Asphalt binder is a viscous black material derived from crude oil, primarily used as the glue in hot mix asphalt to hold aggregate particles together. Asphalt emulsion consists of asphalt binder droplets suspended in water with the help of an emulsifying agent, enabling application at lower temperatures and better workability on cooler surfaces. Choosing between asphalt binder and asphalt emulsion depends on project requirements, environmental conditions, and desired curing times.

Table of Comparison

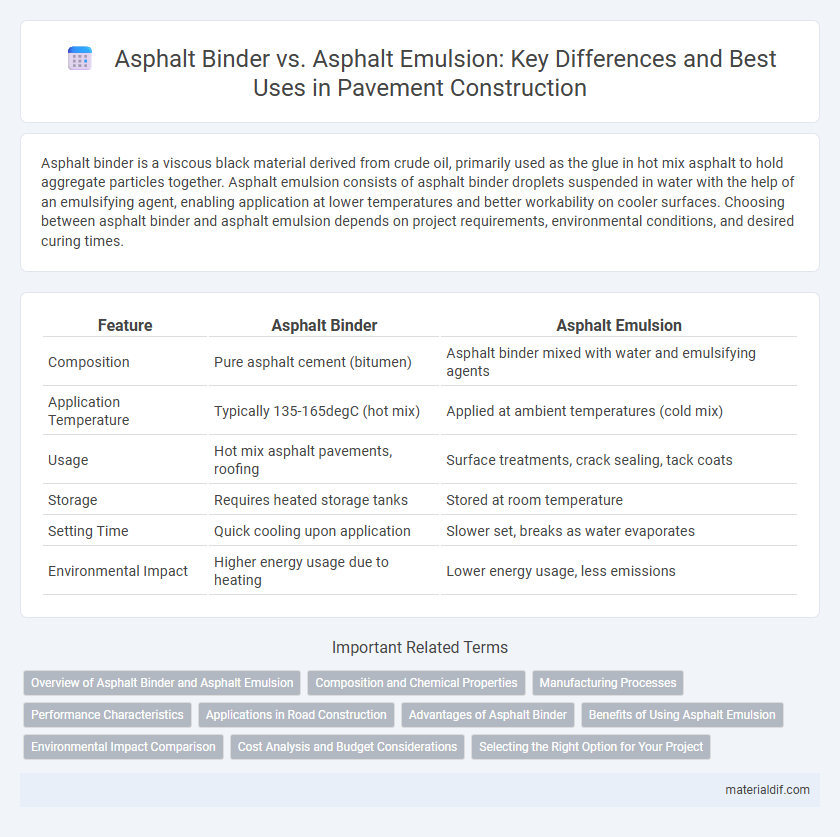

| Feature | Asphalt Binder | Asphalt Emulsion |

|---|---|---|

| Composition | Pure asphalt cement (bitumen) | Asphalt binder mixed with water and emulsifying agents |

| Application Temperature | Typically 135-165degC (hot mix) | Applied at ambient temperatures (cold mix) |

| Usage | Hot mix asphalt pavements, roofing | Surface treatments, crack sealing, tack coats |

| Storage | Requires heated storage tanks | Stored at room temperature |

| Setting Time | Quick cooling upon application | Slower set, breaks as water evaporates |

| Environmental Impact | Higher energy usage due to heating | Lower energy usage, less emissions |

Overview of Asphalt Binder and Asphalt Emulsion

Asphalt binder is a viscous, black petroleum product primarily used as a key ingredient in hot mix asphalt concrete, providing durability and adhesive properties to aggregates. Asphalt emulsion consists of asphalt droplets suspended in water with emulsifying agents, allowing for easier handling and application at lower temperatures, especially in surface treatment and cold mix applications. Both materials enhance pavement performance but differ in composition, application methods, and temperature requirements.

