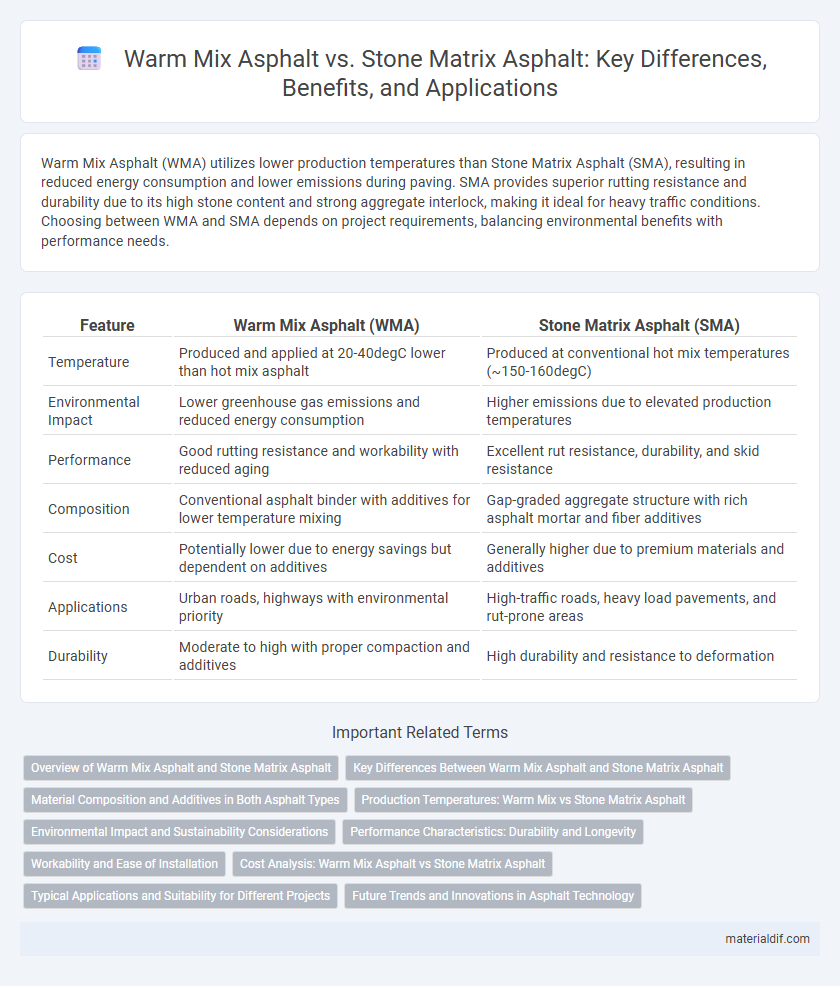

Warm Mix Asphalt (WMA) utilizes lower production temperatures than Stone Matrix Asphalt (SMA), resulting in reduced energy consumption and lower emissions during paving. SMA provides superior rutting resistance and durability due to its high stone content and strong aggregate interlock, making it ideal for heavy traffic conditions. Choosing between WMA and SMA depends on project requirements, balancing environmental benefits with performance needs.

Table of Comparison

| Feature | Warm Mix Asphalt (WMA) | Stone Matrix Asphalt (SMA) |

|---|---|---|

| Temperature | Produced and applied at 20-40degC lower than hot mix asphalt | Produced at conventional hot mix temperatures (~150-160degC) |

| Environmental Impact | Lower greenhouse gas emissions and reduced energy consumption | Higher emissions due to elevated production temperatures |

| Performance | Good rutting resistance and workability with reduced aging | Excellent rut resistance, durability, and skid resistance |

| Composition | Conventional asphalt binder with additives for lower temperature mixing | Gap-graded aggregate structure with rich asphalt mortar and fiber additives |

| Cost | Potentially lower due to energy savings but dependent on additives | Generally higher due to premium materials and additives |

| Applications | Urban roads, highways with environmental priority | High-traffic roads, heavy load pavements, and rut-prone areas |

| Durability | Moderate to high with proper compaction and additives | High durability and resistance to deformation |

Overview of Warm Mix Asphalt and Stone Matrix Asphalt

Warm Mix Asphalt (WMA) incorporates additives or processes to lower production temperatures by 20-40degC, reducing energy consumption and emissions while maintaining workability and performance. Stone Matrix Asphalt (SMA) features a gap-graded aggregate structure with a high coarse aggregate content and a rich mortar binder, providing exceptional rut resistance and durability under heavy traffic loads. Both asphalt mixtures offer durable pavement solutions but differ in production methods, temperature requirements, and structural properties specific to road performance.

