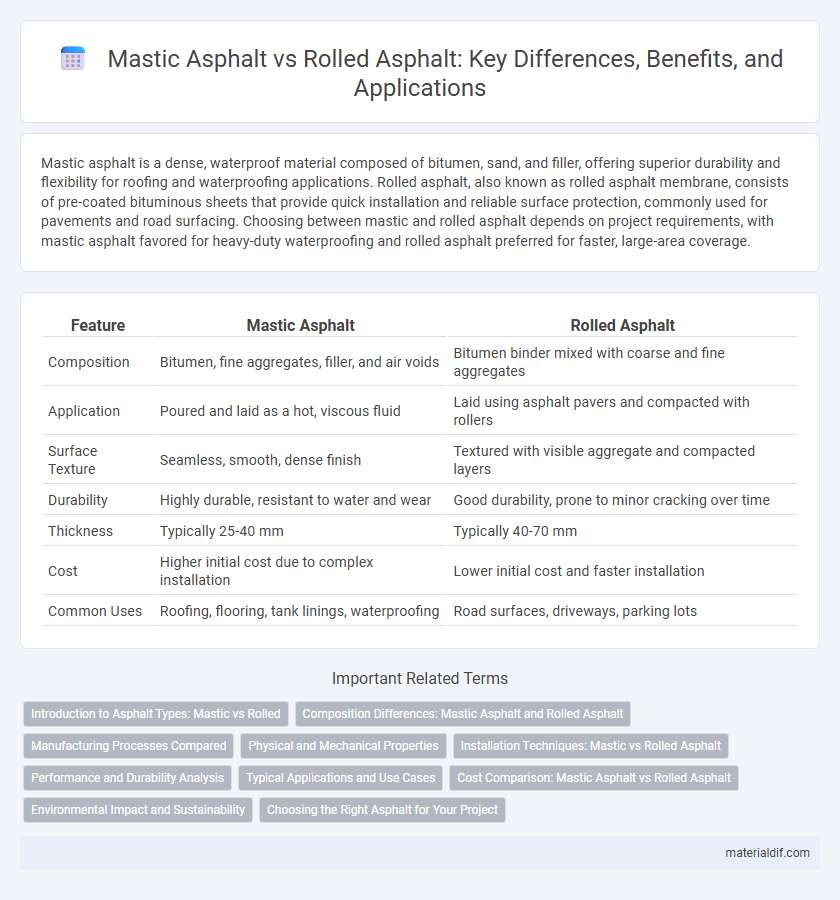

Mastic asphalt is a dense, waterproof material composed of bitumen, sand, and filler, offering superior durability and flexibility for roofing and waterproofing applications. Rolled asphalt, also known as rolled asphalt membrane, consists of pre-coated bituminous sheets that provide quick installation and reliable surface protection, commonly used for pavements and road surfacing. Choosing between mastic and rolled asphalt depends on project requirements, with mastic asphalt favored for heavy-duty waterproofing and rolled asphalt preferred for faster, large-area coverage.

Table of Comparison

| Feature | Mastic Asphalt | Rolled Asphalt |

|---|---|---|

| Composition | Bitumen, fine aggregates, filler, and air voids | Bitumen binder mixed with coarse and fine aggregates |

| Application | Poured and laid as a hot, viscous fluid | Laid using asphalt pavers and compacted with rollers |

| Surface Texture | Seamless, smooth, dense finish | Textured with visible aggregate and compacted layers |

| Durability | Highly durable, resistant to water and wear | Good durability, prone to minor cracking over time |

| Thickness | Typically 25-40 mm | Typically 40-70 mm |

| Cost | Higher initial cost due to complex installation | Lower initial cost and faster installation |

| Common Uses | Roofing, flooring, tank linings, waterproofing | Road surfaces, driveways, parking lots |

Introduction to Asphalt Types: Mastic vs Rolled

Mastic asphalt is a dense, smooth, and waterproof material composed of bitumen, sand, and filler, offering exceptional durability and flexibility ideal for complex surfaces and waterproofing. Rolled asphalt, also known as hot mix asphalt, consists of a mixture of bitumen and aggregates compacted by rollers, providing a hard, load-bearing surface commonly used in road construction. Understanding the distinct composition and application methods of mastic and rolled asphalt helps optimize performance for specific infrastructure needs.