Composition and Chemical Properties

Asphalt binder primarily consists of bitumen, a viscous petroleum-derived hydrocarbon material, characterized by its high molecular weight and hydrophobic properties, which provide strong adhesive qualities and durability in pavement applications. Asphalt emulsion, in contrast, is a mixture of finely dispersed asphalt droplets suspended in water using emulsifying agents such as surfactants, resulting in a material with temporary hydrophilic properties and lower viscosity. The chemical properties of asphalt binder include resistance to oxidation and thermal stability, whereas asphalt emulsion exhibits enhanced workability and faster curing due to water evaporation and demulsifier action.

Manufacturing Processes

Asphalt binder is produced by refining crude oil through vacuum distillation and air blowing to achieve the desired viscosity and performance characteristics. Asphalt emulsion is manufactured by combining asphalt binder with water and emulsifying agents using high-shear mixers to create a stable mixture suitable for cold applications. The key distinction lies in asphalt binder's pure, heated form versus asphalt emulsion's chemically stabilized, water-based formulation.

Performance Characteristics

Asphalt binder provides superior durability and high-temperature stability, making it ideal for long-lasting pavement applications with excellent resistance to deformation and cracking. Asphalt emulsion offers improved workability and faster curing times due to its water-based formulation, enhancing ease of application in cooler or wet conditions. Performance characteristics of asphalt emulsion emphasize flexibility and adhesion, whereas asphalt binder prioritizes strength and thermal resistance.

Applications in Road Construction

Asphalt binder, a viscous petroleum product, is primarily used in hot mix asphalt for constructing durable, high-traffic roads, providing strong adhesion and long-term stability. Asphalt emulsion, a mixture of asphalt binder and water with emulsifying agents, is favored in cold mix applications, surface treatments, and maintenance due to its ease of use at lower temperatures and quicker curing. Road construction projects utilize asphalt binder for base and surface layers requiring high performance, while asphalt emulsion is ideal for patching, fog seals, and recycling asphalt pavements.

Advantages of Asphalt Binder

Asphalt binder offers superior durability and load-bearing capacity compared to asphalt emulsion, making it ideal for high-traffic roadways and long-term pavement performance. Its higher viscosity ensures better adhesion and resistance to water damage, reducing the risks of rutting and cracking under heavy loads. Asphalt binder's ability to withstand extreme temperatures enhances overall pavement lifespan, minimizing maintenance costs and increasing road safety.

Benefits of Using Asphalt Emulsion

Asphalt emulsion offers enhanced workability and faster curing times compared to asphalt binder, making it ideal for surface treatments and repairs. Its water-based formulation reduces volatile organic compounds (VOCs), promoting environmentally friendly construction practices. The emulsified nature improves adhesion to aggregates, providing longer-lasting pavement performance under various weather conditions.

Environmental Impact Comparison

Asphalt binders, primarily derived from petroleum, exhibit a higher environmental footprint due to energy-intensive refining and increased emissions during production compared to asphalt emulsions, which utilize water to reduce VOC emissions and require lower processing temperatures. Asphalt emulsions contribute to reduced greenhouse gas emissions and lower energy consumption, enhancing sustainability in pavement construction and maintenance. The water-based nature of asphalt emulsions also minimizes the release of hazardous fumes, making them a more environmentally friendly alternative for road infrastructure projects.

Cost Analysis and Budget Considerations

Asphalt binder typically incurs higher upfront costs due to its refined composition and heating requirements, whereas asphalt emulsion offers cost savings with lower temperature application and reduced energy consumption. Budget considerations favor asphalt emulsion for large-scale projects seeking efficient resource allocation and quicker project turnaround. Long-term maintenance and performance factors also influence the overall cost-effectiveness, with asphalt binder sometimes justifying its premium through enhanced durability.

Selecting the Right Option for Your Project

Asphalt binder is a viscous petroleum product used primarily for hot mix asphalt, offering strong adhesive properties and durability for high-traffic roadways. Asphalt emulsion, a mixture of asphalt binder, water, and emulsifying agents, is suitable for cold mix applications and surface treatments, providing easier handling and faster curing times. Selecting the right option depends on project conditions, temperature availability, and required performance characteristics to optimize longevity and cost-efficiency.

Asphalt Binder vs Asphalt Emulsion Infographic

materialdif.com

materialdif.com