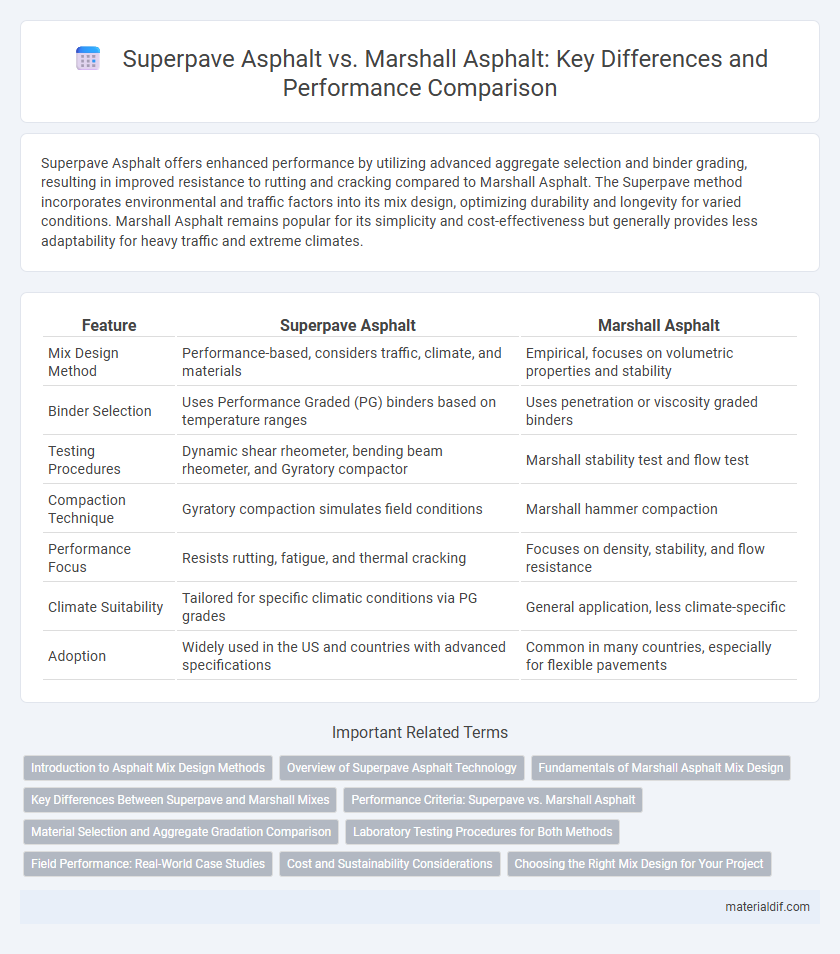

Superpave Asphalt offers enhanced performance by utilizing advanced aggregate selection and binder grading, resulting in improved resistance to rutting and cracking compared to Marshall Asphalt. The Superpave method incorporates environmental and traffic factors into its mix design, optimizing durability and longevity for varied conditions. Marshall Asphalt remains popular for its simplicity and cost-effectiveness but generally provides less adaptability for heavy traffic and extreme climates.

Table of Comparison

| Feature | Superpave Asphalt | Marshall Asphalt |

|---|---|---|

| Mix Design Method | Performance-based, considers traffic, climate, and materials | Empirical, focuses on volumetric properties and stability |

| Binder Selection | Uses Performance Graded (PG) binders based on temperature ranges | Uses penetration or viscosity graded binders |

| Testing Procedures | Dynamic shear rheometer, bending beam rheometer, and Gyratory compactor | Marshall stability test and flow test |

| Compaction Technique | Gyratory compaction simulates field conditions | Marshall hammer compaction |

| Performance Focus | Resists rutting, fatigue, and thermal cracking | Focuses on density, stability, and flow resistance |

| Climate Suitability | Tailored for specific climatic conditions via PG grades | General application, less climate-specific |

| Adoption | Widely used in the US and countries with advanced specifications | Common in many countries, especially for flexible pavements |

Introduction to Asphalt Mix Design Methods

Superpave Asphalt and Marshall Asphalt represent two prominent mix design methods in pavement engineering, each with unique criteria for performance optimization. Superpave emphasizes performance-based specifications tailored to climatic and loading conditions, using advanced testing to enhance durability and rut resistance. Marshall mix design relies on empirical data focused on stability and flow values to achieve optimal compaction and strength for road surfaces.

