Superpave Asphalt offers enhanced performance by using advanced testing methods to optimize aggregate gradation and binder properties, resulting in superior resistance to rutting and cracking under diverse climate conditions. Marshall Mix Asphalt relies on a volumetric mix design approach that focuses on stability and voids, providing reliable strength but less adaptability to varying traffic loads and temperatures. Choosing Superpave Asphalt generally leads to longer-lasting pavements with improved durability compared to the traditional Marshall Mix Asphalt.

Table of Comparison

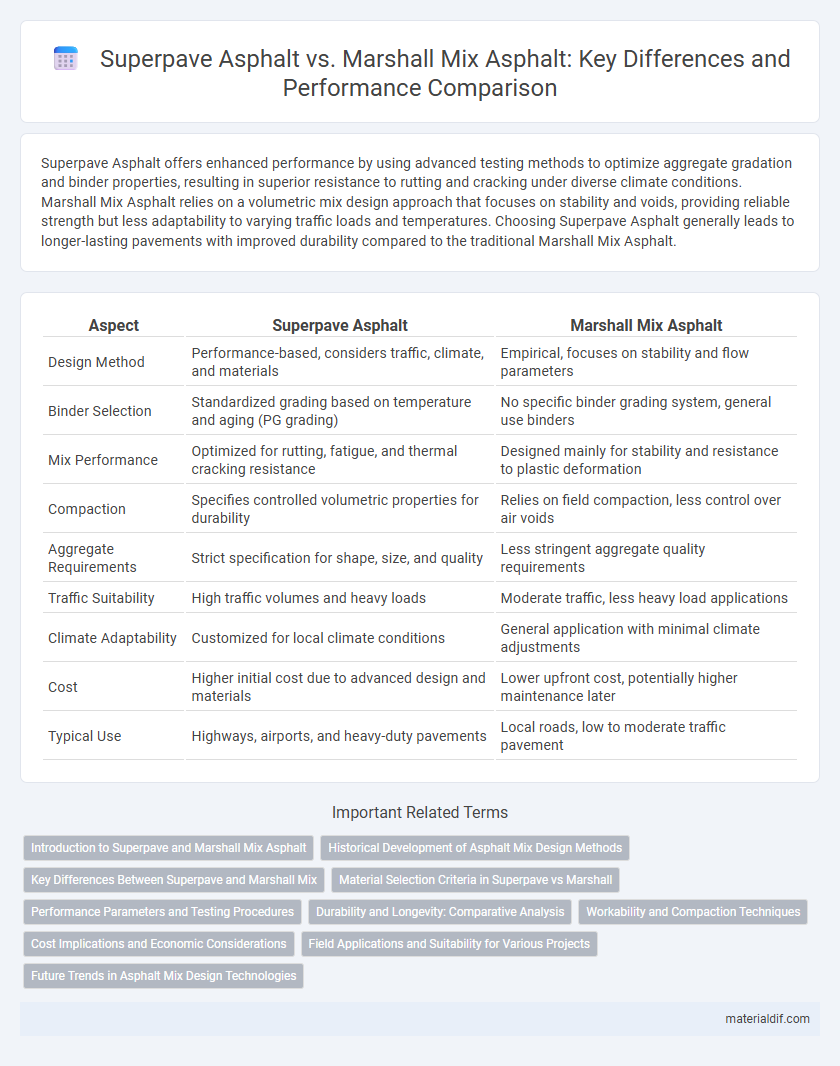

| Aspect | Superpave Asphalt | Marshall Mix Asphalt |

|---|---|---|

| Design Method | Performance-based, considers traffic, climate, and materials | Empirical, focuses on stability and flow parameters |

| Binder Selection | Standardized grading based on temperature and aging (PG grading) | No specific binder grading system, general use binders |

| Mix Performance | Optimized for rutting, fatigue, and thermal cracking resistance | Designed mainly for stability and resistance to plastic deformation |

| Compaction | Specifies controlled volumetric properties for durability | Relies on field compaction, less control over air voids |

| Aggregate Requirements | Strict specification for shape, size, and quality | Less stringent aggregate quality requirements |

| Traffic Suitability | High traffic volumes and heavy loads | Moderate traffic, less heavy load applications |

| Climate Adaptability | Customized for local climate conditions | General application with minimal climate adjustments |

| Cost | Higher initial cost due to advanced design and materials | Lower upfront cost, potentially higher maintenance later |

| Typical Use | Highways, airports, and heavy-duty pavements | Local roads, low to moderate traffic pavement |

Introduction to Superpave and Marshall Mix Asphalt

Superpave Asphalt utilizes a performance-based approach that considers climate, traffic loading, and material properties to design durable pavements tailored for specific conditions. In contrast, Marshall Mix Asphalt relies on volumetric criteria and empirical methods, emphasizing stability, flow, and air voids for mix design. Superpave offers enhanced rutting and cracking resistance by optimizing aggregate gradation and binder selection compared to the more traditional Marshall Mix method.

