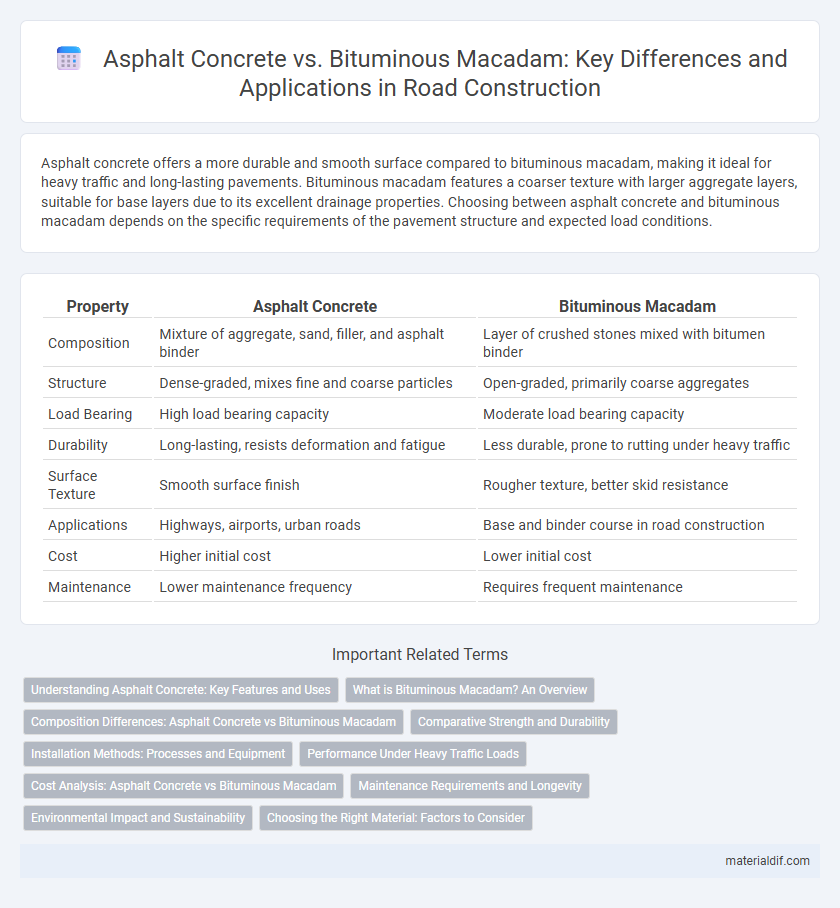

Asphalt concrete offers a more durable and smooth surface compared to bituminous macadam, making it ideal for heavy traffic and long-lasting pavements. Bituminous macadam features a coarser texture with larger aggregate layers, suitable for base layers due to its excellent drainage properties. Choosing between asphalt concrete and bituminous macadam depends on the specific requirements of the pavement structure and expected load conditions.

Table of Comparison

| Property | Asphalt Concrete | Bituminous Macadam |

|---|---|---|

| Composition | Mixture of aggregate, sand, filler, and asphalt binder | Layer of crushed stones mixed with bitumen binder |

| Structure | Dense-graded, mixes fine and coarse particles | Open-graded, primarily coarse aggregates |

| Load Bearing | High load bearing capacity | Moderate load bearing capacity |

| Durability | Long-lasting, resists deformation and fatigue | Less durable, prone to rutting under heavy traffic |

| Surface Texture | Smooth surface finish | Rougher texture, better skid resistance |

| Applications | Highways, airports, urban roads | Base and binder course in road construction |

| Cost | Higher initial cost | Lower initial cost |

| Maintenance | Lower maintenance frequency | Requires frequent maintenance |

Understanding Asphalt Concrete: Key Features and Uses

Asphalt concrete consists of a mixture of aggregates and bitumen, providing a durable and flexible surface ideal for high-traffic roads and highways. It offers superior load-bearing capacity and resistance to deformation compared to bituminous macadam, which uses larger aggregates and a comparatively less dense binder. Commonly used in urban infrastructure, asphalt concrete ensures smooth ride quality and long-lasting pavement performance under diverse weather conditions.

