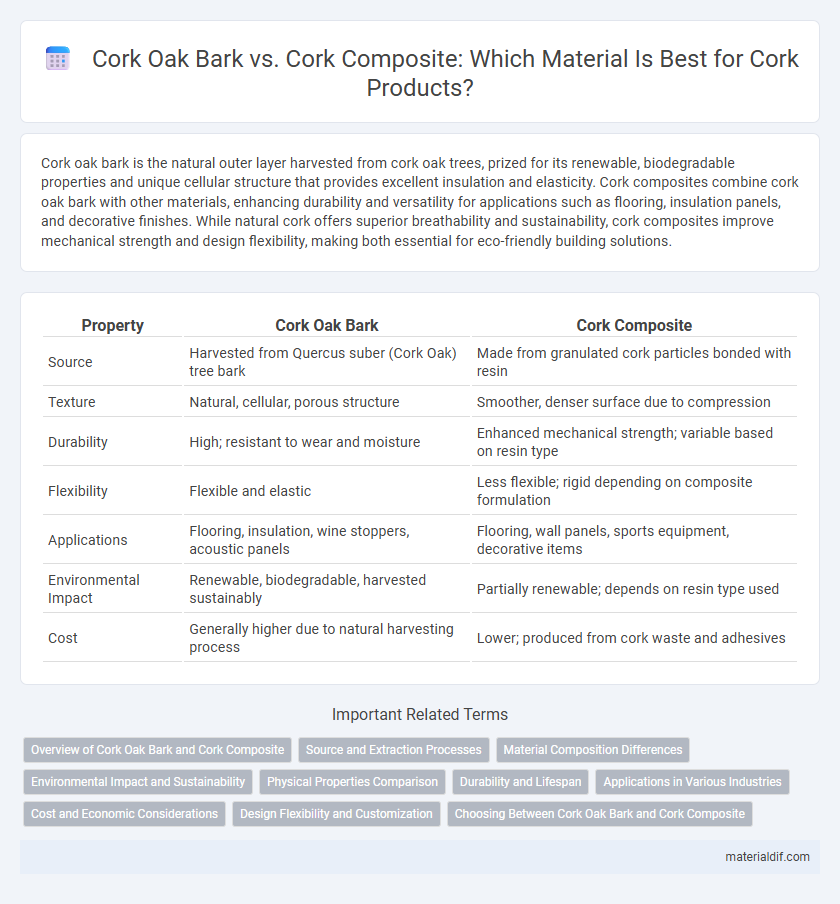

Table of Comparison

| Property | Cork Oak Bark | Cork Composite |

|---|---|---|

| Source | Harvested from Quercus suber (Cork Oak) tree bark | Made from granulated cork particles bonded with resin |

| Texture | Natural, cellular, porous structure | Smoother, denser surface due to compression |

| Durability | High; resistant to wear and moisture | Enhanced mechanical strength; variable based on resin type |

| Flexibility | Flexible and elastic | Less flexible; rigid depending on composite formulation |

| Applications | Flooring, insulation, wine stoppers, acoustic panels | Flooring, wall panels, sports equipment, decorative items |

| Environmental Impact | Renewable, biodegradable, harvested sustainably | Partially renewable; depends on resin type used |

| Cost | Generally higher due to natural harvesting process | Lower; produced from cork waste and adhesives |

Overview of Cork Oak Bark and Cork Composite

Cork oak bark, harvested sustainably from Quercus suber trees, is a natural, renewable material prized for its elasticity, thermal insulation, and moisture resistance. Cork composite, made by binding cork granules with resin or other adhesives, enhances durability and structural integrity while maintaining lightweight and insulating properties. Both materials leverage cork's cellular structure but differ in texture and application versatility, with natural bark favored in traditional uses and composites preferred for engineered products and building components.

