Thermal cracking occurs in asphalt when temperature fluctuations cause contraction and expansion, leading to brittle fractures typically seen in cold climates. Fatigue cracking results from repeated traffic loading, gradually weakening the pavement and forming interconnected cracks under sustained stress. Understanding the distinct causes and mechanisms of thermal versus fatigue cracking is essential for designing durable asphalt pavements tailored to specific environmental and load conditions.

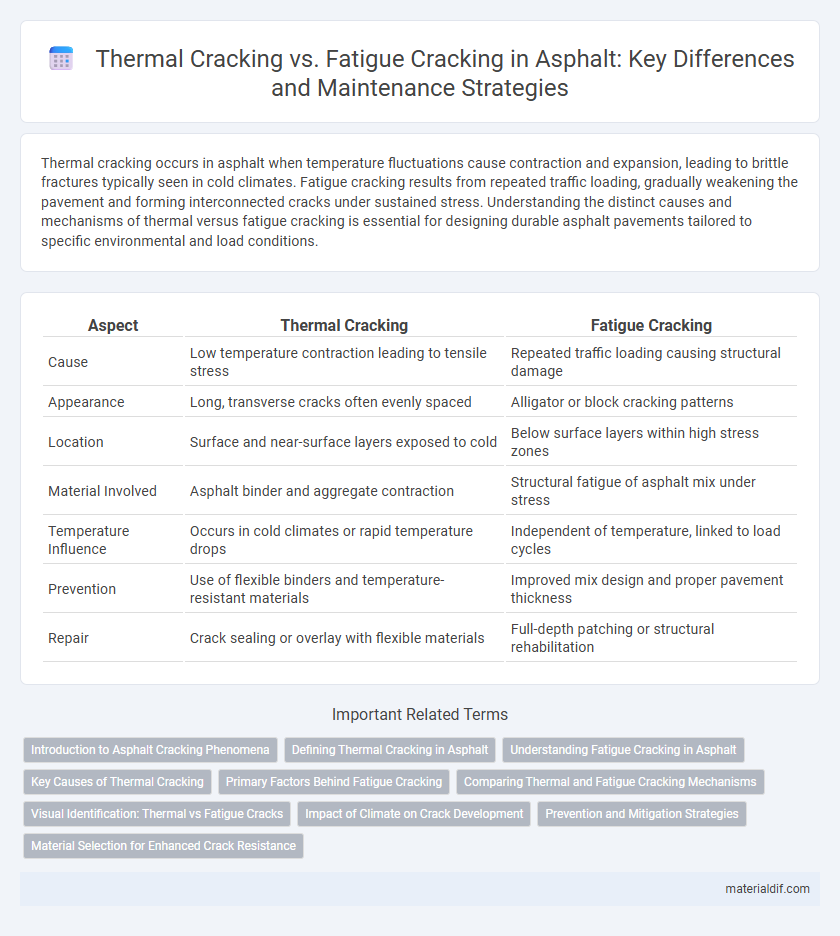

Table of Comparison

| Aspect | Thermal Cracking | Fatigue Cracking |

|---|---|---|

| Cause | Low temperature contraction leading to tensile stress | Repeated traffic loading causing structural damage |

| Appearance | Long, transverse cracks often evenly spaced | Alligator or block cracking patterns |

| Location | Surface and near-surface layers exposed to cold | Below surface layers within high stress zones |

| Material Involved | Asphalt binder and aggregate contraction | Structural fatigue of asphalt mix under stress |

| Temperature Influence | Occurs in cold climates or rapid temperature drops | Independent of temperature, linked to load cycles |

| Prevention | Use of flexible binders and temperature-resistant materials | Improved mix design and proper pavement thickness |

| Repair | Crack sealing or overlay with flexible materials | Full-depth patching or structural rehabilitation |

Introduction to Asphalt Cracking Phenomena

Thermal cracking in asphalt occurs due to low temperatures causing contraction and brittleness, leading to transverse cracks, while fatigue cracking results from repeated traffic loading causing cumulative damage along wheel paths. These two primary cracking mechanisms significantly influence pavement durability and maintenance strategies. Understanding the distinct causes and manifestations of thermal and fatigue cracking is critical for designing resilient asphalt mixtures and extending pavement lifespan.

