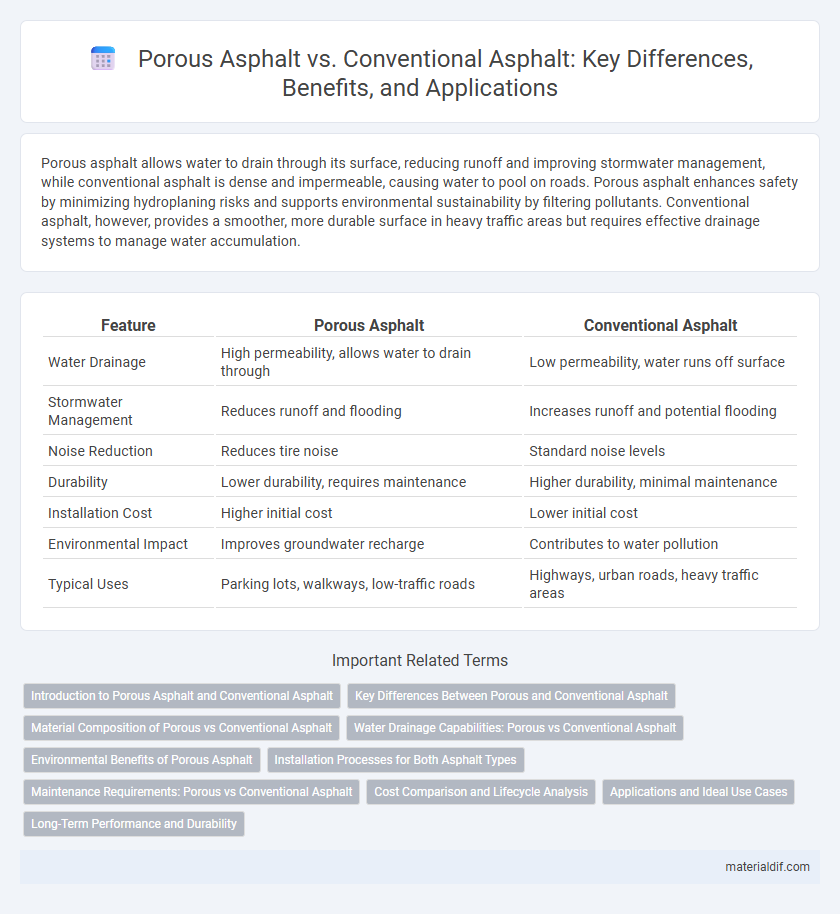

Porous asphalt allows water to drain through its surface, reducing runoff and improving stormwater management, while conventional asphalt is dense and impermeable, causing water to pool on roads. Porous asphalt enhances safety by minimizing hydroplaning risks and supports environmental sustainability by filtering pollutants. Conventional asphalt, however, provides a smoother, more durable surface in heavy traffic areas but requires effective drainage systems to manage water accumulation.

Table of Comparison

| Feature | Porous Asphalt | Conventional Asphalt |

|---|---|---|

| Water Drainage | High permeability, allows water to drain through | Low permeability, water runs off surface |

| Stormwater Management | Reduces runoff and flooding | Increases runoff and potential flooding |

| Noise Reduction | Reduces tire noise | Standard noise levels |

| Durability | Lower durability, requires maintenance | Higher durability, minimal maintenance |

| Installation Cost | Higher initial cost | Lower initial cost |

| Environmental Impact | Improves groundwater recharge | Contributes to water pollution |

| Typical Uses | Parking lots, walkways, low-traffic roads | Highways, urban roads, heavy traffic areas |

Introduction to Porous Asphalt and Conventional Asphalt

Porous asphalt is engineered to allow water to pass through its surface, reducing runoff and improving stormwater management, while conventional asphalt is a dense, impermeable material designed primarily for durability and load-bearing capacity. Porous asphalt consists of a mixture with fewer fines, creating interconnected voids that facilitate drainage, whereas conventional asphalt uses a tighter aggregate matrix that prevents water infiltration. This fundamental difference makes porous asphalt ideal for sustainable urban drainage systems, while conventional asphalt remains preferred for high-traffic roadways requiring long-term strength.

