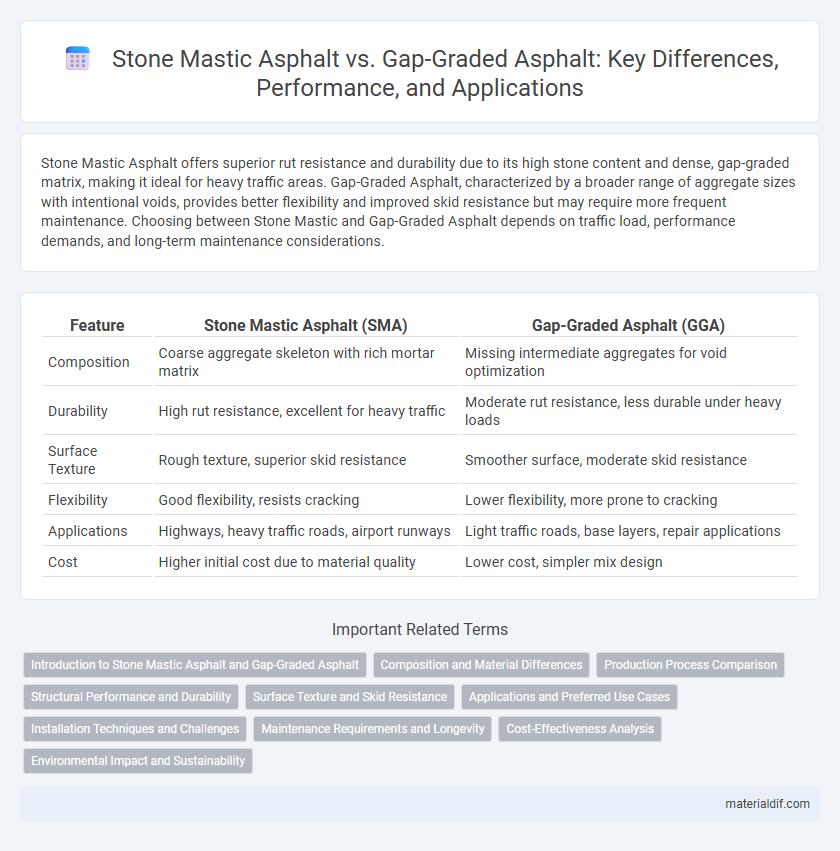

Stone Mastic Asphalt offers superior rut resistance and durability due to its high stone content and dense, gap-graded matrix, making it ideal for heavy traffic areas. Gap-Graded Asphalt, characterized by a broader range of aggregate sizes with intentional voids, provides better flexibility and improved skid resistance but may require more frequent maintenance. Choosing between Stone Mastic and Gap-Graded Asphalt depends on traffic load, performance demands, and long-term maintenance considerations.

Table of Comparison

| Feature | Stone Mastic Asphalt (SMA) | Gap-Graded Asphalt (GGA) |

|---|---|---|

| Composition | Coarse aggregate skeleton with rich mortar matrix | Missing intermediate aggregates for void optimization |

| Durability | High rut resistance, excellent for heavy traffic | Moderate rut resistance, less durable under heavy loads |

| Surface Texture | Rough texture, superior skid resistance | Smoother surface, moderate skid resistance |

| Flexibility | Good flexibility, resists cracking | Lower flexibility, more prone to cracking |

| Applications | Highways, heavy traffic roads, airport runways | Light traffic roads, base layers, repair applications |

| Cost | Higher initial cost due to material quality | Lower cost, simpler mix design |

Introduction to Stone Mastic Asphalt and Gap-Graded Asphalt

Stone Mastic Asphalt (SMA) is a durable pavement mixture characterized by a high coarse aggregate content and a rich mortar binder, designed to provide enhanced rut resistance and long service life. Gap-Graded Asphalt features a mix of aggregate sizes with missing intermediate sizes, offering improved flexibility and deformation resistance in various traffic conditions. Both asphalt types optimize structural performance and surface texture, catering to specific road construction requirements.

Composition and Material Differences

Stone Mastic Asphalt (SMA) features a high binder content combined with a rich mortar of bitumen, filler, and additives, providing a durable and rut-resistant surface. Gap-Graded Asphalt (GGA) has a particle size distribution with a gap or missing intermediate sizes, which enhances voids and allows for better compaction and flexibility. SMA's coarse aggregate skeleton ensures stone-on-stone contact for strength, while GGA's varied particle sizes promote flexibility and improved deformation resistance.

