Asphalt binder and asphalt cement are terms often used interchangeably but have distinct meanings in pavement construction. Asphalt binder refers to the viscous, adhesive substance that binds aggregate particles together, typically modified with additives to enhance performance, while asphalt cement is the unmodified, pure bitumen used as the base material. Understanding the differences is crucial for selecting the appropriate material to ensure durability and flexibility in road surfaces.

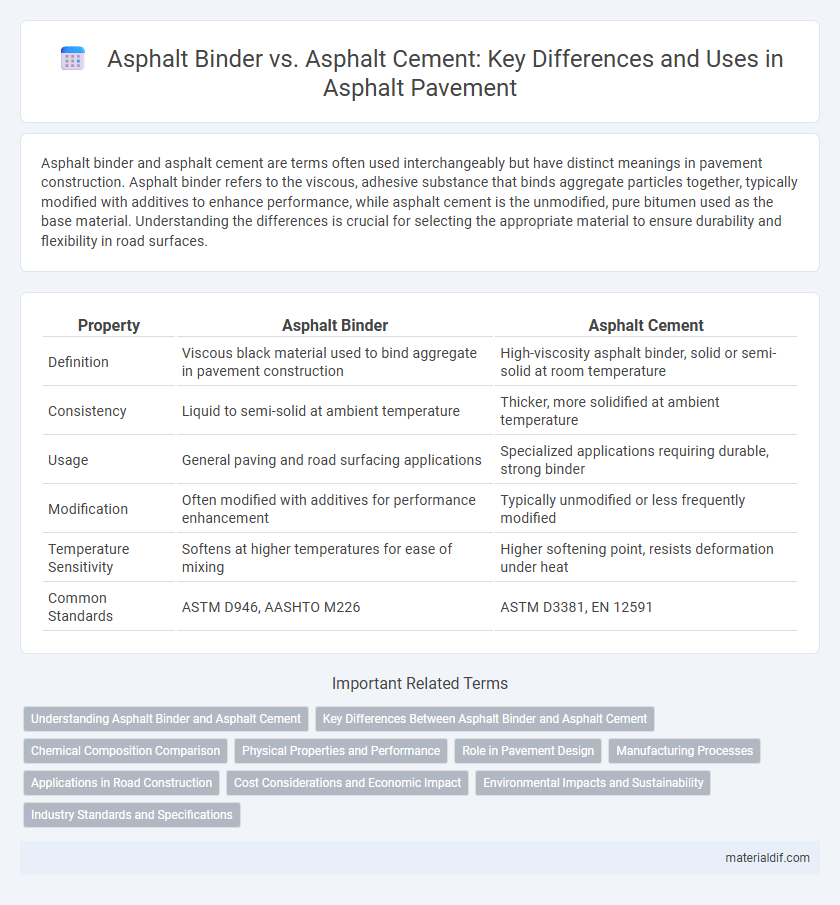

Table of Comparison

| Property | Asphalt Binder | Asphalt Cement |

|---|---|---|

| Definition | Viscous black material used to bind aggregate in pavement construction | High-viscosity asphalt binder, solid or semi-solid at room temperature |

| Consistency | Liquid to semi-solid at ambient temperature | Thicker, more solidified at ambient temperature |

| Usage | General paving and road surfacing applications | Specialized applications requiring durable, strong binder |

| Modification | Often modified with additives for performance enhancement | Typically unmodified or less frequently modified |

| Temperature Sensitivity | Softens at higher temperatures for ease of mixing | Higher softening point, resists deformation under heat |

| Common Standards | ASTM D946, AASHTO M226 | ASTM D3381, EN 12591 |

Understanding Asphalt Binder and Asphalt Cement

Asphalt binder is a petroleum product used to bind aggregate particles in pavement mixtures, providing flexibility and durability under various temperature conditions. Asphalt cement, a specific type of asphalt binder, is characterized by its higher viscosity and is often employed in hot mix asphalt applications for road surfaces. Understanding the distinction between asphalt binder and asphalt cement is crucial for selecting the appropriate material based on project requirements and environmental factors.

Key Differences Between Asphalt Binder and Asphalt Cement

Asphalt binder is a broad term referring to the viscous, black, sticky material used to bind aggregate particles in pavement construction, while asphalt cement specifically denotes the refined product obtained from petroleum refining with defined properties for road surfacing. Asphalt cement possesses higher viscosity and stiffness compared to general asphalt binders, making it more suitable for load-bearing pavement layers. Key differences include their production methods, consistency, and performance characteristics under temperature variations.

