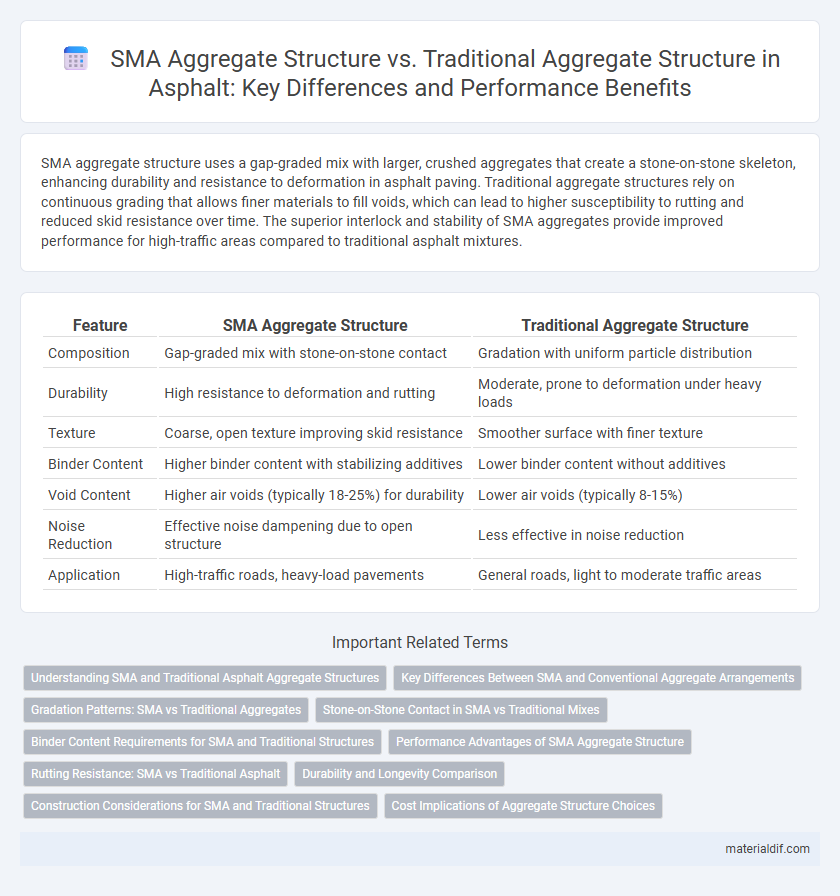

SMA aggregate structure uses a gap-graded mix with larger, crushed aggregates that create a stone-on-stone skeleton, enhancing durability and resistance to deformation in asphalt paving. Traditional aggregate structures rely on continuous grading that allows finer materials to fill voids, which can lead to higher susceptibility to rutting and reduced skid resistance over time. The superior interlock and stability of SMA aggregates provide improved performance for high-traffic areas compared to traditional asphalt mixtures.

Table of Comparison

| Feature | SMA Aggregate Structure | Traditional Aggregate Structure |

|---|---|---|

| Composition | Gap-graded mix with stone-on-stone contact | Gradation with uniform particle distribution |

| Durability | High resistance to deformation and rutting | Moderate, prone to deformation under heavy loads |

| Texture | Coarse, open texture improving skid resistance | Smoother surface with finer texture |

| Binder Content | Higher binder content with stabilizing additives | Lower binder content without additives |

| Void Content | Higher air voids (typically 18-25%) for durability | Lower air voids (typically 8-15%) |

| Noise Reduction | Effective noise dampening due to open structure | Less effective in noise reduction |

| Application | High-traffic roads, heavy-load pavements | General roads, light to moderate traffic areas |

Understanding SMA and Traditional Asphalt Aggregate Structures

Stone Mastic Asphalt (SMA) aggregate structure consists of a coarse, gap-graded skeleton with high coarse aggregate content, providing enhanced stone-on-stone contact for superior rut resistance and durability. Traditional asphalt aggregate structures feature a dense-graded mixture with a more continuous range of particle sizes, resulting in a more homogeneous texture but lower resistance to deformation under heavy loads. Understanding the distinct gradation and aggregate interlock mechanisms in SMA versus traditional asphalt is essential for optimizing pavement performance and longevity.

Key Differences Between SMA and Conventional Aggregate Arrangements

Stone Mastic Asphalt (SMA) features a gap-graded aggregate structure with a high content of coarse aggregates, providing a strong, stone-on-stone skeleton that enhances rut resistance and durability, unlike traditional dense-graded asphalt which has a continuous gradation of particle sizes. SMA uses increased binder content and fibers to stabilize the mastic and prevent binder drain-down, whereas conventional mixes rely on uniform aggregate gradation and lower binder content for cohesion. The key difference lies in SMA's focus on maximizing coarse aggregate contact and mastic stability to improve load-bearing capacity and pavement lifespan compared to traditional asphalt's emphasis on uniform gradation for ease of compaction.