Historical Development of Asphalt Mix Design Methods

Superpave asphalt mix design was developed in the 1990s through the Strategic Highway Research Program to address limitations found in the traditional Marshall mix method, which originated in the 1930s. Superpave incorporates performance-based criteria using advanced aggregate gradation and binder specifications, improving pavement durability and resistance to rutting and fatigue cracking. The Marshall method relies on empirical data and confined compaction procedures, making it less adaptive to modern traffic and climatic conditions compared to the performance-driven Superpave system.

Key Differences Between Superpave and Marshall Mix

Superpave Asphalt utilizes advanced performance-based criteria and environmental data to tailor mixtures, whereas Marshall Mix Asphalt relies primarily on volumetric properties and empirical testing. Superpave incorporates aggregate gradation and binder selection optimized for specific climatic and traffic conditions, leading to improved durability and rut resistance. Marshall Mix is simpler and widely used for its cost-effectiveness but may lack the adaptive performance characteristics found in Superpave designs.

Material Selection Criteria in Superpave vs Marshall

Superpave asphalt utilizes performance-graded binders selected based on climate and traffic loading to enhance durability, whereas Marshall mix primarily relies on empirical criteria without explicit climate consideration. Superpave incorporates aggregate gradation tailored to optimize rutting and fatigue resistance, while Marshall mix uses fixed gradation ranges focused on stability and flow values. Material selection in Superpave emphasizes mechanistic-empirical design and performance testing, resulting in mixtures better suited for varying environmental and traffic conditions compared to the Marshall method.

Performance Parameters and Testing Procedures

Superpave Asphalt employs performance-based criteria such as dynamic modulus and flow number obtained from advanced testing methods like the Superpave Shear Tester, optimizing pavement resistance to rutting, fatigue, and thermal cracking. In contrast, Marshall Mix Asphalt relies on empirical parameters including stability, flow, and air voids determined through the Marshall Stability test, which primarily assesses mixture compaction and strength. Superpave's performance-oriented approach offers a more comprehensive evaluation of asphalt behavior under varying traffic loads and climatic conditions compared to the traditional Marshall method.

Durability and Longevity: Comparative Analysis

Superpave asphalt outperforms Marshall mix asphalt in durability due to its advanced aggregate selection and binder performance grading, which enhance resistance to rutting, cracking, and moisture damage. Marshall mix relies on empirical methods that may not account for varying traffic loads and climate conditions, leading to shorter pavement life under heavy use. Studies show Superpave pavements maintain structural integrity and surface quality significantly longer, reducing maintenance costs and extending service life by up to 30% compared to Marshall mix asphalt.

Workability and Compaction Techniques

Superpave Asphalt offers superior workability through advanced aggregate selection and binder performance, enhancing mix consistency during placement. Marshall Mix Asphalt relies on traditional compaction techniques using a standard number of blows, which may limit adaptation to varying traffic loads. The optimized gradation and volumetric criteria of Superpave enable better compaction uniformity and pavement durability under diverse environmental conditions.

Cost Implications and Economic Considerations

Superpave asphalt typically incurs higher initial costs due to advanced material selection and performance-based mix design, but offers longer pavement life and reduced maintenance expenses. Marshall mix asphalt is more cost-effective upfront with simpler design procedures but may require more frequent repairs, increasing long-term costs. Economic considerations favor Superpave in high-traffic or harsh climate areas where lifecycle cost savings outweigh initial investment.

Field Applications and Suitability for Various Projects

Superpave asphalt offers superior performance in diverse environmental conditions and heavy traffic loads, making it ideal for highways and urban roads requiring enhanced durability and rut resistance. Marshall mix asphalt, known for its simplicity and cost-effectiveness, is suitable for low to moderate traffic roads and smaller projects where ease of construction is prioritized. Field applications favor Superpave in areas with extreme temperature variations, while Marshall remains popular for routine maintenance and local streets.

Future Trends in Asphalt Mix Design Technologies

Superpave asphalt mix design integrates advanced performance grading and volumetric analysis, predicting pavement behavior under diverse climate and loading conditions more accurately than Marshall mix. Emerging trends emphasize incorporating recycled materials and warm-mix technologies within Superpave frameworks to enhance sustainability and reduce environmental impact. Continued innovation in computer modeling and performance-based specifications drives the evolution of asphalt mix designs, optimizing durability and lifecycle cost efficiency.

Superpave Asphalt vs Marshall Mix Asphalt Infographic

materialdif.com

materialdif.com