Production Process Comparison

Stone Mastic Asphalt (SMA) production involves a higher binder content and requires incorporating fibers to enhance mixture stability, demanding precise temperature control during mixing to prevent binder drainage. Gap-Graded Asphalt (GGA) utilizes a more open aggregate gradation, allowing for lower binder content and faster cooling, which simplifies mixing and compaction processes. The production of SMA is generally more complex and energy-intensive compared to GGA, due to the need for added stabilizers and controlled mixing conditions.

Structural Performance and Durability

Stone Mastic Asphalt (SMA) offers superior structural performance due to its high coarse aggregate content and rich mortar binder, providing enhanced rut resistance and load-bearing capacity compared to Gap-Graded Asphalt. Gap-Graded Asphalt features a deliberately missing intermediate aggregate size, improving interlock and durability but often resulting in lower deformation resistance under heavy traffic loads. The durability of SMA is particularly notable in high-stress environments, maintaining surface texture and reducing cracking over time, whereas Gap-Graded Asphalt may require more frequent maintenance to address fatigue and rutting issues.

Surface Texture and Skid Resistance

Stone Mastic Asphalt (SMA) features a coarse surface texture with a high volume of coarse aggregates, resulting in excellent skid resistance and durability under heavy traffic. Gap-Graded Asphalt has a less uniform surface texture due to its broader aggregate size distribution, which can lead to lower skid resistance compared to SMA. The dense, coarse surface of SMA provides superior water drainage and friction, making it preferable for high-speed roadways requiring enhanced safety.

Applications and Preferred Use Cases

Stone Mastic Asphalt (SMA) is preferred for high-traffic highways and urban roads due to its superior rut resistance and durability under heavy loads. Gap-Graded Asphalt excels in applications requiring enhanced skid resistance and flexibility, making it ideal for airport runways and areas with frequent temperature fluctuations. SMA's dense structure optimizes load distribution, while Gap-Graded Asphalt provides better noise reduction and surface texture for safety-critical environments.

Installation Techniques and Challenges

Stone Mastic Asphalt (SMA) requires specialized installation techniques involving a higher binder content and the use of cellulose fibers to prevent binder drainage, making compaction more challenging but resulting in superior rut resistance. Gap-Graded Asphalt demands careful aggregate selection to achieve the desired void structure, with a focus on precise temperature control during mixing and paving to avoid segregation and ensure durability. Both materials necessitate experienced crews and stringent quality control measures to address their unique challenges and optimize pavement performance.

Maintenance Requirements and Longevity

Stone Mastic Asphalt (SMA) exhibits superior durability and lower maintenance requirements due to its high stone content and strong binder matrix, which resist rutting and deformation effectively. Gap-Graded Asphalt tends to require more frequent maintenance as its aggregate gradation allows for easier deformation and susceptibility to moisture damage. SMA's enhanced longevity and performance in heavy traffic conditions make it a preferred choice for long-term pavement sustainability.

Cost-Effectiveness Analysis

Stone Mastic Asphalt (SMA) offers higher initial costs due to premium binder and additives but provides superior durability and reduced maintenance expenses over time, leading to better long-term cost-effectiveness compared to Gap-Graded Asphalt (GGA). Gap-Graded Asphalt typically has lower upfront costs but may incur higher lifecycle expenses due to increased rutting and cracking potential, requiring more frequent repairs. Evaluating total ownership costs, SMA's enhanced performance in heavy traffic conditions makes it a more economical choice in infrastructure projects prioritizing longevity and reduced maintenance budgets.

Environmental Impact and Sustainability

Stone Mastic Asphalt (SMA) offers superior durability and reduced maintenance frequency, leading to lower life-cycle environmental impacts compared to Gap-Graded Asphalt (GGA). SMA's high binder content and optimized aggregate interlock result in enhanced resistance to rutting and cracking, minimizing the need for frequent repairs and conserving raw materials. Gap-Graded Asphalt may require more frequent resurfacing, increasing resource consumption and carbon emissions over time, which impacts its sustainability profile negatively.

Stone Mastic Asphalt vs Gap-Graded Asphalt Infographic

materialdif.com

materialdif.com