Key Differences Between Warm Mix Asphalt and Stone Matrix Asphalt

Warm Mix Asphalt (WMA) is produced at lower temperatures, reducing energy consumption and emissions, while Stone Matrix Asphalt (SMA) features a gap-graded aggregate structure with high coarse aggregate content for enhanced rut resistance and durability. WMA offers improved workability and compaction at cooler temperatures, making it environmentally friendly, whereas SMA provides superior performance under heavy traffic due to its stone-on-stone contact and polymer-modified binder. The primary differences lie in production temperature, mixture design, and performance characteristics tailored for specific paving requirements.

Material Composition and Additives in Both Asphalt Types

Warm Mix Asphalt (WMA) incorporates additives such as waxes, organic materials, or chemical agents to lower the mixing and compaction temperatures, enhancing workability and reducing emissions, while its aggregate composition remains similar to traditional asphalt mixtures. Stone Matrix Asphalt (SMA) features a gap-graded aggregate structure with a higher percentage of coarse aggregates and fibers, often cellulose or mineral, to improve rutting resistance and durability. Both asphalt types use a bituminous binder, but the inclusion of specialized additives in WMA facilitates lower production temperatures, contrasting with SMA's reliance on aggregate gradation and reinforcing fibers for performance.

Production Temperatures: Warm Mix vs Stone Matrix Asphalt

Warm Mix Asphalt (WMA) is produced at temperatures typically ranging from 100degC to 140degC, significantly lower than Stone Matrix Asphalt (SMA), which requires production temperatures around 140degC to 160degC. The reduced production temperatures of WMA minimize energy consumption and greenhouse gas emissions while maintaining workability and compaction efficiency. Stone Matrix Asphalt's higher temperature range supports its stone-on-stone skeleton structure, providing enhanced rutting resistance and durability.

Environmental Impact and Sustainability Considerations

Warm Mix Asphalt (WMA) significantly reduces energy consumption and greenhouse gas emissions compared to traditional Hot Mix Asphalt due to its lower production temperature, enhancing sustainability in road construction. Stone Matrix Asphalt (SMA), while durable and offering superior rut resistance, often requires higher binder content and elevated production temperatures, leading to increased environmental impact. Choosing WMA supports eco-friendly practices by minimizing carbon footprint and improving worker safety through reduced fumes, whereas SMA emphasizes longevity and performance, contributing to lifecycle sustainability through extended pavement service life.

Performance Characteristics: Durability and Longevity

Warm Mix Asphalt (WMA) offers improved workability and reduced emissions while maintaining adequate durability for moderate traffic conditions. Stone Matrix Asphalt (SMA) is engineered for high durability and exceptional rut resistance, providing superior longevity under heavy traffic loads due to its rich binder content and stone-on-stone contact. The choice between WMA and SMA significantly impacts pavement lifespan, with SMA typically delivering enhanced performance in high-stress environments.

Workability and Ease of Installation

Warm Mix Asphalt (WMA) offers superior workability due to its lower mixing and compaction temperatures, which reduce energy consumption and allow for extended hauling distances without compromising material quality. Stone Matrix Asphalt (SMA) is characterized by its open-graded aggregate structure, providing enhanced rut resistance but requiring more precise handling and installation techniques to achieve optimal compaction. While WMA facilitates easier placement and improved worker safety through lower temperatures, SMA demands skilled installation to maintain its durability and resistance properties.

Cost Analysis: Warm Mix Asphalt vs Stone Matrix Asphalt

Warm Mix Asphalt (WMA) generally offers lower initial production and transportation costs due to reduced mixing temperatures, leading to significant energy savings compared to Stone Matrix Asphalt (SMA). SMA typically incurs higher material costs because of its rich binder content and coarse aggregate structure, though it often provides longer pavement life and lower maintenance expenses over time. The cost analysis between WMA and SMA should consider both upfront expenses and lifecycle costs to determine the most economically viable option for specific paving projects.

Typical Applications and Suitability for Different Projects

Warm Mix Asphalt (WMA) is ideal for urban roadways, parking lots, and rehabilitation projects due to its lower production temperatures and reduced emissions, enhancing workability in cooler climates. Stone Matrix Asphalt (SMA) excels in high-traffic highways and heavy-load-bearing surfaces thanks to its durable, rut-resistant design and stone-on-stone skeleton structure. Choosing between WMA and SMA depends on factors such as traffic volume, environmental conditions, and project duration requirements.

Future Trends and Innovations in Asphalt Technology

Warm Mix Asphalt (WMA) and Stone Matrix Asphalt (SMA) are evolving with innovations that emphasize sustainability and performance in road construction. Advances in WMA technology focus on reducing production temperatures and emissions through additives and foaming techniques, promoting energy savings and environmental benefits. SMA enhancements aim to improve durability and resistance to rutting by incorporating polymer-modified binders and optimized aggregate gradations, addressing growing infrastructure demands.

Warm Mix Asphalt vs Stone Matrix Asphalt Infographic

materialdif.com

materialdif.com