Source and Extraction Processes

Cork oak bark, harvested from the Quercus suber tree predominantly found in Mediterranean regions, is stripped manually every 9 to 12 years without harming the tree, preserving its natural regenerative ability. The extraction process for cork oak bark involves careful debarking techniques that maintain bark integrity, ensuring sustainable yield for products like wine stoppers. In contrast, cork composite is produced by agglomerating granulated cork pieces using synthetic or natural binders, sourced from leftover cork waste, which allows for efficient utilization of materials and diverse applications.

Material Composition Differences

Cork oak bark is a natural material harvested from the Quercus suber tree, consisting mainly of suberin, lignin, and polysaccharides, which provide lightweight, elastic, and water-resistant properties. Cork composites combine natural cork particles with synthetic resins or binders, enhancing mechanical strength and durability for industrial applications while sacrificing some natural elasticity. The material composition difference lies in pure cork's organic cellular structure versus the hybrid matrix of cork composites, which influences their respective environmental impact and functional performance.

Environmental Impact and Sustainability

Cork oak bark is a renewable and biodegradable material harvested sustainably from living cork oak trees without harming them, promoting carbon sequestration and biodiversity. Cork composite, made by combining cork granules with synthetic binders, offers durability but may involve non-renewable materials and limited recyclability, impacting its overall environmental footprint. The natural cork oak bark's low environmental impact and regenerative harvesting make it a superior sustainable choice compared to cork composite alternatives.

Physical Properties Comparison

Cork oak bark exhibits exceptional elasticity, lightweight characteristics, and natural resilience, making it highly effective for insulation and cushioning applications. Cork composite, created by agglomerating cork granules with binders, offers enhanced durability, increased compressive strength, and better resistance to wear and moisture. The physical properties of cork composite tend to be more uniform and customizable, whereas cork oak bark maintains superior breathability and natural thermal regulation.

Durability and Lifespan

Cork oak bark, harvested from the Quercus suber tree, offers exceptional durability due to its natural cellular structure, allowing it to withstand moisture, compression, and wear over several decades. Cork composite materials, while designed to mimic these properties, typically have a reduced lifespan and less resistance to environmental stressors because they combine cork granules with synthetic binders. The inherent resilience of natural cork oak bark ensures superior longevity, making it more suitable for applications requiring sustained durability.

Applications in Various Industries

Cork oak bark, harvested sustainably from Quercus suber, offers natural resilience and is primarily used in wine stoppers, flooring, and insulation due to its lightweight, fire-resistant, and moisture-repellent properties. Cork composites, combining cork granules with synthetic or natural binders, extend applications to automotive panels, sports equipment, and acoustic panels by enhancing durability and flexibility. The versatility of cork materials supports eco-friendly solutions across construction, fashion, and aerospace sectors, promoting sustainability and performance.

Cost and Economic Considerations

Natural cork oak bark remains the primary source for premium cork products due to its renewable harvesting and higher material quality, though its extraction involves substantial labor costs and longer processing times. Cork composite, made from smaller cork granules combined with resins, offers a more cost-effective alternative with lower raw material expenses and faster production cycles, appealing to mass-market applications. Economic considerations favor cork composite for budget-sensitive projects, while cork oak bark maintains a premium position justified by its durability and environmental sustainability.

Design Flexibility and Customization

Cork oak bark offers natural variation and texture that enhances design authenticity, while cork composite enables precise shaping and uniformity for tailored applications. Cork composites allow for greater customization in color, density, and thickness, supporting innovative architectural and interior design solutions. The combination of these materials provides designers with versatile options to balance organic aesthetics with functional requirements in sustainable projects.

Choosing Between Cork Oak Bark and Cork Composite

Choosing between cork oak bark and cork composite hinges on durability and sustainability priorities; cork oak bark offers natural elasticity, superior breathability, and biodegradability due to its organic origin from Quercus suber trees. Cork composite, engineered by fusing cork granules with binders, provides enhanced structural strength and consistency, ideal for industrial applications demanding uniformity and resistance to wear. Evaluating the environmental impact reveals cork oak bark as the more eco-friendly option, while cork composite excels in customizable performance and longevity.

cork oak bark vs cork composite Infographic

materialdif.com

materialdif.com