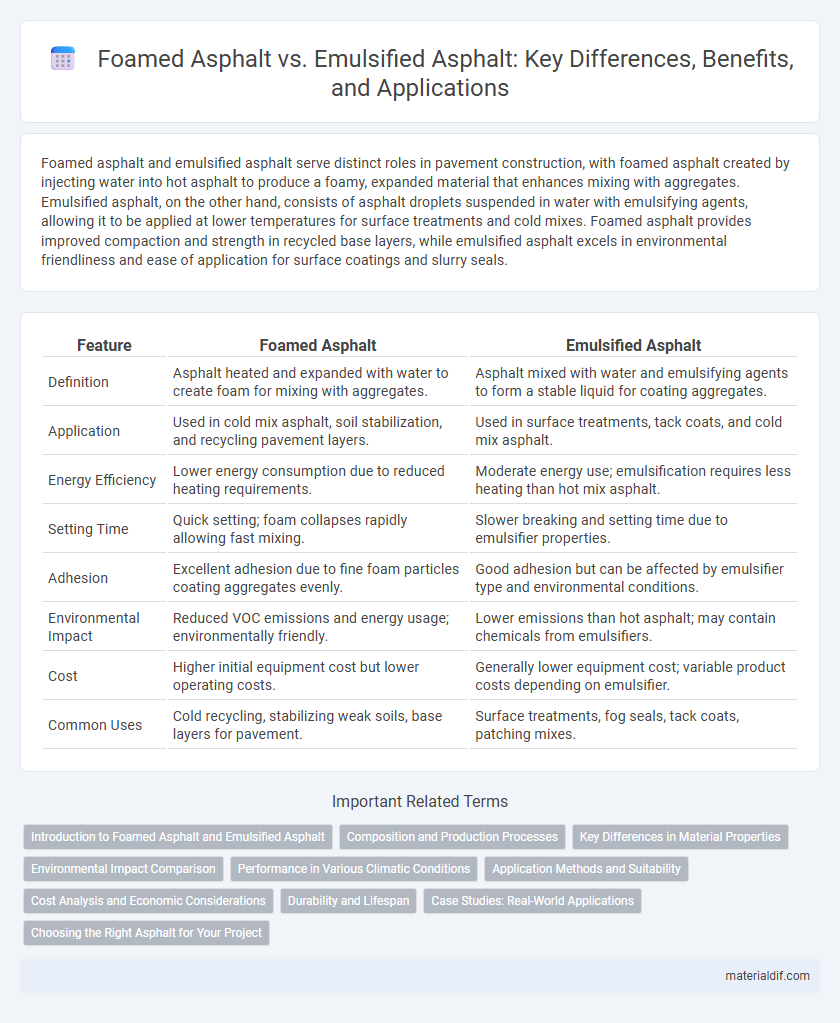

Foamed asphalt and emulsified asphalt serve distinct roles in pavement construction, with foamed asphalt created by injecting water into hot asphalt to produce a foamy, expanded material that enhances mixing with aggregates. Emulsified asphalt, on the other hand, consists of asphalt droplets suspended in water with emulsifying agents, allowing it to be applied at lower temperatures for surface treatments and cold mixes. Foamed asphalt provides improved compaction and strength in recycled base layers, while emulsified asphalt excels in environmental friendliness and ease of application for surface coatings and slurry seals.

Table of Comparison

| Feature | Foamed Asphalt | Emulsified Asphalt |

|---|---|---|

| Definition | Asphalt heated and expanded with water to create foam for mixing with aggregates. | Asphalt mixed with water and emulsifying agents to form a stable liquid for coating aggregates. |

| Application | Used in cold mix asphalt, soil stabilization, and recycling pavement layers. | Used in surface treatments, tack coats, and cold mix asphalt. |

| Energy Efficiency | Lower energy consumption due to reduced heating requirements. | Moderate energy use; emulsification requires less heating than hot mix asphalt. |

| Setting Time | Quick setting; foam collapses rapidly allowing fast mixing. | Slower breaking and setting time due to emulsifier properties. |

| Adhesion | Excellent adhesion due to fine foam particles coating aggregates evenly. | Good adhesion but can be affected by emulsifier type and environmental conditions. |

| Environmental Impact | Reduced VOC emissions and energy usage; environmentally friendly. | Lower emissions than hot asphalt; may contain chemicals from emulsifiers. |

| Cost | Higher initial equipment cost but lower operating costs. | Generally lower equipment cost; variable product costs depending on emulsifier. |

| Common Uses | Cold recycling, stabilizing weak soils, base layers for pavement. | Surface treatments, fog seals, tack coats, patching mixes. |

Introduction to Foamed Asphalt and Emulsified Asphalt

Foamed asphalt is produced by injecting water into hot asphalt binder, causing it to expand and create a foam that improves aggregate coating and compaction in cold mix applications. Emulsified asphalt consists of asphalt droplets suspended in water with an emulsifying agent, allowing it to be applied at lower temperatures and providing slow-setting benefits for surface treatments and cold mixes. Both foamed and emulsified asphalts enhance pavement performance by improving workability, durability, and environmental sustainability in road construction.

