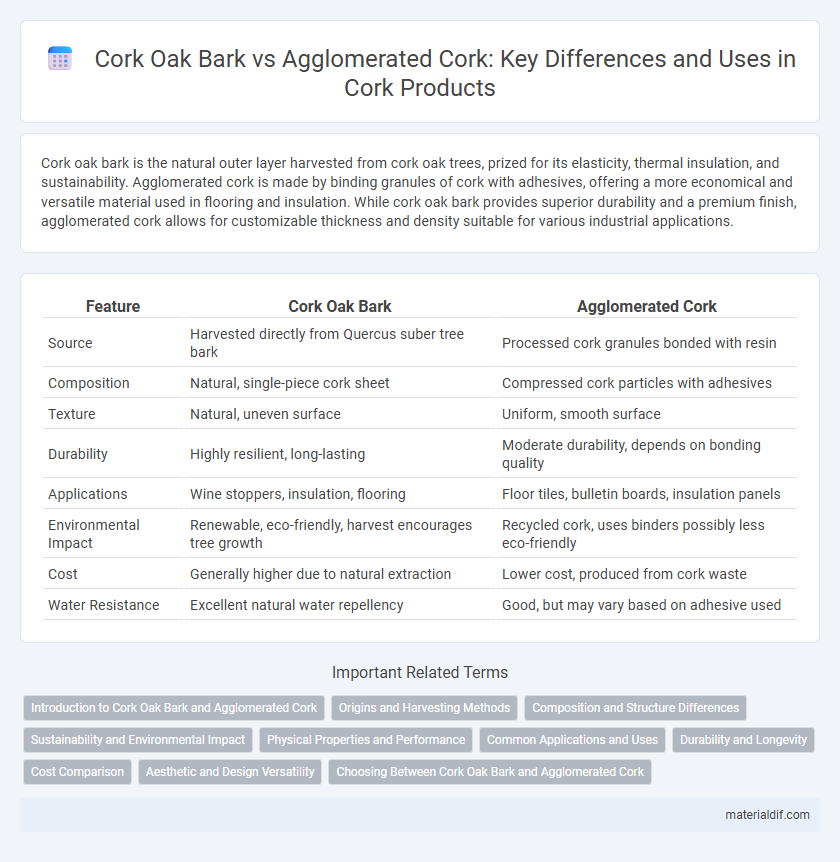

Cork oak bark is the natural outer layer harvested from cork oak trees, prized for its elasticity, thermal insulation, and sustainability. Agglomerated cork is made by binding granules of cork with adhesives, offering a more economical and versatile material used in flooring and insulation. While cork oak bark provides superior durability and a premium finish, agglomerated cork allows for customizable thickness and density suitable for various industrial applications.

Table of Comparison

| Feature | Cork Oak Bark | Agglomerated Cork |

|---|---|---|

| Source | Harvested directly from Quercus suber tree bark | Processed cork granules bonded with resin |

| Composition | Natural, single-piece cork sheet | Compressed cork particles with adhesives |

| Texture | Natural, uneven surface | Uniform, smooth surface |

| Durability | Highly resilient, long-lasting | Moderate durability, depends on bonding quality |

| Applications | Wine stoppers, insulation, flooring | Floor tiles, bulletin boards, insulation panels |

| Environmental Impact | Renewable, eco-friendly, harvest encourages tree growth | Recycled cork, uses binders possibly less eco-friendly |

| Cost | Generally higher due to natural extraction | Lower cost, produced from cork waste |

| Water Resistance | Excellent natural water repellency | Good, but may vary based on adhesive used |

Introduction to Cork Oak Bark and Agglomerated Cork

Cork oak bark, harvested sustainably from Quercus suber trees, is prized for its natural elasticity, waterproof properties, and durability, making it ideal for premium cork products. Agglomerated cork is manufactured by binding granules of natural cork oak bark with adhesives, creating a versatile and cost-effective material often used in flooring, insulation, and soundproofing. Both materials originate from cork oak bark but differ in processing, resulting in distinct applications and performance characteristics.