Defining Thermal Cracking in Asphalt

Thermal cracking in asphalt occurs when low temperatures cause the pavement to contract and become brittle, leading to the formation of cracks. This type of distress typically appears as longitudinal cracks and is a result of the asphalt's inability to flex without fracturing under thermal stress. Identifying thermal cracking is crucial for selecting appropriate materials and pavement designs that enhance resistance to cold climate conditions.

Understanding Fatigue Cracking in Asphalt

Fatigue cracking in asphalt occurs due to repeated traffic loading that causes micro-cracks to propagate and eventually form visible cracks on the pavement surface. This type of cracking is primarily influenced by the asphalt binder's flexibility and the aggregate's interlock within the mix, impacting the pavement's durability over time. Proper mix design and quality control are critical to minimizing fatigue cracking and extending the service life of asphalt pavements.

Key Causes of Thermal Cracking

Thermal cracking in asphalt primarily results from low-temperature contraction, causing the pavement to shrink and develop transverse cracks. The key causes include rapid temperature drops, poor mix design with insufficient asphalt binder flexibility, and inadequate pavement thickness. These factors lead to stiffness and brittleness, reducing the pavement's ability to withstand temperature-induced stresses over time.

Primary Factors Behind Fatigue Cracking

Fatigue cracking in asphalt primarily arises from repeated traffic loading that induces tensile stresses and strain accumulation over time, causing micro-cracks to propagate through the pavement. Key factors influencing fatigue cracking include the pavement's material properties such as binder stiffness and aggregate gradation, as well as environmental conditions like temperature fluctuations and moisture infiltration. Unlike thermal cracking, which results from low-temperature contraction, fatigue cracking is dominated by mechanical stress cycles that exceed the asphalt's capacity to recover, leading to structural degradation.

Comparing Thermal and Fatigue Cracking Mechanisms

Thermal cracking in asphalt occurs due to temperature-induced contraction causing tensile stresses that exceed the material's strength, primarily during rapid cooling or low temperatures. Fatigue cracking results from repeated traffic loading causing cumulative damage and micro-crack propagation that weaken the asphalt over time. Comparing these mechanisms, thermal cracking is driven by environmental temperature fluctuations, whereas fatigue cracking is influenced by mechanical stress cycles and pavement structural design.

Visual Identification: Thermal vs Fatigue Cracks

Thermal cracking in asphalt appears as long, interconnected transverse cracks caused by low temperatures inducing contraction, typically forming a web-like pattern across the pavement surface. Fatigue cracking, in contrast, manifests as alligator or crocodile cracks with interconnected, irregular shapes resulting from repetitive traffic loading and structural failure. Visual identification hinges on crack patterns: thermal cracks are usually narrow and linear, while fatigue cracks are wider, jagged, and clustered in high-stress areas.

Impact of Climate on Crack Development

Thermal cracking in asphalt primarily occurs due to temperature fluctuations causing contraction and tensile stress, with colder climates accelerating crack initiation through freeze-thaw cycles. Fatigue cracking, conversely, results from repeated traffic loading, but its severity is exacerbated under warmer climates where asphalt softens, reducing its resistance to deformation. Climate-driven moisture penetration further weakens the asphalt binder, intensifying both thermal and fatigue crack propagation.

Prevention and Mitigation Strategies

Thermal cracking in asphalt results from temperature-induced shrinkage, requiring strategies like using polymer-modified binders and optimizing asphalt mix designs to enhance flexibility and reduce brittleness. Fatigue cracking arises from repeated traffic loading, mitigated by improving pavement structural thickness, using high-quality aggregates, and ensuring proper compaction to distribute stresses evenly. Applying rejuvenators and timely maintenance such as crack sealing also extends pavement life by addressing early signs of both thermal and fatigue cracking.

Material Selection for Enhanced Crack Resistance

Thermal cracking in asphalt occurs due to temperature-induced contraction, while fatigue cracking results from repeated traffic loading, necessitating different material properties for resistance. Selecting asphalt binders with improved low-temperature flexibility and modifiers like polymers enhances resistance to thermal cracking by reducing brittleness. For fatigue cracking, incorporating materials with high elasticity and toughness, such as crumb rubber or SBS-modified binders, improves the pavement's ability to withstand cyclic loading without cracking.

Thermal Cracking vs Fatigue Cracking Infographic

materialdif.com

materialdif.com