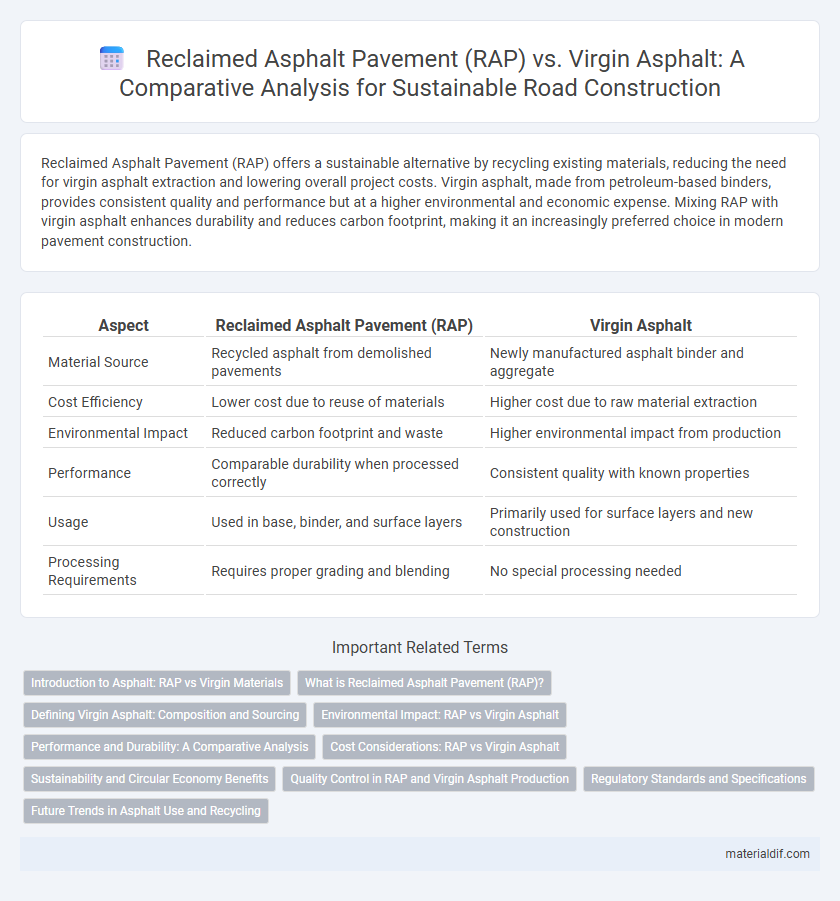

Reclaimed Asphalt Pavement (RAP) offers a sustainable alternative by recycling existing materials, reducing the need for virgin asphalt extraction and lowering overall project costs. Virgin asphalt, made from petroleum-based binders, provides consistent quality and performance but at a higher environmental and economic expense. Mixing RAP with virgin asphalt enhances durability and reduces carbon footprint, making it an increasingly preferred choice in modern pavement construction.

Table of Comparison

| Aspect | Reclaimed Asphalt Pavement (RAP) | Virgin Asphalt |

|---|---|---|

| Material Source | Recycled asphalt from demolished pavements | Newly manufactured asphalt binder and aggregate |

| Cost Efficiency | Lower cost due to reuse of materials | Higher cost due to raw material extraction |

| Environmental Impact | Reduced carbon footprint and waste | Higher environmental impact from production |

| Performance | Comparable durability when processed correctly | Consistent quality with known properties |

| Usage | Used in base, binder, and surface layers | Primarily used for surface layers and new construction |

| Processing Requirements | Requires proper grading and blending | No special processing needed |

Introduction to Asphalt: RAP vs Virgin Materials

Reclaimed Asphalt Pavement (RAP) comprises recycled materials reclaimed from old and existing asphalt surfaces, offering sustainable and cost-effective alternatives to virgin asphalt binders and aggregates. Virgin asphalt is produced from fresh petroleum crude oil distillation and provides consistent quality and performance but involves higher environmental and economic costs. RAP's integration into new asphalt mixes reduces natural resource consumption and greenhouse gas emissions while maintaining structural integrity and durability when processed appropriately.

What is Reclaimed Asphalt Pavement (RAP)?

