Polymer-modified asphalt enhances pavement durability by improving elasticity, resistance to deformation, and temperature susceptibility compared to unmodified asphalt. This type of asphalt reduces cracking and rutting in extreme weather conditions, extending the lifespan of roads. Unmodified asphalt, while cost-effective, tends to be more prone to wear and damage under heavy traffic and temperature fluctuations.

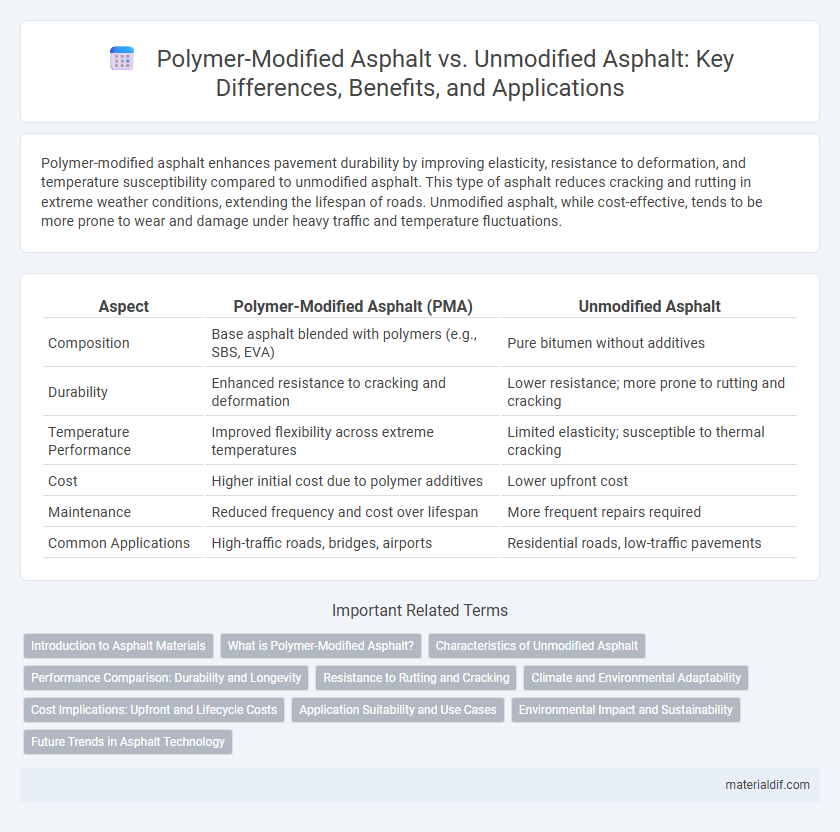

Table of Comparison

| Aspect | Polymer-Modified Asphalt (PMA) | Unmodified Asphalt |

|---|---|---|

| Composition | Base asphalt blended with polymers (e.g., SBS, EVA) | Pure bitumen without additives |

| Durability | Enhanced resistance to cracking and deformation | Lower resistance; more prone to rutting and cracking |

| Temperature Performance | Improved flexibility across extreme temperatures | Limited elasticity; susceptible to thermal cracking |

| Cost | Higher initial cost due to polymer additives | Lower upfront cost |

| Maintenance | Reduced frequency and cost over lifespan | More frequent repairs required |

| Common Applications | High-traffic roads, bridges, airports | Residential roads, low-traffic pavements |

Introduction to Asphalt Materials

Polymer-modified asphalt incorporates polymers such as styrene-butadiene-styrene (SBS) to enhance flexibility, elasticity, and resistance to deformation compared to unmodified asphalt. Unmodified asphalt, primarily composed of bitumen, offers basic adhesive and waterproofing properties but lacks superior performance under extreme temperatures and heavy traffic loads. The modification with polymers improves durability, reduces cracking and rutting, and extends pavement lifespan, making it a preferred choice for demanding road construction projects.

What is Polymer-Modified Asphalt?