Key Differences Between Porous and Conventional Asphalt

Porous asphalt features a permeable structure designed to allow water infiltration, significantly reducing surface runoff and improving stormwater management, unlike conventional asphalt which is dense and non-porous. Conventional asphalt provides a smooth, durable surface ideal for heavy traffic load-bearing but lacks drainage capabilities, leading to increased water accumulation and potential hydroplaning risks. The porous variety requires specialized maintenance to prevent clogging, whereas conventional asphalt typically demands standard sealing and crack repairs.

Material Composition of Porous vs Conventional Asphalt

Porous asphalt consists of a gap-graded aggregate mix with minimal fine particles, allowing water to flow through its interconnected voids for enhanced drainage. Conventional asphalt uses a dense-graded aggregate with fine particles filled by asphalt binder to create a impermeable, solid surface. The material composition difference directly impacts their permeability, durability, and suitability for various environmental conditions.

Water Drainage Capabilities: Porous vs Conventional Asphalt

Porous asphalt features interconnected voids that allow water to permeate through the surface, significantly reducing runoff and promoting groundwater recharge. Conventional asphalt is dense and impermeable, causing water to accumulate on the surface and increasing the risk of flooding and hydroplaning. The superior water drainage capabilities of porous asphalt make it ideal for sustainable urban drainage systems and stormwater management.

Environmental Benefits of Porous Asphalt

Porous asphalt significantly improves stormwater management by allowing rainwater to infiltrate directly through the pavement, reducing runoff and minimizing the risk of flooding. This permeability helps filter pollutants and recharges groundwater, promoting healthier ecosystems compared to conventional asphalt that channels water to drainage systems. Furthermore, porous asphalt mitigates urban heat island effects by enabling faster cooling through water evaporation, contributing to lower ambient temperatures in paved areas.

Installation Processes for Both Asphalt Types

Porous asphalt installation requires a carefully prepared aggregate base with high void content to facilitate water drainage, followed by precise layering and compaction of the porous asphalt mix to maintain permeability. Conventional asphalt installation involves a denser aggregate base and uses a standard asphalt mix that is compacted to create a smooth, impermeable surface. Both processes demand specialized equipment and skilled labor, but porous asphalt needs more attention to material selection and moisture management during installation to ensure long-term functionality.

Maintenance Requirements: Porous vs Conventional Asphalt

Porous asphalt requires more frequent inspection and cleaning to prevent clogging and ensure effective water drainage, whereas conventional asphalt typically demands less frequent maintenance primarily focused on crack and pothole repairs. Maintaining porous asphalt involves routine vacuuming or pressure washing to preserve permeability, which is crucial for stormwater management. Conventional asphalt maintenance centers on sealing and patching to extend pavement life and maintain surface integrity.

Cost Comparison and Lifecycle Analysis

Porous asphalt typically costs 10-15% more upfront than conventional asphalt due to specialized materials and installation techniques, but it reduces stormwater management expenses by allowing natural infiltration. Lifecycle analysis reveals porous asphalt's durability of 8-12 years under moderate traffic, slightly shorter than conventional asphalt's 15-20 years, yet maintenance costs are lower due to decreased water damage and reduced need for drainage infrastructure. Evaluating total ownership cost, porous asphalt offers long-term savings through environmental benefits and regulatory compliance, offsetting initial premium investments.

Applications and Ideal Use Cases

Porous asphalt is ideal for urban areas and parking lots where stormwater management and runoff reduction are crucial, as its permeable structure allows water to drain through the pavement, reducing flooding and improving groundwater recharge. Conventional asphalt suits high-traffic roads, highways, and industrial zones due to its dense composition, providing superior durability and resistance to heavy loads and wear. Choosing porous asphalt benefits sustainable design projects, while conventional asphalt remains the preferred choice for long-lasting, high-strength pavement in demanding transportation infrastructure.

Long-Term Performance and Durability

Porous asphalt enhances long-term performance by improving water drainage, reducing hydroplaning risks, and minimizing freeze-thaw damage, which extends pavement lifespan compared to conventional asphalt. Conventional asphalt offers greater structural strength but is more susceptible to surface water pooling and subsequent cracking over time. Durability of porous asphalt depends on proper maintenance to prevent clogging, while conventional asphalt generally requires less upkeep but may need more frequent repairs due to water-related deterioration.

Porous Asphalt vs Conventional Asphalt Infographic

materialdif.com

materialdif.com