Composition and Production Processes

Foamed asphalt is produced by injecting small amounts of water into hot liquid asphalt, causing it to expand and form a foam with increased volume and reduced viscosity, which improves mixing with aggregates. Emulsified asphalt consists of asphalt droplets suspended in water with the help of emulsifying agents, created by blending asphalt, water, and chemical surfactants under controlled conditions. The key difference lies in foamed asphalt's physical expansion and volatilization-based production, whereas emulsified asphalt relies on chemical stabilization to maintain a liquid state at lower temperatures.

Key Differences in Material Properties

Foamed asphalt features expanded bitumen formed by injecting small amounts of water and air into heated asphalt, resulting in increased volume and improved workability, while emulsified asphalt consists of bitumen droplets suspended in water stabilized by emulsifying agents, offering slower curing times and enhanced adhesion to aggregates. The primary material property difference lies in temperature sensitivity; foamed asphalt requires precise heating for optimal foaming, whereas emulsified asphalt cures at ambient temperatures through water evaporation. These distinctions influence pavement performance, with foamed asphalt providing better compaction and stability in cold mixes and emulsified asphalt facilitating easier mixing and recycling processes.

Environmental Impact Comparison

Foamed asphalt significantly reduces aggregate heating temperatures, leading to lower greenhouse gas emissions compared to traditional hot mix methods, while emulsified asphalt primarily lowers energy consumption by allowing cold or warm mix applications. The water-based nature of emulsified asphalt minimizes volatile organic compound (VOC) emissions, promoting healthier air quality during application. Both technologies offer sustainable alternatives to conventional asphalt production, but foamed asphalt's reduction in fuel usage and emissions provides a more substantial environmental benefit in large-scale pavement projects.

Performance in Various Climatic Conditions

Foamed asphalt exhibits superior performance in colder climates due to its enhanced adhesion and faster curing times, which reduce the risk of frost damage and improve crack resistance. Emulsified asphalt performs better in warmer, wetter climates by providing greater flexibility and moisture resistance, preventing rutting and stripping under high temperatures and heavy rainfall. Selecting between foamed and emulsified asphalt depends on specific regional climate factors such as temperature fluctuations, precipitation levels, and freeze-thaw cycles to optimize road durability and lifespan.

Application Methods and Suitability

Foamed asphalt is produced by injecting small amounts of water into hot asphalt, creating a lightweight, aerated binder ideal for cold mix applications and base stabilization on granular soils, offering rapid curing and strong adhesive properties. Emulsified asphalt consists of asphalt droplets suspended in water, suitable for surface treatments, chip seals, and cold mix paving, providing flexibility and ease of application at lower temperatures. Selection between these methods depends on project requirements, with foamed asphalt favored for soil stabilization due to quick strength gain, while emulsified asphalt suits surface maintenance and repair where slower curing and extended working time are advantageous.

Cost Analysis and Economic Considerations

Foamed asphalt typically incurs higher initial costs due to specialized equipment and increased energy consumption during production, but it offers long-term economic benefits through faster curing times and improved pavement performance, reducing maintenance expenses. Emulsified asphalt generally has lower upfront costs and simpler application processes, making it more cost-effective for projects with budget constraints and less demanding durability requirements. Economic considerations must weigh foamed asphalt's lifecycle savings against emulsified asphalt's immediate affordability to determine the optimal choice for pavement rehabilitation and construction projects.

Durability and Lifespan

Foamed asphalt provides enhanced durability due to its superior bonding strength and moisture resistance, resulting in a longer lifespan for pavement structures compared to emulsified asphalt. Emulsified asphalt, while effective for surface treatments and repairs, typically exhibits reduced durability under heavy traffic and environmental stress, leading to more frequent maintenance cycles. The choice between foamed and emulsified asphalt significantly impacts pavement longevity, with foamed asphalt preferred for base stabilization and high-durability applications.

Case Studies: Real-World Applications

Foamed asphalt has demonstrated superior performance in pavement rehabilitation projects by enhancing soil stabilization and increasing load-bearing capacity, as evidenced in case studies from highway construction in Australia and the United States. Emulsified asphalt has proven effective in surface treatments and maintenance, showing cost-efficiency and rapid curing times in municipal road preservation efforts across Europe. Comparative analyses reveal that foamed asphalt excels in deep stabilization, while emulsified asphalt is preferred for surface applications, optimizing durability and lifecycle costs in real-world scenarios.

Choosing the Right Asphalt for Your Project

Foamed asphalt offers superior compaction and stability, making it ideal for base and sub-base road construction with high load requirements. Emulsified asphalt excels in surface treatments and tack coats, providing enhanced adhesion and moisture resistance for existing pavement layers. Selecting the right asphalt depends on project goals, traffic conditions, and environmental factors to ensure durability and cost-effectiveness.

Foamed Asphalt vs Emulsified Asphalt Infographic

materialdif.com

materialdif.com