Cold mix asphalt is ideal for low-traffic areas and quick repairs due to its ease of application at lower temperatures, reducing energy consumption and emissions. Hot mix asphalt offers superior durability and strength, making it suitable for high-traffic roads and heavy-load surfaces with better compaction and longer lifespan. Choosing between cold mix and hot mix asphalt depends on project requirements, budget, and environmental conditions.

Table of Comparison

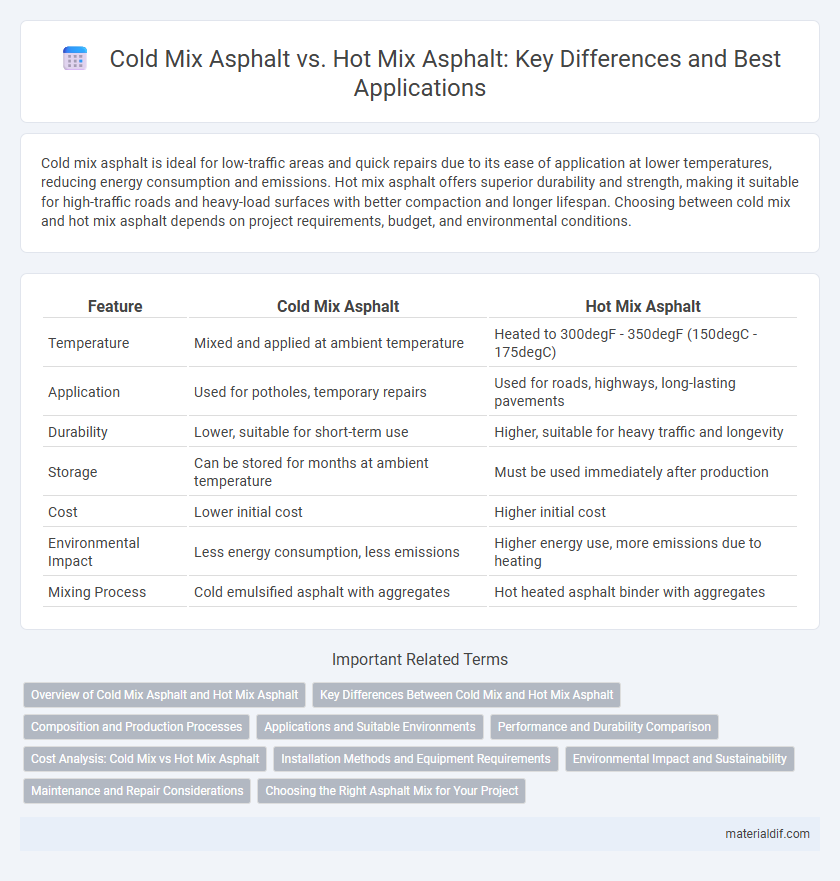

| Feature | Cold Mix Asphalt | Hot Mix Asphalt |

|---|---|---|

| Temperature | Mixed and applied at ambient temperature | Heated to 300degF - 350degF (150degC - 175degC) |

| Application | Used for potholes, temporary repairs | Used for roads, highways, long-lasting pavements |

| Durability | Lower, suitable for short-term use | Higher, suitable for heavy traffic and longevity |

| Storage | Can be stored for months at ambient temperature | Must be used immediately after production |

| Cost | Lower initial cost | Higher initial cost |

| Environmental Impact | Less energy consumption, less emissions | Higher energy use, more emissions due to heating |

| Mixing Process | Cold emulsified asphalt with aggregates | Hot heated asphalt binder with aggregates |

Overview of Cold Mix Asphalt and Hot Mix Asphalt

Cold Mix Asphalt consists of aggregates mixed with liquid asphalt at ambient temperatures, making it suitable for low-traffic roads and temporary repairs due to its ease of application and longer storage life. Hot Mix Asphalt is prepared by heating aggregates and asphalt binder to high temperatures, producing a denser, more durable pavement ideal for high-traffic areas and long-term road surfaces. Both types differ significantly in production methods, performance characteristics, and ideal usage scenarios.

Key Differences Between Cold Mix and Hot Mix Asphalt

Cold Mix Asphalt is produced at ambient temperatures and mainly used for low-traffic roads and temporary repairs, offering easier application and quicker curing times. Hot Mix Asphalt is manufactured at temperatures between 300degF and 350degF, providing superior durability, strength, and resistance to heavy traffic and extreme weather conditions. The key differences lie in production temperature, application methods, performance under stress, and longevity, making Hot Mix Asphalt preferable for major pavements and Cold Mix suitable for maintenance and light-duty use.