What is Bituminous Macadam? An Overview

Bituminous Macadam (BM) is a composite pavement material consisting of crushed stone aggregates coated with bitumen, providing a durable and flexible surface. Unlike Asphalt Concrete, which uses fine aggregates and filler materials to create a dense and smooth texture, BM features larger, angular aggregates that enhance load distribution and drainage. This makes Bituminous Macadam ideal for base and intermediate road layers, offering strength and resistance to deformation under heavy traffic.

Composition Differences: Asphalt Concrete vs Bituminous Macadam

Asphalt concrete consists of a dense mixture of aggregates bound by a high-grade asphalt binder, providing superior stability and durability for heavy traffic loads. Bituminous macadam features a coarser aggregate structure with a bitumen coating that offers flexibility and ease of maintenance, commonly used in lighter traffic conditions. The primary composition difference lies in the finer aggregate matrix and higher bitumen content in asphalt concrete compared to the more open-graded, layered structure of bituminous macadam.

Comparative Strength and Durability

Asphalt Concrete exhibits higher compressive strength and superior durability compared to Bituminous Macadam due to its dense-graded aggregate structure and polymer-modified binders. Bituminous Macadam, while more flexible and easier to repair, typically shows lower resistance to rutting and fatigue cracking under heavy traffic loads. Enhanced stability of Asphalt Concrete makes it the preferred choice for high-traffic road surfaces requiring long-term performance.

Installation Methods: Processes and Equipment

Asphalt concrete installation involves mixing aggregates with a bitumen binder at high temperatures, followed by laying and compacting using pavers and roller compactors to create a dense, durable surface. Bituminous macadam uses a similar layering process but typically involves a coarser aggregate base with bitumen applied as a binding coat, compacted with pneumatic or steel roller equipment for flexibility and drainage. Both methods require specialized machinery such as hot mix plants, bitumen sprayers, and graders for precise material distribution and compaction.

Performance Under Heavy Traffic Loads

Asphalt Concrete demonstrates superior performance under heavy traffic loads due to its dense, well-compacted structure that provides enhanced load distribution and durability compared to Bituminous Macadam. Bituminous Macadam, while flexible and cost-effective, is prone to deformation and rutting in high-stress conditions because of its open-graded aggregate and less binder content. Pavement designs favor Asphalt Concrete for highways and industrial areas where sustained heavy traffic demands long-term resilience and reduced maintenance.

Cost Analysis: Asphalt Concrete vs Bituminous Macadam

Asphalt concrete generally incurs higher upfront costs compared to bituminous macadam due to its more complex mixing and laying processes, but it offers greater durability and longer service life, reducing maintenance expenses over time. Bituminous macadam proves cost-effective for projects with budget constraints or lower traffic loads, given its simpler production and application methods. Evaluating long-term performance and maintenance frequency is essential for accurate cost-benefit analysis between asphalt concrete and bituminous macadam.

Maintenance Requirements and Longevity

Asphalt concrete demonstrates superior durability and lower maintenance requirements compared to bituminous macadam, largely due to its dense, impermeable surface that resists water infiltration and load stresses. Bituminous macadam, consisting of a coarser aggregate mix with less binder, is more prone to surface wear and requires more frequent sealing and patching to prevent deterioration. The longevity of asphalt concrete typically exceeds 15-20 years under moderate traffic conditions, while bituminous macadam often needs resurfacing within 7-10 years to maintain performance.

Environmental Impact and Sustainability

Asphalt concrete offers enhanced durability and reduced maintenance frequency, resulting in lower long-term environmental impact compared to bituminous macadam, which requires more frequent repairs and resurfacing. The production of asphalt concrete can incorporate recycled materials like reclaimed asphalt pavement (RAP), promoting sustainability by minimizing raw material extraction and reducing landfill waste. In contrast, bituminous macadam's less dense structure leads to higher permeability, potentially increasing pollutant runoff and soil contamination risks.

Choosing the Right Material: Factors to Consider

When selecting between asphalt concrete and bituminous macadam, factors such as load-bearing capacity, durability, and surface finish are critical. Asphalt concrete offers superior strength and smoother finishes, ideal for high-traffic roads, while bituminous macadam provides cost-effective flexibility suitable for low to medium traffic conditions. Climate and maintenance needs also influence the choice, with asphalt concrete performing better in extreme weather and requiring less frequent repairs.

Asphalt Concrete vs Bituminous Macadam Infographic

materialdif.com

materialdif.com