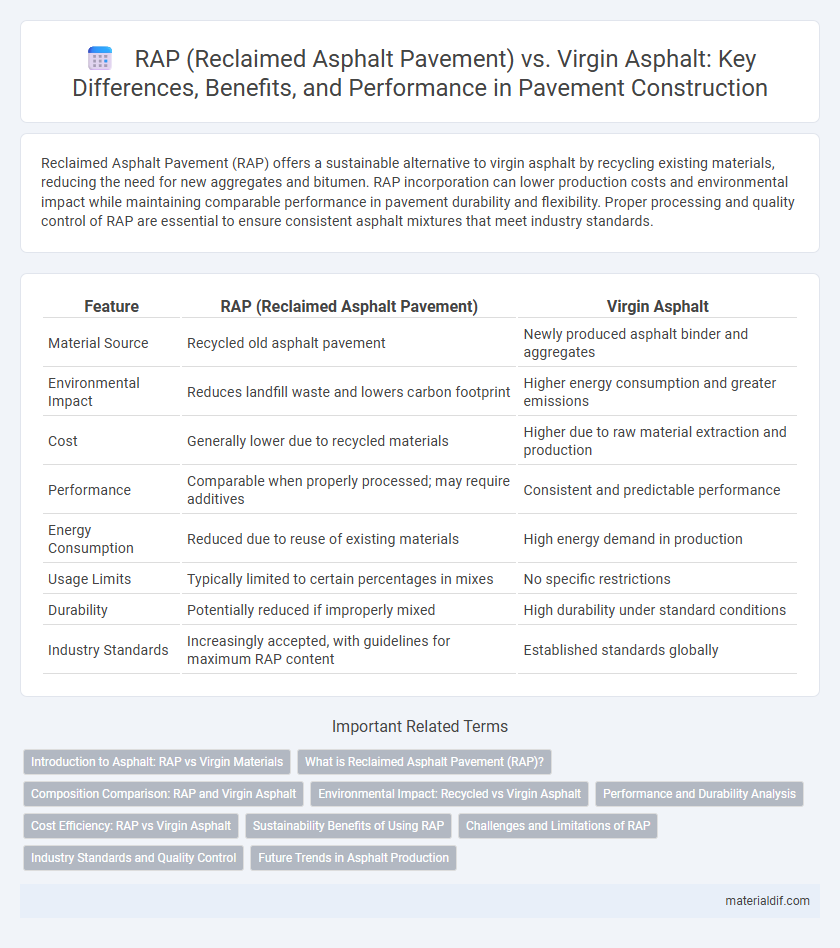

Reclaimed Asphalt Pavement (RAP) offers a sustainable alternative to virgin asphalt by recycling existing materials, reducing the need for new aggregates and bitumen. RAP incorporation can lower production costs and environmental impact while maintaining comparable performance in pavement durability and flexibility. Proper processing and quality control of RAP are essential to ensure consistent asphalt mixtures that meet industry standards.

Table of Comparison

| Feature | RAP (Reclaimed Asphalt Pavement) | Virgin Asphalt |

|---|---|---|

| Material Source | Recycled old asphalt pavement | Newly produced asphalt binder and aggregates |

| Environmental Impact | Reduces landfill waste and lowers carbon footprint | Higher energy consumption and greater emissions |

| Cost | Generally lower due to recycled materials | Higher due to raw material extraction and production |

| Performance | Comparable when properly processed; may require additives | Consistent and predictable performance |

| Energy Consumption | Reduced due to reuse of existing materials | High energy demand in production |

| Usage Limits | Typically limited to certain percentages in mixes | No specific restrictions |

| Durability | Potentially reduced if improperly mixed | High durability under standard conditions |

| Industry Standards | Increasingly accepted, with guidelines for maximum RAP content | Established standards globally |

Introduction to Asphalt: RAP vs Virgin Materials

Reclaimed Asphalt Pavement (RAP) consists of processed old asphalt materials, offering a sustainable alternative to virgin asphalt by reducing the demand for new aggregates and bitumen. Virgin asphalt relies on freshly mined aggregates bound with new bitumen, providing consistent performance but at higher environmental and economic costs. Integrating RAP in asphalt mixtures enhances resource efficiency, lowers greenhouse gas emissions, and often improves cost-effectiveness while maintaining comparable durability and structural integrity.

