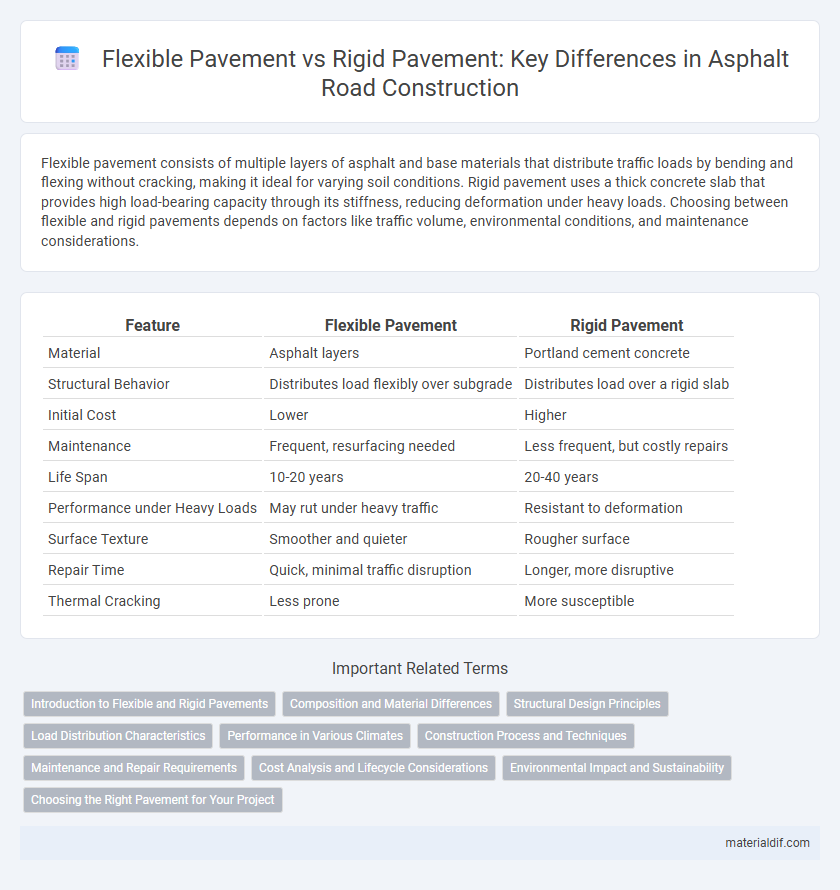

Flexible pavement consists of multiple layers of asphalt and base materials that distribute traffic loads by bending and flexing without cracking, making it ideal for varying soil conditions. Rigid pavement uses a thick concrete slab that provides high load-bearing capacity through its stiffness, reducing deformation under heavy loads. Choosing between flexible and rigid pavements depends on factors like traffic volume, environmental conditions, and maintenance considerations.

Table of Comparison

| Feature | Flexible Pavement | Rigid Pavement |

|---|---|---|

| Material | Asphalt layers | Portland cement concrete |

| Structural Behavior | Distributes load flexibly over subgrade | Distributes load over a rigid slab |

| Initial Cost | Lower | Higher |

| Maintenance | Frequent, resurfacing needed | Less frequent, but costly repairs |

| Life Span | 10-20 years | 20-40 years |

| Performance under Heavy Loads | May rut under heavy traffic | Resistant to deformation |

| Surface Texture | Smoother and quieter | Rougher surface |

| Repair Time | Quick, minimal traffic disruption | Longer, more disruptive |

| Thermal Cracking | Less prone | More susceptible |

Introduction to Flexible and Rigid Pavements

Flexible pavements consist of multiple layers of asphalt and granular materials that distribute traffic loads over a wide area of the subgrade, adapting to minor ground movements without cracking. Rigid pavements use a thick slab of Portland cement concrete that provides high load-bearing capacity and distributes vehicle weight over a smaller subgrade area due to its high modulus of elasticity. The choice between flexible and rigid pavements depends on factors such as traffic load, subgrade conditions, climate, and maintenance requirements.

Composition and Material Differences

Flexible pavement consists primarily of asphalt concrete composed of bitumen binder and aggregates, allowing it to distribute loads through layer deformation. Rigid pavement is mainly made from Portland cement concrete with embedded steel reinforcement, offering high structural rigidity and load transfer through slab action. The fundamental material difference lies in the viscoelastic properties of bitumen in flexible pavements versus the brittle, high-strength characteristics of cement concrete in rigid pavements.