Composition Differences: Mastic Asphalt and Rolled Asphalt

Mastic asphalt consists primarily of bitumen binder thoroughly mixed with fine aggregates and filler, creating a dense, impermeable material ideal for waterproofing and heavy-duty flooring. Rolled asphalt combines bitumen with larger aggregates, producing a coarser texture designed for road surfaces requiring durability and skid resistance. The fundamental difference in composition lies in aggregate size and bitumen content, influencing each material's mechanical properties and specific application suitability.

Manufacturing Processes Compared

Mastic asphalt is produced by heating bitumen with fine fillers and limestone powder to create a dense, plastic mixture that is poured and compacted in a heated state, offering superior waterproofing and durability. Rolled asphalt involves mixing bitumen with coarse aggregates at lower temperatures, then spreading and compacting it with rollers to achieve a firm, textured surface suitable for roads. The manufacturing of mastic asphalt requires precise temperature control and extended heating times, while rolled asphalt benefits from faster production and laying processes, making each ideal for different application requirements.

Physical and Mechanical Properties

Mastic asphalt offers superior waterproofing and flexibility due to its dense, homogeneous composition, making it ideal for roofing and flooring applications where durability under thermal expansion is critical. Rolled asphalt, characterized by its layered construction and granular texture, provides enhanced load distribution and skid resistance, which is essential for road surfaces exposed to heavy traffic. The mechanical strength of rolled asphalt generally exceeds mastic asphalt in bearing heavy vehicular loads, while mastic's physical properties favor resistance to water penetration and deformation.

Installation Techniques: Mastic vs Rolled Asphalt

Mastic asphalt installation involves heating the material to a fluid state before pouring and leveling it using hand tools, ensuring a seamless, fully compacted surface ideal for waterproofing and durability. Rolled asphalt is applied hot and spread using a paver machine, then compacted with heavy rollers to create a dense, smooth surface suited for high-traffic roads. The key difference lies in mastic asphalt's manual, heat-controlled method providing enhanced impermeability, whereas rolled asphalt relies on mechanical spreading and rolling for rapid installation and strength.

Performance and Durability Analysis

Mastic asphalt demonstrates superior waterproofing and flexibility due to its dense, homogenous composition, making it ideal for complex surfaces and environments with heavy thermal stress. Rolled asphalt provides faster installation and quicker curing times but may be prone to cracking and rutting under prolonged heavy traffic conditions. Performance and durability analyses reveal mastic asphalt's extended lifespan and low maintenance requirements compared to rolled asphalt, particularly in areas with severe weather exposure and high load demands.

Typical Applications and Use Cases

Mastic asphalt is commonly used for waterproofing roofs, flooring, and tanking due to its excellent impermeability and flexibility, making it ideal for complex structures and areas requiring seamless surfaces. Rolled asphalt is primarily applied in roadways, highways, and parking lots, offering high durability and load-bearing capacity necessary for heavy traffic conditions. Both materials serve distinct purposes based on their composition, with mastic asphalt favored for long-lasting waterproofing and rolled asphalt for robust pavement construction.

Cost Comparison: Mastic Asphalt vs Rolled Asphalt

Mastic asphalt generally incurs higher initial costs due to its complex manufacturing and installation processes compared to rolled asphalt, which is more economical and faster to lay. Maintenance expenses tend to be lower for mastic asphalt because of its durability and resistance to water ingress, offering long-term savings. Rolled asphalt requires more frequent repairs and resurfacing, increasing lifecycle costs despite its initial affordability.

Environmental Impact and Sustainability

Mastic asphalt demonstrates superior environmental benefits due to its longer lifespan and lower maintenance needs, reducing resource consumption and waste generation over time. Rolled asphalt, while quicker to install, often requires more frequent repairs, increasing carbon emissions and material use. Sustainable practices favor mastic asphalt for its durability and lower ecological footprint in road construction projects.

Choosing the Right Asphalt for Your Project

Mastic asphalt offers superior waterproofing and durability, making it ideal for flat roofs and areas requiring seamless surfaces, while rolled asphalt provides cost-effective paving for roads and driveways with quicker installation. Consider project-specific factors like load-bearing requirements, environmental exposure, and budget constraints to determine the optimal asphalt type. Evaluating these criteria ensures selecting the right asphalt for long-lasting performance and value.

Mastic Asphalt vs Rolled Asphalt Infographic

materialdif.com

materialdif.com