What is Reclaimed Asphalt Pavement (RAP)?

Reclaimed Asphalt Pavement (RAP) consists of milling or removal of existing asphalt pavement which is then recycled and reused in new asphalt mixtures. RAP contains a blend of aged asphalt binder and aggregates, offering both economic and environmental advantages by reducing the need for virgin materials. Using RAP in asphalt production helps lower greenhouse gas emissions, conserve natural resources, and maintain pavement performance standards.

Composition Comparison: RAP and Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) consists of aged binder and aggregates recovered from milled or reconstructed pavement layers, containing a higher proportion of oxidized asphalt binder and varying aggregate quality compared to virgin asphalt. Virgin asphalt typically features fresh, consistent aggregates and unoxidized petroleum-based binder, ensuring uniformity in chemical composition and performance. The integration of RAP alters the blend's binder stiffness and aggregate gradation, necessitating careful proportioning to achieve desired mechanical properties in asphalt mixtures.

Environmental Impact: Recycled vs Virgin Asphalt

RAP (Reclaimed Asphalt Pavement) significantly reduces the environmental impact by lowering the demand for virgin aggregates and bitumen, resulting in decreased energy consumption and greenhouse gas emissions during production. Incorporating RAP minimizes landfill waste and conserves natural resources, aligning with sustainable pavement construction practices. Virgin asphalt production requires extensive extraction and processing, contributing to higher carbon footprints compared to recycled asphalt mixtures.

Performance and Durability Analysis

Reclaimed Asphalt Pavement (RAP) demonstrates comparable or superior performance in terms of rutting resistance and stiffness when blended properly with virgin asphalt, enhancing durability in pavement applications. Studies reveal that incorporating RAP reduces thermal cracking and aging susceptibility, extending service life compared to purely virgin asphalt mixes. Optimal RAP content and rejuvenator use are critical to maintaining mechanical properties and achieving sustainable, long-lasting pavement performance.

Cost Efficiency: RAP vs Virgin Asphalt

Reclaimed Asphalt Pavement (RAP) significantly reduces material costs compared to virgin asphalt by recycling existing pavement materials, lowering the need for new aggregates and bitumen. The use of RAP also decreases transportation and production expenses, contributing to overall project cost efficiency. Despite slightly higher processing costs to ensure quality, RAP provides substantial savings in asphalt paving projects versus using 100% virgin asphalt.

Sustainability Benefits of Using RAP

Reclaimed Asphalt Pavement (RAP) significantly reduces the demand for virgin asphalt, conserving natural bitumen resources and lowering greenhouse gas emissions associated with extraction and processing. Utilizing RAP decreases landfill waste by recycling old pavement materials, promoting circular economy principles in road construction. The energy savings from processing RAP compared to virgin asphalt contribute to a sustainable infrastructure with reduced environmental impact.

Challenges and Limitations of RAP

Reclaimed Asphalt Pavement (RAP) presents challenges such as potential variability in material quality, which can affect the consistency and performance of the final asphalt mix. High RAP content may lead to reduced workability and increased stiffness, raising the risk of cracking under traffic loads. Limitations include the need for precise mix design adjustments and careful quality control to maintain durability and compliance with pavement standards.

Industry Standards and Quality Control

RAP (Reclaimed Asphalt Pavement) integration into mixes must comply with strict industry standards like ASTM D6521 and AASHTO M 320 to ensure performance equivalency with virgin asphalt. Quality control measures emphasize precise RAP content limits, aggregate gradation, and binder properties to maintain durability and structural integrity. Continuous testing including moisture content, asphalt binder quality, and volumetric properties governs the consistent production of high-quality asphalt blends meeting DOT specifications.

Future Trends in Asphalt Production

Future trends in asphalt production emphasize increasing the use of Reclaimed Asphalt Pavement (RAP) to enhance sustainability and reduce reliance on virgin asphalt. Innovations in processing technologies improve RAP material quality, enabling higher incorporation rates without compromising pavement performance. Growing regulatory support and environmental mandates drive the industry towards more circular asphalt economy models, promoting resource efficiency and lower carbon footprints.

RAP (Reclaimed Asphalt Pavement) vs Virgin asphalt Infographic

materialdif.com

materialdif.com