Reclaimed Asphalt Pavement (RAP) is recycled asphalt material derived from milling or removing existing asphalt pavements during road construction or maintenance. RAP consists of crushed asphalt mixtures containing aggregates and aged binder that can be reused in new asphalt mixtures. Utilizing RAP reduces the demand for virgin materials, lowers costs, and supports sustainable construction practices.

Defining Virgin Asphalt: Composition and Sourcing

Virgin asphalt consists of petroleum-derived bitumen sourced directly from crude oil refining, characterized by its uniform chemical composition and superior purity compared to recycled materials. It includes aggregates selected for optimal size and quality to ensure consistent performance in pavement applications. The controlled sourcing and manufacturing processes guarantee predictable binder properties, making virgin asphalt the benchmark for new pavement construction and high-performance overlays.

Environmental Impact: RAP vs Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) significantly reduces environmental impact by minimizing the demand for new raw materials and decreasing energy consumption during production compared to virgin asphalt. Utilizing RAP lowers greenhouse gas emissions by up to 50% and diverts millions of tons of pavement waste from landfills annually. Conversely, virgin asphalt extraction and processing contribute to higher carbon footprints and resource depletion, emphasizing the sustainability advantages of RAP in modern road construction.

Performance and Durability: A Comparative Analysis

Reclaimed Asphalt Pavement (RAP) enhances pavement performance by integrating recycled materials that maintain structural integrity while reducing costs and environmental impact. Virgin asphalt offers consistent quality and predictable durability but often lacks the sustainability advantages of RAP. Comparative studies show RAP mixtures can match or exceed virgin asphalt in resistance to cracking and rutting when properly processed and incorporated.

Cost Considerations: RAP vs Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) offers significant cost savings compared to virgin asphalt due to reduced material and transportation expenses, often lowering project costs by up to 30%. The reuse of RAP minimizes the need for new raw materials, which are subject to market price volatility, making RAP a more economically stable option. However, careful evaluation of RAP content levels is necessary to maintain pavement quality without compromising long-term performance and associated maintenance costs.

Sustainability and Circular Economy Benefits

Reclaimed Asphalt Pavement (RAP) significantly reduces the demand for virgin asphalt materials, lowering greenhouse gas emissions and conserving natural resources. Incorporating RAP promotes a circular economy by enabling the reuse of existing pavement materials, which decreases landfill waste and energy consumption associated with asphalt production. Studies show RAP usage can cut production energy by up to 40%, enhancing sustainability in road construction projects.

Quality Control in RAP and Virgin Asphalt Production

Reclaimed Asphalt Pavement (RAP) quality control involves rigorous testing for gradation, binder content, moisture levels, and contaminants to ensure consistency and performance comparable to virgin asphalt. Virgin asphalt production relies on controlled mixing of aggregates and fresh binder with precise temperature control to maintain optimal binder properties and pavement durability. Implementing stringent quality control protocols in both RAP and virgin asphalt enhances pavement longevity and reduces the risk of premature failures.

Regulatory Standards and Specifications

Reclaimed Asphalt Pavement (RAP) must comply with strict regulatory standards such as ASTM D6757 and AASHTO M 323, which specify limits on RAP content to ensure quality and durability in road construction. Virgin asphalt is often subject to more consistent specifications regarding binder performance grades (PG) outlined by the Superpave system, offering predictability in performance under varying climatic conditions. Regulatory agencies increasingly encourage RAP usage within specified thresholds to promote sustainability while maintaining safety and functional standards in pavement design.

Future Trends in Asphalt Use and Recycling

Reclaimed Asphalt Pavement (RAP) is becoming increasingly integral to sustainable road construction due to its environmental benefits and cost efficiency compared to virgin asphalt, which relies on fresh bitumen and aggregates. Future trends emphasize enhanced recycling technologies like warm mix asphalt and innovative binders that improve RAP integration without compromising pavement durability or performance. Growing regulatory support and advancements in processing methods are expected to drive higher RAP content in asphalt mixes, reducing the demand for virgin materials and lowering the carbon footprint of road infrastructure.

Reclaimed Asphalt Pavement (RAP) vs Virgin Asphalt Infographic

materialdif.com

materialdif.com