Polymer-modified asphalt (PMA) is asphalt binder enhanced with polymers such as styrene-butadiene-styrene (SBS) or crumb rubber to improve its performance characteristics. This modification increases resistance to deformation, cracking, and temperature fluctuations compared to unmodified asphalt. PMA offers superior durability and flexibility, making it ideal for high-traffic and extreme weather conditions.

Characteristics of Unmodified Asphalt

Unmodified asphalt exhibits a predominantly flexible and adhesive nature, characterized by its lower resistance to temperature fluctuations and susceptibility to rutting under heavy traffic loads. It lacks the enhanced elasticity and improved durability found in polymer-modified asphalt, resulting in increased cracking and deformation over time. The inherent properties of unmodified asphalt make it more cost-effective but less suitable for high-performance applications requiring extended lifespan and superior mechanical strength.

Performance Comparison: Durability and Longevity

Polymer-modified asphalt significantly enhances durability and longevity compared to unmodified asphalt by improving resistance to cracking, rutting, and aging under extreme temperature variations. The incorporation of polymers increases flexibility and elasticity, allowing it to better withstand heavy traffic loads and environmental stresses over time. Studies show polymer-modified asphalt can extend pavement life by up to 50%, reducing maintenance costs and improving overall pavement performance.

Resistance to Rutting and Cracking

Polymer-modified asphalt enhances resistance to rutting by increasing elasticity and deformation recovery under high temperatures compared to unmodified asphalt. It also improves cracking resistance through better flexibility and tensile strength, reducing thermal and fatigue cracks over time. Unmodified asphalt typically shows lower durability in extreme weather, leading to faster pavement distress and maintenance needs.

Climate and Environmental Adaptability

Polymer-modified asphalt provides superior durability and flexibility compared to unmodified asphalt, enhancing its adaptability to extreme temperature fluctuations and reducing cracking in both hot and cold climates. Its improved resistance to deformation and aging contributes to longer pavement lifespan and less frequent maintenance, lowering overall environmental impact. Unmodified asphalt tends to perform adequately in mild climates but is more susceptible to thermal degradation and moisture damage, limiting its effectiveness in harsher environmental conditions.

Cost Implications: Upfront and Lifecycle Costs

Polymer-modified asphalt (PMA) incurs higher upfront costs compared to unmodified asphalt due to the addition of polymers that enhance performance. Despite the initial investment, PMA offers extended lifecycle benefits by reducing maintenance frequency and improving resistance to rutting and cracking. Over time, the reduced repair expenses and increased pavement durability result in lower overall lifecycle costs, making PMA a cost-effective choice for long-term infrastructure projects.

Application Suitability and Use Cases

Polymer-modified asphalt demonstrates superior performance in high-traffic highways and airport runways due to enhanced elasticity and resistance to deformation, making it ideal for areas subjected to heavy loads and extreme temperatures. Unmodified asphalt remains suitable for residential roads and low-traffic urban streets where cost-effectiveness and standard durability meet performance needs. The enhanced bonding and flexibility of polymer-modified variants reduce cracking and rutting, extending pavement lifespan in demanding applications.

Environmental Impact and Sustainability

Polymer-modified asphalt significantly enhances pavement durability and reduces the frequency of repairs, leading to lower resource consumption and diminished carbon emissions over the lifecycle compared to unmodified asphalt. The improved resistance to cracking and rutting in polymer-modified asphalt minimizes maintenance activities, thereby reducing the environmental footprint associated with frequent resurfacing and material extraction. Unmodified asphalt, while less energy-intensive during production, generally results in shorter pavement lifespan and increased raw material use, contributing to greater environmental degradation and waste generation.

Future Trends in Asphalt Technology

Polymer-modified asphalt (PMA) demonstrates superior durability, flexibility, and resistance to temperature fluctuations compared to unmodified asphalt, making it pivotal in the development of next-generation pavements. Emerging trends emphasize enhanced polymer formulations and nano-modification techniques to improve performance and sustainability in road construction. Advances in recycling technologies for PMA also contribute to reducing environmental impact while extending pavement lifecycle in future infrastructure projects.

Polymer-modified asphalt vs Unmodified asphalt Infographic

materialdif.com

materialdif.com