Bituminous concrete consists of crushed stone mixed with bitumen, offering excellent durability and load-bearing capacity for roads and highways. Mastic asphalt, on the other hand, is a dense, impermeable mix of bitumen, sand, and fine aggregates, providing superior waterproofing and flexibility for roofing and flooring applications. Choosing between the two depends on project requirements, with bituminous concrete preferred for structural strength and mastic asphalt for moisture resistance.

Table of Comparison

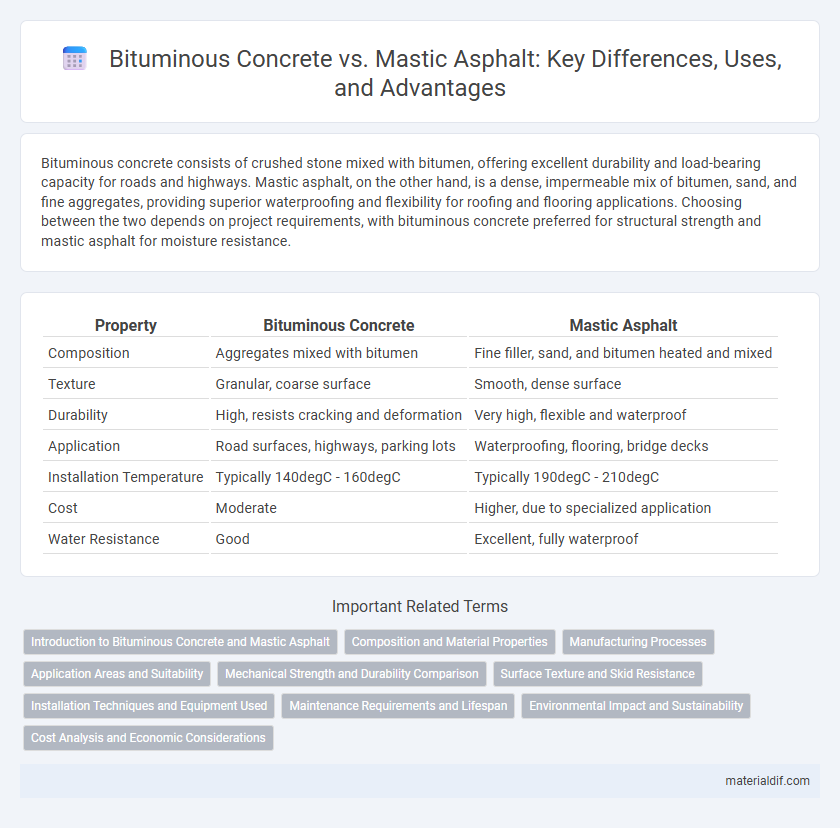

| Property | Bituminous Concrete | Mastic Asphalt |

|---|---|---|

| Composition | Aggregates mixed with bitumen | Fine filler, sand, and bitumen heated and mixed |

| Texture | Granular, coarse surface | Smooth, dense surface |

| Durability | High, resists cracking and deformation | Very high, flexible and waterproof |

| Application | Road surfaces, highways, parking lots | Waterproofing, flooring, bridge decks |

| Installation Temperature | Typically 140degC - 160degC | Typically 190degC - 210degC |

| Cost | Moderate | Higher, due to specialized application |

| Water Resistance | Good | Excellent, fully waterproof |

Introduction to Bituminous Concrete and Mastic Asphalt

Bituminous concrete is a composite material composed of mineral aggregates bound together with bitumen, primarily used for road surfacing and pavements due to its durability and flexibility. Mastic asphalt, also known as sheet asphalt, is a dense, impermeable mixture of bitumen, fine aggregates, and filler materials that provides a waterproof and wear-resistant surface ideal for roofing and flooring applications. Both materials utilize bitumen as a binder, but bituminous concrete emphasizes aggregate size and structural strength, while mastic asphalt focuses on a smooth, seamless surface finish.

