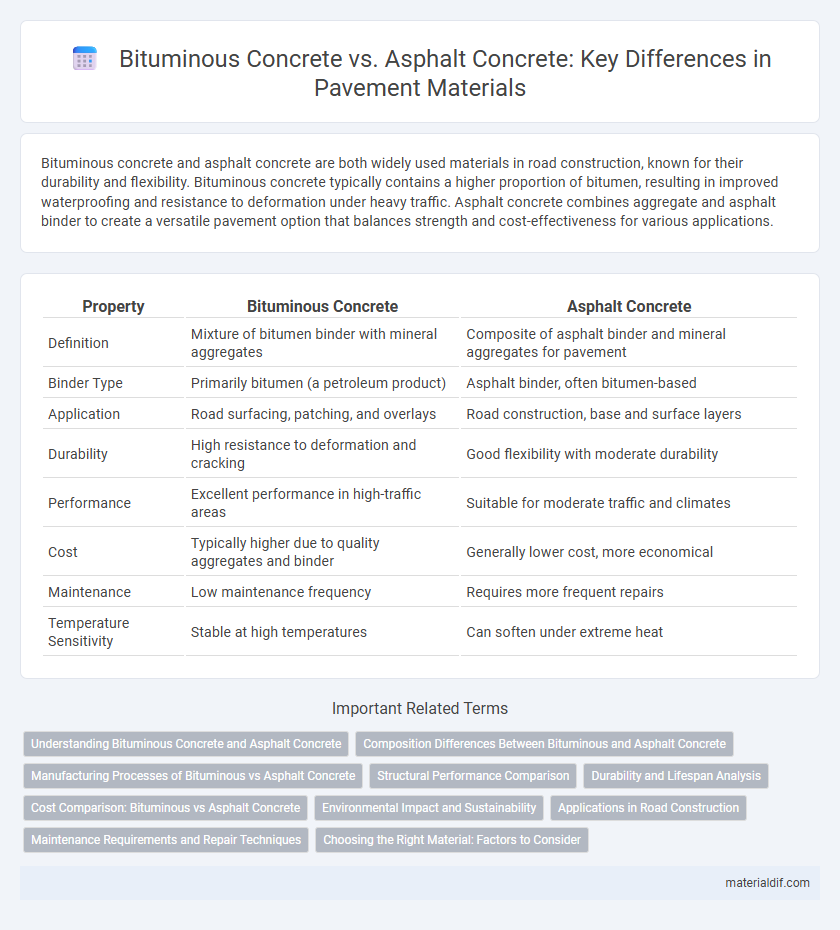

Bituminous concrete and asphalt concrete are both widely used materials in road construction, known for their durability and flexibility. Bituminous concrete typically contains a higher proportion of bitumen, resulting in improved waterproofing and resistance to deformation under heavy traffic. Asphalt concrete combines aggregate and asphalt binder to create a versatile pavement option that balances strength and cost-effectiveness for various applications.

Table of Comparison

| Property | Bituminous Concrete | Asphalt Concrete |

|---|---|---|

| Definition | Mixture of bitumen binder with mineral aggregates | Composite of asphalt binder and mineral aggregates for pavement |

| Binder Type | Primarily bitumen (a petroleum product) | Asphalt binder, often bitumen-based |

| Application | Road surfacing, patching, and overlays | Road construction, base and surface layers |

| Durability | High resistance to deformation and cracking | Good flexibility with moderate durability |

| Performance | Excellent performance in high-traffic areas | Suitable for moderate traffic and climates |

| Cost | Typically higher due to quality aggregates and binder | Generally lower cost, more economical |

| Maintenance | Low maintenance frequency | Requires more frequent repairs |

| Temperature Sensitivity | Stable at high temperatures | Can soften under extreme heat |

Understanding Bituminous Concrete and Asphalt Concrete

Bituminous concrete and asphalt concrete both consist of aggregates bound by bitumen, but bituminous concrete typically features a higher binder content, enhancing flexibility and water resistance. Asphalt concrete, widely used in road construction, balances durability and cost-efficiency with a composition optimized for load-bearing and weather resilience. Understanding these differences helps in selecting the right pavement material for specific infrastructure needs.

