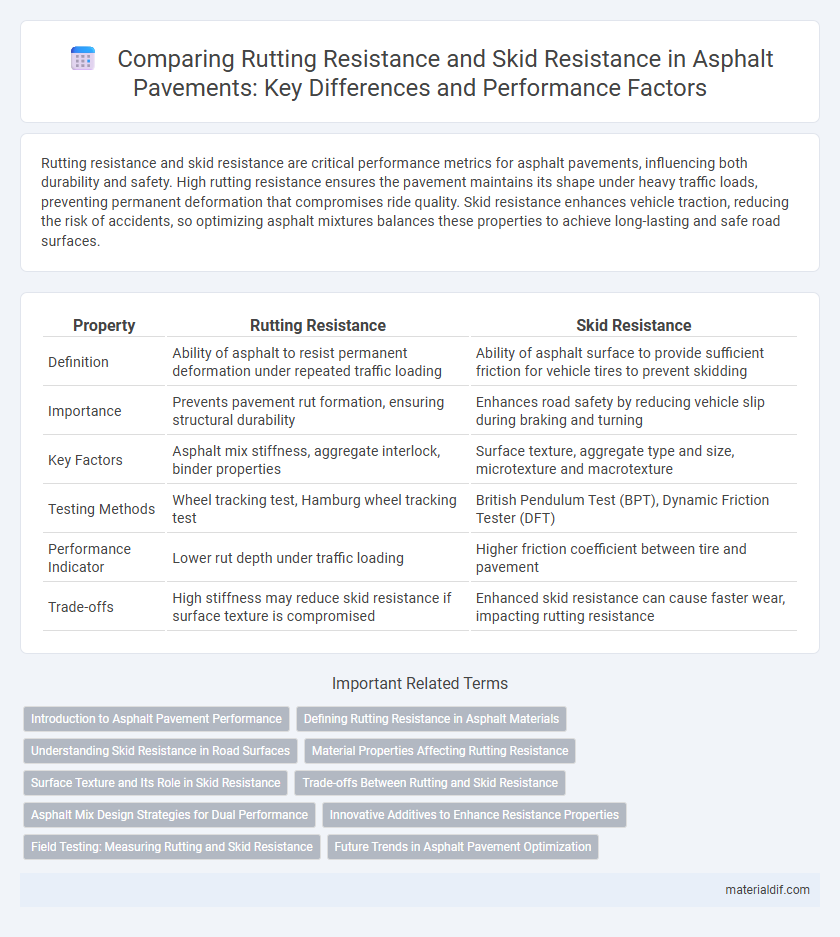

Rutting resistance and skid resistance are critical performance metrics for asphalt pavements, influencing both durability and safety. High rutting resistance ensures the pavement maintains its shape under heavy traffic loads, preventing permanent deformation that compromises ride quality. Skid resistance enhances vehicle traction, reducing the risk of accidents, so optimizing asphalt mixtures balances these properties to achieve long-lasting and safe road surfaces.

Table of Comparison

| Property | Rutting Resistance | Skid Resistance |

|---|---|---|

| Definition | Ability of asphalt to resist permanent deformation under repeated traffic loading | Ability of asphalt surface to provide sufficient friction for vehicle tires to prevent skidding |

| Importance | Prevents pavement rut formation, ensuring structural durability | Enhances road safety by reducing vehicle slip during braking and turning |

| Key Factors | Asphalt mix stiffness, aggregate interlock, binder properties | Surface texture, aggregate type and size, microtexture and macrotexture |

| Testing Methods | Wheel tracking test, Hamburg wheel tracking test | British Pendulum Test (BPT), Dynamic Friction Tester (DFT) |

| Performance Indicator | Lower rut depth under traffic loading | Higher friction coefficient between tire and pavement |

| Trade-offs | High stiffness may reduce skid resistance if surface texture is compromised | Enhanced skid resistance can cause faster wear, impacting rutting resistance |

Introduction to Asphalt Pavement Performance

Rutting resistance and skid resistance are critical performance indicators of asphalt pavement durability and safety. Rutting resistance measures the pavement's ability to withstand permanent deformation under repeated traffic loading, preventing surface depressions. Skid resistance evaluates the frictional properties of the pavement surface, directly influencing vehicle traction and road safety during various weather conditions.