Origins and Harvesting Methods

Cork oak bark, derived from Quercus suber trees native to the Mediterranean region, is sustainably harvested every 9 to 12 years through a careful stripping process that preserves the tree's health and promotes continuous bark regeneration. Agglomerated cork, on the other hand, is produced by binding granules of natural cork bark using food-grade adhesives, utilizing leftover cork pieces and offcuts from the primary bark harvest, thereby maximizing resource efficiency. Both materials originate from cork oak forests but differ significantly in processing techniques and applications.

Composition and Structure Differences

Cork oak bark consists of natural, cellular suberin-rich tissues harvested from Quercus suber trees, offering a porous, elastic structure that provides superior insulation and durability. Agglomerated cork is manufactured by binding granules of cork bark with synthetic or natural adhesives, resulting in a denser, less uniform material with altered mechanical properties. While cork oak bark retains its original cellular architecture ensuring resilience and flexibility, agglomerated cork compromises some of these characteristics due to the compressive process and adhesive content.

Sustainability and Environmental Impact

Cork oak bark harvesting is a natural, renewable process that preserves trees and supports biodiversity while maintaining carbon sequestration, making it highly sustainable. Agglomerated cork, produced by binding cork granules with adhesives, consumes more energy and involves synthetic materials, resulting in a higher environmental footprint. Both products contribute to cork industry waste reduction, but natural cork oak bark offers superior eco-friendly benefits due to minimal processing and longer product lifespan.

Physical Properties and Performance

Cork oak bark exhibits superior elasticity, natural cellular structure, and resilience, offering excellent compressibility and recovery, ideal for insulation and cushioning applications. Agglomerated cork, produced by binding cork granules with adhesive, provides more uniform density and enhanced mechanical strength, making it suitable for industrial and construction uses requiring consistent performance. Physical properties such as water resistance, thermal insulation, and acoustic dampening are generally higher in cork oak bark, whereas agglomerated cork excels in durability and structural stability.

Common Applications and Uses

Cork oak bark is primarily harvested for natural cork stoppers used in wine bottles, insulation panels, and artisanal crafts due to its elasticity and impermeability. Agglomerated cork, produced by binding cork granules with adhesive, finds common applications in flooring, bulletin boards, and thermal or acoustic insulation products where uniformity and cost-efficiency are essential. Both materials leverage cork's natural thermal resistance and lightweight properties but cater to distinct markets based on processing and material consistency.

Durability and Longevity

Cork oak bark, harvested from the cork oak tree (Quercus suber), is renowned for its exceptional durability and natural resistance to wear, moisture, and fire, making it ideal for long-lasting applications such as flooring and insulation. Agglomerated cork, produced by compressing cork granules with binders, offers good durability but generally has a shorter lifespan and reduced resilience compared to natural cork oak bark. The inherent cellular structure of cork oak bark ensures superior longevity, while agglomerated cork's durability depends heavily on the quality of binders and manufacturing processes.

Cost Comparison

Cork oak bark harvesting involves manual labor and sustainable practices, making raw cork bark more expensive due to limited supply and natural growth cycles. Agglomerated cork, produced by binding cork granules with adhesives, offers a cost-effective alternative with lower production costs and enhanced material efficiency. The price difference reflects the balance between natural authenticity in cork oak bark and the affordability and versatility of agglomerated cork products.

Aesthetic and Design Versatility

Cork oak bark offers a natural, unique texture with rich, organic patterns that enhance aesthetic appeal in interior design. Agglomerated cork provides greater design versatility due to its uniform appearance and ability to be dyed or patterned, allowing customized finishes for modern decor. Each material caters to different stylistic preferences, with cork oak bark emphasizing authenticity and agglomerated cork excelling in adaptability.

Choosing Between Cork Oak Bark and Agglomerated Cork

Cork oak bark, harvested sustainably from Quercus suber trees, offers superior natural elasticity, breathability, and natural resilience, making it ideal for high-end flooring and premium insulation. Agglomerated cork, produced by binding granulated cork oak bark with resin, provides cost-effective durability and uniformity suited for large-scale construction and industrial applications. Choosing between cork oak bark and agglomerated cork depends on specific needs such as aesthetic quality, environmental impact, and budget constraints.

Cork oak bark vs Agglomerated cork Infographic

materialdif.com

materialdif.com