Composition Differences Between Bituminous and Asphalt Concrete

Bituminous concrete primarily consists of aggregates bonded with bitumen, a viscous black material derived from crude oil, providing flexible and waterproof properties. Asphalt concrete incorporates a similar aggregate composition but uses asphalt cement as a binder, which is more refined and offers enhanced durability and load-bearing capacity. The key compositional difference lies in the binder type and treatment, influencing performance characteristics in paving applications.

Manufacturing Processes of Bituminous vs Asphalt Concrete

Bituminous concrete is manufactured by heating and mixing bitumen binder with aggregates at high temperatures, typically between 150degC and 180degC, ensuring proper coating and adhesion. Asphalt concrete involves a similar process but often includes a wider range of asphalt binder types and may use polymer-modified asphalt for enhanced performance. The choice of bitumen type and mixing temperature directly affects the durability, flexibility, and resistance to deformation in both bituminous and asphalt concrete.

Structural Performance Comparison

Bituminous concrete and asphalt concrete differ primarily in their binder composition, affecting structural performance under varying load conditions. Bituminous concrete, with its higher binder viscosity, offers superior resistance to deformation and is ideal for high-traffic roads requiring enhanced durability. Asphalt concrete provides greater flexibility, allowing better stress distribution and resistance to cracking in fluctuating temperature environments.

Durability and Lifespan Analysis

Bituminous concrete and asphalt concrete differ primarily in binder composition, impacting durability and lifespan. Bituminous concrete, with its higher bitumen content, offers superior flexibility and resistance to cracking under thermal stress, extending pavement life. Asphalt concrete, often stiffer due to added aggregates, provides excellent load-bearing capacity but may experience reduced lifespan in freeze-thaw climates due to brittleness.

Cost Comparison: Bituminous vs Asphalt Concrete

Bituminous concrete typically incurs lower initial costs compared to asphalt concrete due to the use of less refined bitumen and simpler production methods. Asphalt concrete, while more expensive upfront, offers enhanced durability and reduced maintenance expenses over time, which can result in better long-term cost efficiency. Evaluating both materials requires considering project lifespan, traffic load, and regional availability to determine the most cost-effective solution.

Environmental Impact and Sustainability

Bituminous concrete and asphalt concrete differ in environmental impact, with bituminous concrete often containing higher percentages of recycled materials, reducing resource extraction and landfill waste. Asphalt concrete typically offers improved durability and longer service life, which lowers maintenance frequency and associated emissions over time. Both materials support sustainability goals through potential use of warm-mix technologies that reduce energy consumption during production and application.

Applications in Road Construction

Bituminous concrete, composed of bitumen binder and mineral aggregates, is widely used for high-traffic road surfaces due to its durability and smooth finish. Asphalt concrete, a mixture of asphalt binder and aggregate, serves effectively in both flexible pavements and base layers, offering resistance to deformation and water damage. In road construction, bituminous concrete is preferred for top layers, while asphalt concrete often supports sub-base and intermediate layers, optimizing pavement performance.

Maintenance Requirements and Repair Techniques

Bituminous concrete and asphalt concrete differ significantly in maintenance requirements and repair techniques due to their compositional variations; bituminous concrete often requires more frequent surface sealing to prevent oxidation, while asphalt concrete benefits from periodic crack filling and overlay applications. Repair techniques for bituminous concrete typically involve patching with fresh bitumen mixes to restore flexibility, whereas asphalt concrete repairs often use hot mix asphalt to ensure structural integrity and longevity. Both materials demand routine inspections to identify early signs of distress, optimizing lifespan and performance in road construction and paving projects.

Choosing the Right Material: Factors to Consider

Bituminous concrete and asphalt concrete differ primarily in their binder composition, impacting durability and flexibility. When choosing the right material, factors such as traffic load, climate conditions, and project budget should be prioritized, as bituminous concrete offers superior resistance to heavy traffic, while asphalt concrete provides cost-effective performance in milder environments. Proper evaluation of environmental conditions and maintenance requirements ensures optimal pavement longevity and safety.

Bituminous Concrete vs Asphalt Concrete Infographic

materialdif.com

materialdif.com