Chemical Composition Comparison

Asphalt binder and asphalt cement primarily differ in their chemical composition, with asphalt binder containing additives like polymers and rejuvenators to enhance flexibility and durability, while asphalt cement is composed mainly of bitumen, a complex mixture of hydrocarbons. The chemical structure of asphalt binder includes modified asphaltenes, resins, and oils, which improve performance under temperature variations, contrasting with the relatively unmodified hydrocarbons in asphalt cement. Understanding the specific ratios of saturates, aromatics, resins, and asphaltenes in each material is crucial for selecting the appropriate binder for pavement applications.

Physical Properties and Performance

Asphalt binder and asphalt cement differ primarily in viscosity and temperature susceptibility, with asphalt binder exhibiting modified flexibility and improved resistance to deformation under varying climate conditions. Asphalt cement represents the unmodified, raw petroleum product used in pavement mixtures, characterized by a higher viscosity and stiffness, which affects its performance in load-bearing and thermal cracking resistance. Enhanced physical properties of asphalt binder, such as increased elasticity and better temperature stability, contribute to longer pavement life and superior performance in diverse environmental conditions.

Role in Pavement Design

Asphalt binder is a crucial component in pavement design, acting as the adhesive that binds aggregate particles together to provide flexibility and durability in the pavement structure. Asphalt cement, often referred to as a type of asphalt binder, is a homogeneous black bituminous material specifically used for its waterproofing and cohesive properties. The selection and specification of asphalt binder or asphalt cement directly influence the pavement's performance characteristics, such as resistance to cracking, rutting, and aging under various traffic loads and environmental conditions.

Manufacturing Processes

Asphalt binder and asphalt cement both originate from crude oil refining but differ in their manufacturing processes; asphalt cement is produced by vacuum distillation and air blowing, enhancing its viscoelastic properties for road construction. Asphalt binder involves blending asphalt cement with modifiers such as polymers or fibers to improve performance under various temperature and load conditions. These tailored manufacturing steps ensure asphalt binder meets specific project requirements, offering greater durability and flexibility compared to standard asphalt cement.

Applications in Road Construction

Asphalt binder and asphalt cement are critical materials in road construction, with asphalt binder serving as the adhesive component that binds aggregate particles together, enhancing flexibility and durability in pavement layers. Asphalt cement, a highly viscous form of asphalt binder, is predominantly used in hot mix asphalt production for highways, providing strong resistance to deformation and weathering. Their applications differ by performance requirements: asphalt binder is favored in applications needing improved elasticity for lower traffic roads, while asphalt cement is preferred for high-traffic areas demanding robust load-bearing capacity and longevity.

Cost Considerations and Economic Impact

Asphalt binder, a refined product derived from asphalt cement, typically incurs higher initial costs due to advanced processing and additives enhancing performance. Asphalt cement, a conventional paving material, offers lower upfront expenses but may require more frequent maintenance, impacting long-term economic efficiency. Evaluating lifecycle costs and pavement durability is crucial for making cost-effective infrastructure investment decisions.

Environmental Impacts and Sustainability

Asphalt binder, often modified with additives to enhance performance, generally offers improved durability and reduced maintenance, which can lower the environmental footprint over time compared to traditional asphalt cement. Asphalt cement, a basic petroleum product, tends to have higher emissions during production and application, contributing more to air pollution and resource depletion. Utilizing recycled asphalt binder in pavement mixtures supports sustainability by reducing raw material extraction and minimizing landfill waste.

Industry Standards and Specifications

Asphalt binder and asphalt cement differ primarily in viscosity and performance criteria according to industry standards such as ASTM D946 and AASHTO M226, which specify viscosity and consistency requirements for asphalt cement used in pavement construction. Asphalt binder refers broadly to asphalt cement modified with additives or polymers to enhance properties like elasticity and temperature susceptibility, meeting specifications like PG (Performance Grade) ratings under AASHTO M320. Compliance with these standards ensures durability, workability, and long-term performance in highway and road applications.

Asphalt Binder vs Asphalt Cement Infographic

materialdif.com

materialdif.com