Composition and Material Properties

Bituminous concrete consists of aggregates bound by bitumen, offering high compressive strength and durability suitable for heavy traffic loads. Mastic asphalt is a homogenous, voidless material composed of bitumen, limestone powder, and fine aggregates, providing superior waterproofing and flexibility. The difference in composition results in bituminous concrete being more rigid and load-bearing, while mastic asphalt excels in resistance to water penetration and thermal movement.

Manufacturing Processes

Bituminous concrete is produced by heating and mixing aggregates with a bitumen binder at temperatures typically between 150-170degC, resulting in a flexible, durable pavement material suitable for highways. Mastic asphalt manufacturing involves heating a blend of bitumen, limestone filler, and fine aggregates at lower temperatures around 200degC, creating a dense, impermeable material ideal for waterproofing and industrial flooring. The key difference lies in the temperature-controlled mixing stages and the aggregate composition, which influence the final performance characteristics and application areas of each asphalt type.

Application Areas and Suitability

Bituminous concrete is widely used for road surfaces, parking lots, and airport runways due to its excellent load-bearing capacity and durability under heavy traffic conditions. Mastic asphalt is ideal for waterproofing applications, such as roofing and bridge decks, thanks to its impermeability and resistance to water infiltration. The choice between bituminous concrete and mastic asphalt depends on the specific requirements of structural integrity versus waterproofing performance in infrastructure projects.

Mechanical Strength and Durability Comparison

Bituminous concrete offers superior mechanical strength due to its granular composition and well-graded aggregate distribution, making it ideal for high-traffic roadways requiring enhanced load-bearing capacity. Mastic asphalt provides exceptional durability and waterproofing properties due to its dense, homogeneous mixture of bitumen and fine aggregates, which resists deformation and water infiltration over extended periods. The choice between bituminous concrete and mastic asphalt depends on specific performance needs, where bituminous concrete excels in structural support and mastic asphalt outperforms in environmental resistance and longevity.

Surface Texture and Skid Resistance

Bituminous concrete offers a rougher surface texture due to its granular aggregate mix, enhancing skid resistance and making it suitable for high-traffic roads. Mastic asphalt, characterized by a smooth, dense surface, provides excellent waterproofing but typically has lower skid resistance compared to bituminous concrete. The choice between these materials depends on the required balance between durability, surface texture, and safety performance on different road types.

Installation Techniques and Equipment Used

Bituminous concrete installation involves layering hot asphalt mixtures followed by compaction using vibratory rollers and pavers designed for precise thickness control. Mastic asphalt requires specialized heating equipment to maintain its flowability and is applied in a molten state without compaction, using hand tools or floats to achieve a smooth, impervious surface. Equipment choices for bituminous concrete emphasize mechanical compaction efficiency, whereas mastic asphalt installation relies on temperature control and manual finishing for durability and water resistance.

Maintenance Requirements and Lifespan

Bituminous concrete requires regular maintenance such as sealing cracks and periodic resurfacing to extend its average lifespan of 10 to 15 years. Mastic asphalt, with its dense, impermeable composition, demands minimal upkeep and can last over 25 years under similar traffic conditions. The superior durability and reduced maintenance costs of mastic asphalt make it a preferred choice for heavy-duty pavements and high-traffic urban areas.

Environmental Impact and Sustainability

Bituminous concrete, composed of aggregates bound with bitumen, offers recyclability through reclaimed asphalt pavement, reducing landfill waste and conserving natural resources in road construction. Mastic asphalt, known for its durability and impermeability, minimizes maintenance frequency, thereby lowering resource consumption and greenhouse gas emissions over its lifecycle. Both materials contribute to sustainable infrastructure, but bituminous concrete's enhanced recyclability presents a stronger advantage in environmental impact reduction.

Cost Analysis and Economic Considerations

Bituminous concrete typically offers a lower initial cost compared to mastic asphalt, making it a preferred choice for budget-sensitive projects. Mastic asphalt, while more expensive upfront, provides superior durability and reduced maintenance expenses over time, which can lead to lower life-cycle costs. Economic considerations favor bituminous concrete for short-term projects, whereas mastic asphalt is cost-effective for long-term infrastructure requiring enhanced waterproofing and load-bearing capacity.

Bituminous Concrete vs Mastic Asphalt Infographic

materialdif.com

materialdif.com