Gradation Patterns: SMA vs Traditional Aggregates

Stone Matrix Asphalt (SMA) features a gap-graded aggregate structure with coarse aggregates forming a strong skeleton, ensuring high load resistance and durability. Traditional asphalt mixtures utilize a continuous gradation pattern, promoting better workability but lower deformation resistance. The optimized gradation in SMA enhances rutting resistance by maximizing coarse angular particles and minimizing fine aggregates.

Stone-on-Stone Contact in SMA vs Traditional Mixes

Stone-on-stone contact in Stone Matrix Asphalt (SMA) aggregate structure creates a robust skeleton that enhances load distribution and durability, significantly reducing deformation under heavy traffic loads. In contrast, traditional asphalt mixes rely more on fine aggregate and asphalt binder to support the structure, resulting in less direct aggregate interlock and increased susceptibility to rutting. SMA's optimized aggregate gradation promotes higher stone-on-stone interaction, improving resistance to cracking and rutting compared to conventional asphalt mixtures.

Binder Content Requirements for SMA and Traditional Structures

Stone Mastic Asphalt (SMA) requires a higher binder content, typically 6-7%, compared to traditional dense-graded asphalt mixtures which generally use 4-6% binder. This increased binder content in SMA enhances durability, improves resistance to rutting, and provides a more flexible pavement structure by effectively coating the coarse aggregate skeleton. Traditional aggregate structures rely on lower binder content as their finer gradation compacts the aggregate tightly, reducing the need for excess binder to fill voids.

Performance Advantages of SMA Aggregate Structure

Stone Mastic Asphalt (SMA) aggregate structure incorporates a higher percentage of coarse aggregates and a strong skeleton interlock that enhances load distribution and rutting resistance compared to traditional aggregate structures. The dense framework of SMA improves durability by reducing binder draindown and increasing resistance to deformation under heavy traffic loads. This optimized aggregate gradation provides superior skid resistance and longer service life in high-stress pavement applications.

Rutting Resistance: SMA vs Traditional Asphalt

Stone Mastic Asphalt (SMA) features a coarse aggregate skeleton with a high concentration of coarse aggregates, enhancing interlock and load distribution, which significantly improves rutting resistance compared to traditional asphalt mixtures. Traditional asphalt typically relies on a more uniform aggregate gradation with higher fine content, making it more susceptible to deformation under heavy traffic loads. The enhanced rutting resistance of SMA is primarily due to its gap-graded structure that reduces binder drain-down and maintains structural integrity under shear stress.

Durability and Longevity Comparison

Stone Matrix Asphalt (SMA) aggregate structure features a coarse, gap-graded mix with a high binder content and fibers, providing enhanced durability and resistance to rutting compared to traditional dense-graded aggregate structures. The open-graded nature of SMA allows better stress distribution and crack resistance, significantly extending pavement longevity under heavy traffic and harsh environmental conditions. Traditional aggregate structures, while cost-effective, often exhibit lower resistance to deformation and moisture damage, leading to reduced lifespan and increased maintenance needs.

Construction Considerations for SMA and Traditional Structures

SMA (Stone Mastic Asphalt) features a gap-graded aggregate structure designed to provide high stone-on-stone contact, offering superior rut resistance and durability compared to traditional dense-graded asphalt mixtures. Construction considerations for SMA require precise control of binder content and use of fibers or stabilizers to prevent binder draindown, along with specialized compaction techniques to achieve optimal density without compromising its open-graded matrix. In contrast, traditional asphalt construction benefits from more flexible aggregate gradation, simpler mixing and compaction processes, and lower sensitivity to binder content variation, but it may lack the enhanced performance characteristics inherent in SMA's aggregate framework.

Cost Implications of Aggregate Structure Choices

SMA aggregate structure, characterized by a gap-graded mix with higher coarse aggregate content, generally leads to increased material costs compared to traditional dense-graded aggregate structures due to the use of premium-quality aggregates and polymer-modified binders. However, SMA's enhanced durability and resistance to rutting and cracking can reduce long-term maintenance expenses, offsetting initial investment through extended pavement life. Traditional aggregate structures benefit from lower upfront costs but may incur higher repair and rehabilitation expenditures over time due to less robust performance under heavy traffic conditions.

SMA Aggregate Structure vs Traditional Aggregate Structure Infographic

materialdif.com

materialdif.com