Overview of Superpave Asphalt Technology

Superpave Asphalt technology incorporates advanced performance-based specifications and testing methods that improve pavement durability and resistance to rutting and cracking under varying climatic conditions. Unlike the traditional Marshall Asphalt method, Superpave utilizes optimized aggregate gradation and binder selection through a rigorous mix design process tailored to traffic loading and environmental stresses. This technology enhances long-term pavement performance and cost-efficiency by addressing specific performance criteria rather than relying solely on empirical data.

Fundamentals of Marshall Asphalt Mix Design

Marshall Asphalt Mix Design fundamentally relies on measuring the stability and flow of asphalt mixtures under controlled conditions to ensure durability and performance. It involves determining the optimal binder content by analyzing the relationship between density, air voids, and stability to achieve a balanced mix resistant to deformation and cracking. This method contrasts with Superpave, which uses performance-based criteria and advanced testing for traffic and climate adaptability.

Key Differences Between Superpave and Marshall Mixes

Superpave asphalt employs performance-based criteria and advanced testing methods to optimize mix design for varying climatic and traffic conditions, while Marshall asphalt relies on empirical methods focused on stability and flow values. Superpave incorporates aggregate gradation, binder selection, and volumetric properties to improve durability and resistance to rutting and cracking. Marshall mix design typically emphasizes simplicity and ease of use but may lack the adaptability and precision of Superpave in addressing complex pavement performance requirements.

Performance Criteria: Superpave vs. Marshall Asphalt

Superpave asphalt outperforms Marshall asphalt by utilizing advanced performance-based criteria, including rutting resistance, fatigue cracking, and thermal cracking, tailored to specific climate and traffic conditions. Unlike the empirical Marshall method, Superpave incorporates binder rheology and aggregate gradation in its mix design, optimizing durability and load-bearing capacity. This results in improved pavement lifespan and reduced maintenance costs under diverse environmental stresses.

Material Selection and Aggregate Gradation Comparison

Superpave asphalt utilizes a performance-based mix design that emphasizes selecting aggregates with specific shape, texture, and size distribution to enhance durability and resistance to rutting and cracking. In contrast, Marshall asphalt relies on a volumetric approach with broader aggregate gradation limits, often resulting in less optimized particle packing and lower overall performance under high traffic loads. The Superpave system's precise aggregate gradation ensures improved mechanical interlock and resilience, making it preferable for modern pavement stresses compared to the Marshall method.

Laboratory Testing Procedures for Both Methods

Superpave asphalt laboratory testing employs the Gyratory Compactor for sample preparation, providing enhanced simulation of field conditions and refined measurement of volumetric properties compared to Marshall's Static Compaction method. Superpave specifically uses the Dynamic Shear Rheometer (DSR) and Bending Beam Rheometer (BBR) to assess asphalt binder performance at various temperatures, whereas Marshall testing relies primarily on stability and flow tests to evaluate mix strength and plastic deformation resistance. The advanced performance grading system in Superpave enables more precise assessment of temperature susceptibility and long-term durability, which are less explicitly addressed in traditional Marshall procedures.

Field Performance: Real-World Case Studies

Superpave asphalt demonstrates superior field performance compared to Marshall asphalt, particularly in resisting rutting and thermal cracking under heavy traffic and extreme temperature variations. Case studies from states like Texas and Pennsylvania reveal that Superpave pavements show extended durability and lower maintenance costs over a ten-year period. Marshall asphalt, while effective under moderate conditions, often experiences premature failures in high-stress environments due to less advanced mix design criteria.

Cost and Sustainability Considerations

Superpave Asphalt typically offers better long-term cost efficiency due to its enhanced performance under varying traffic loads and environmental conditions, reducing maintenance expenses. In terms of sustainability, Superpave's use of advanced binder modification allows for increased recycling of reclaimed asphalt pavement (RAP), lowering raw material consumption and environmental impact. Marshall Asphalt, while initially less expensive and simpler to produce, often incurs higher life-cycle costs and has limited compatibility with recycled materials, making it less sustainable over time.

Choosing the Right Mix Design for Your Project

Selecting between Superpave Asphalt and Marshall Asphalt depends on project-specific factors like traffic load, climate conditions, and longevity requirements. Superpave offers enhanced performance through advanced grading and is ideal for high-traffic, extreme temperature areas, while Marshall Asphalt remains cost-effective for moderate traffic and simpler pavements. Evaluating the pavement's structural needs and environmental stresses ensures the optimal mix design for durability and cost-efficiency.

Superpave Asphalt vs Marshall Asphalt Infographic

materialdif.com

materialdif.com