Defining Rutting Resistance in Asphalt Materials

Rutting resistance in asphalt materials refers to the pavement's ability to withstand permanent deformation under repeated traffic loading, especially from heavy vehicles. It is primarily influenced by the asphalt binder properties, aggregate gradation, and compaction levels, which together impact the mixture's stability and load distribution. Effective rutting resistance enhances pavement durability and reduces maintenance costs by preventing surface depressions that compromise ride quality and safety.

Understanding Skid Resistance in Road Surfaces

Skid resistance in asphalt road surfaces is crucial for vehicle safety, as it directly affects tire grip under wet or slippery conditions. It is influenced by aggregate texture, binder type, and surface roughness, which collectively determine the pavement's ability to prevent skidding. While rutting resistance measures deformation under load, effective skid resistance ensures better traction and reduces accident risks on asphalt pavements.

Material Properties Affecting Rutting Resistance

Material properties such as aggregate hardness, asphalt binder stiffness, and mixture density play a crucial role in enhancing rutting resistance in asphalt pavements. Higher aggregate angularity and grade of binder contribute to improved deformation resistance under repeated traffic loading. Optimizing these properties helps maintain pavement structural integrity while balancing skid resistance performance for safer road surfaces.

Surface Texture and Its Role in Skid Resistance

Surface texture directly influences skid resistance by enhancing tire-pavement interaction, where micro and macrotextures provide crucial grip to prevent vehicle slippage. While rutting resistance primarily depends on asphalt mixture stiffness and deformation capacity under load, skid resistance is significantly affected by the preservation of surface texture against wear and polishing. Optimizing surface texture ensures sustained friction levels, contributing to safer road conditions even as structural performance like rutting resistance varies.

Trade-offs Between Rutting and Skid Resistance

Balancing rutting resistance and skid resistance in asphalt pavement involves trade-offs where materials enhancing one property may compromise the other. High rutting resistance often relies on stiffer binders and denser gradations, which can reduce surface texture and decrease skid resistance. Optimizing aggregate selection and mixture design is critical to achieving a pavement surface that adequately resists deformation while maintaining sufficient friction for vehicle safety.

Asphalt Mix Design Strategies for Dual Performance

Asphalt mix design strategies prioritize balancing rutting resistance and skid resistance by optimizing aggregate gradation and binder selection to enhance durability and safety. Incorporating polymer-modified binders and higher-quality aggregates improves the mix's ability to resist permanent deformation while maintaining a textured surface for adequate friction. Advanced performance testing and precise control of void content ensure that the asphalt achieves both structural stability and optimal skid resistance under varying traffic loads and environmental conditions.

Innovative Additives to Enhance Resistance Properties

Innovative additives such as polymer-modified binders and nanomaterials significantly enhance rutting resistance and skid resistance in asphalt pavements. These additives improve the binder's elasticity and adhesion, reducing permanent deformation under heavy traffic loads while maintaining surface friction for safety. Optimizing additive concentrations ensures a balanced performance, making roads safer and longer-lasting in diverse environmental conditions.

Field Testing: Measuring Rutting and Skid Resistance

Field testing for rutting resistance involves using devices like the Straightedge and the Automated Road Analyzer to measure pavement deformation under traffic loads, ensuring surface durability. Skid resistance is assessed through portable friction testers such as the British Pendulum Tester or the Dynamic Friction Tester, which gauge pavement texture and friction to enhance vehicle safety. Accurate field measurements of both rutting and skid resistance are critical for maintaining pavement performance and reducing accident risks.

Future Trends in Asphalt Pavement Optimization

Future trends in asphalt pavement optimization emphasize balancing rutting resistance and skid resistance through advanced polymer-modified binders and nanomaterials. Innovations in mixture design leverage recycled materials and nano-additives to enhance durability while maintaining surface friction essential for safety. Smart asphalt technologies incorporating sensors enable real-time monitoring of pavement performance, optimizing maintenance strategies to extend lifespan and improve safety outcomes.

Rutting Resistance vs Skid Resistance Infographic

materialdif.com

materialdif.com