Composition and Production Processes

Cold mix asphalt consists of unheated aggregate coated with bitumen emulsion, allowing it to be produced at ambient temperatures and enabling quicker application without heavy machinery. Hot mix asphalt is created by heating aggregate and bitumen to temperatures between 300-350degF, resulting in a viscous mixture that requires specialized plants and equipment for thorough blending and compaction. The contrasting composition and production processes impact their performance, with cold mix favored for temporary repairs and hot mix preferred for durable, high-traffic road surfaces.

Applications and Suitable Environments

Cold Mix Asphalt is ideal for low-traffic roads, temporary patches, and rural areas due to its ease of application at ambient temperatures and quick curing time. Hot Mix Asphalt provides superior durability and smoothness, making it suitable for highways, urban roads, and heavy-traffic environments where high load-bearing capacity and long-lasting performance are critical. The choice between cold and hot mix asphalt depends on project scale, budget constraints, climate conditions, and expected traffic volume.

Performance and Durability Comparison

Cold mix asphalt exhibits lower strength and durability compared to hot mix asphalt, making it more suitable for temporary repairs or low-traffic areas. Hot mix asphalt offers superior performance in terms of load-bearing capacity, resistance to deformation, and longevity due to its higher compaction and binder quality. The thermal properties of hot mix asphalt contribute to better moisture resistance and extended pavement life, which cold mix formulations cannot fully match.

Cost Analysis: Cold Mix vs Hot Mix Asphalt

Cold Mix Asphalt typically incurs lower initial costs due to its simplified production process and the absence of heating, making it a cost-effective solution for small-scale repairs and low-traffic roads. Hot Mix Asphalt involves higher energy consumption and specialized equipment, resulting in greater upfront expenses but offers superior durability and longevity, which can reduce long-term maintenance costs. Evaluating the total cost of ownership, including installation, lifespan, and maintenance, is crucial to determine the most economical option for specific project requirements.

Installation Methods and Equipment Requirements

Cold mix asphalt requires simpler installation methods, as it can be applied at ambient temperatures using standard paving equipment and hand tools, making it ideal for small repairs and low-traffic areas. Hot mix asphalt demands specialized equipment, including asphalt drum mixers or batch plants to heat and dry the aggregate and bitumen, and heavy machinery like pavers and rollers to ensure proper compaction at high temperatures. The energy-intensive nature and precise temperature control of hot mix asphalt installation enhance durability but necessitate complex logistics and equipment maintenance.

Environmental Impact and Sustainability

Cold Mix Asphalt significantly reduces energy consumption and greenhouse gas emissions compared to Hot Mix Asphalt by eliminating the need for high-temperature heating during production. Its lower production temperatures enable the use of reclaimed asphalt pavement (RAP) and recycled materials, promoting resource conservation and reducing landfill waste. Although Hot Mix Asphalt offers greater durability for heavy traffic, Cold Mix Asphalt advances environmental sustainability through decreased carbon footprint and enhanced recyclability, making it ideal for maintenance and low-traffic applications.

Maintenance and Repair Considerations

Cold mix asphalt offers a cost-effective and quick solution for emergency repairs and small patching jobs, allowing for application in lower temperatures without specialized equipment. Hot mix asphalt provides superior durability and longevity, making it ideal for large-scale maintenance projects and resurfacing where long-term performance is critical. Selecting between cold mix and hot mix asphalt depends on factors like project size, climate conditions, and the expected lifespan of the repair.

Choosing the Right Asphalt Mix for Your Project

Cold mix asphalt offers advantages for small-scale repairs and low-traffic areas due to its ease of application and cost-effectiveness, while hot mix asphalt provides superior durability and strength, ideal for high-traffic roads and large-scale projects. Selecting the right asphalt mix depends on project size, traffic load, climate conditions, and budget constraints to ensure longevity and performance. Engineers often favor hot mix asphalt for its enhanced resistance to heavy loads and weathering, whereas cold mix asphalt suits temporary fixes and less demanding environments.

Cold Mix Asphalt vs Hot Mix Asphalt Infographic

materialdif.com

materialdif.com