Structural Design Principles

Flexible pavement relies on a layered system where loads are distributed through successive layers, with the asphalt surface designed to flex under traffic loads while protecting the underlying base and subgrade. Rigid pavement uses a concrete slab that distributes loads over a wide area through its high modulus of elasticity and slab action, minimizing deflections and stresses on the subgrade. Structural design principles for flexible pavement emphasize layer thickness and material resilience, whereas rigid pavement design focuses on slab thickness, joint placement, and load transfer mechanisms.

Load Distribution Characteristics

Flexible pavement distributes loads through layered granular materials, allowing stress to gradually dissipate into the subgrade, which reduces localized pressure. Rigid pavement relies on the high modulus of concrete to spread loads over a wider area of the subgrade, minimizing deflection and strain on the underlying layers. Load distribution in rigid pavement is typically more uniform, leading to longer service life under heavy traffic conditions.

Performance in Various Climates

Flexible pavement adapts effectively to temperature fluctuations and slight ground movements, maintaining durability in diverse climatic conditions such as hot summers and cold winters. Rigid pavement offers superior load distribution and resists deformation under heavy traffic but may crack in freeze-thaw cycles common in colder climates. Performance in various climates depends on factors like thermal expansion, moisture sensitivity, and load-bearing capacity, making material selection critical for pavement longevity.

Construction Process and Techniques

Flexible pavement construction involves layering of bituminous materials over a prepared subgrade, using a base course of crushed aggregates to distribute loads evenly. Rigid pavement construction requires the placement of reinforced Portland cement concrete slabs supported by a well-compacted subbase for stiffness and load transfer. Techniques for flexible pavements emphasize compaction and proper binder application, while rigid pavements focus on precise slab thickness, joint placement, and curing methods to prevent cracking.

Maintenance and Repair Requirements

Flexible pavement requires more frequent maintenance due to its susceptibility to surface wear, rutting, and cracking, but repairs such as patching and overlaying are generally quicker and less costly. Rigid pavement, while more durable and less prone to deformation, demands less frequent maintenance but involves more complex and expensive repairs, often requiring slab replacement or joint sealing. The choice between flexible and rigid pavement impacts long-term maintenance budgets and operational downtime.

Cost Analysis and Lifecycle Considerations

Flexible pavement typically incurs lower initial construction costs due to the use of asphalt layers, which allow for easier and quicker installation compared to rigid pavement's concrete slabs. Lifecycle cost analysis reveals that while rigid pavement demands higher upfront investment, it offers longer service life and reduced maintenance expenses over time, often exceeding 30 years with minimal repairs. Cost efficiency depends on traffic load, environmental conditions, and maintenance strategies, making flexible pavement more suitable for lighter loads and shorter lifespans, whereas rigid pavement suits heavy-duty roads requiring durability and longevity.

Environmental Impact and Sustainability

Flexible pavement primarily uses bitumen, a petroleum-based material, which contributes to carbon emissions during production and application, yet offers easier recycling options through milling and reuse of asphalt materials. Rigid pavement, composed mainly of concrete with cement as a key ingredient, has a higher embodied energy and CO2 footprint due to cement manufacturing but typically requires less frequent maintenance and has a longer lifespan, reducing overall environmental impact over time. Sustainable pavement practices emphasize using recycled materials, optimizing design for durability, and incorporating green technologies to minimize resource consumption and carbon footprint in both flexible and rigid pavement systems.

Choosing the Right Pavement for Your Project

Flexible pavement, composed of asphalt layers, adapts to subgrade movements and is ideal for roads requiring quick construction and cost-effectiveness, especially under moderate traffic loads. Rigid pavement, made from reinforced concrete, offers higher durability, lower maintenance, and better performance under heavy traffic and industrial loads, making it suitable for highways and airports. Evaluating traffic volume, soil conditions, initial budget, and long-term maintenance expenses ensures selecting the pavement type that maximizes project longevity and cost efficiency.

Flexible Pavement vs Rigid Pavement Infographic

materialdif.com

materialdif.com