Stone Matrix Asphalt (SMA) features a coarse aggregate structure designed for superior rut resistance and durability, making it ideal for high-traffic roads and heavy loads. Superpave Asphalt incorporates a performance-graded binder and optimized aggregate gradation to enhance pavement performance under varying climate and traffic conditions. While SMA excels in durability and skid resistance, Superpave offers customization for specific environmental stresses and load demands, ensuring longer pavement life.

Table of Comparison

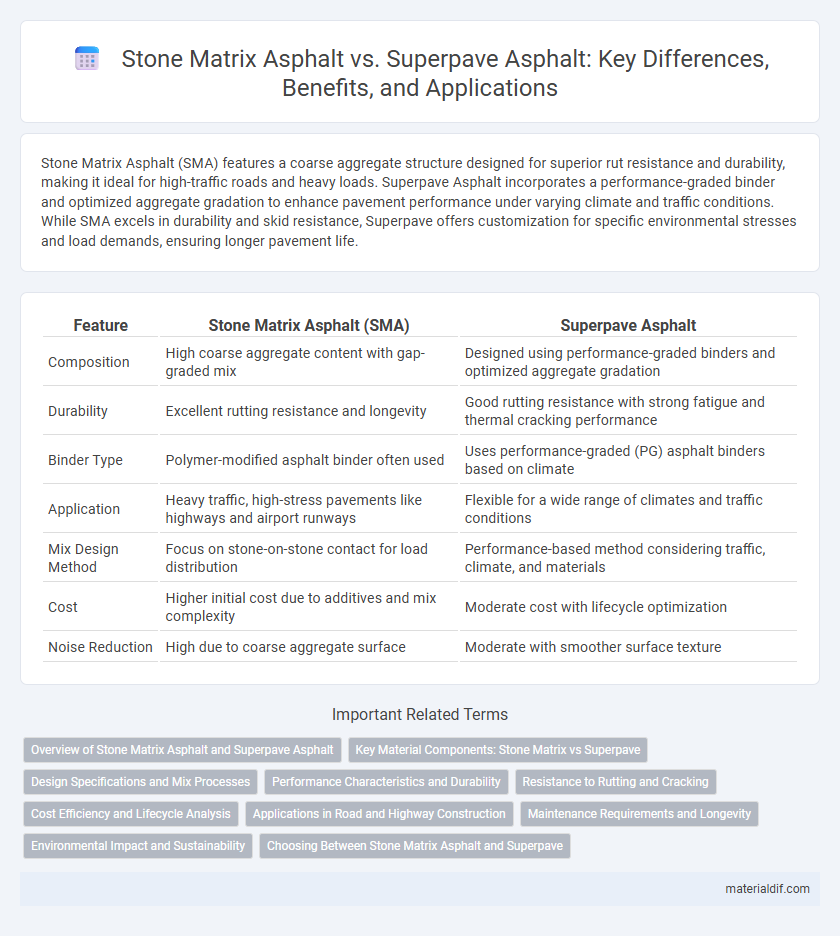

| Feature | Stone Matrix Asphalt (SMA) | Superpave Asphalt |

|---|---|---|

| Composition | High coarse aggregate content with gap-graded mix | Designed using performance-graded binders and optimized aggregate gradation |

| Durability | Excellent rutting resistance and longevity | Good rutting resistance with strong fatigue and thermal cracking performance |

| Binder Type | Polymer-modified asphalt binder often used | Uses performance-graded (PG) asphalt binders based on climate |

| Application | Heavy traffic, high-stress pavements like highways and airport runways | Flexible for a wide range of climates and traffic conditions |

| Mix Design Method | Focus on stone-on-stone contact for load distribution | Performance-based method considering traffic, climate, and materials |

| Cost | Higher initial cost due to additives and mix complexity | Moderate cost with lifecycle optimization |

| Noise Reduction | High due to coarse aggregate surface | Moderate with smoother surface texture |

Overview of Stone Matrix Asphalt and Superpave Asphalt

Stone Matrix Asphalt (SMA) is a gap-graded mixture designed to provide high rut resistance and durability by incorporating a coarse aggregate skeleton with high asphalt content and fiber additives for improved cohesion. Superpave Asphalt, developed through the Strategic Highway Research Program, emphasizes performance-based mix design that tailors asphalt binders and aggregates to specific pavement conditions, focusing on resistance to rutting, fatigue, and low-temperature cracking. Both SMA and Superpave prioritize long-lasting pavements but differ in aggregate gradation and binder specifications to meet distinct performance requirements.

Key Material Components: Stone Matrix vs Superpave

Stone Matrix Asphalt (SMA) incorporates a high content of coarse aggregates and a rich mortar binder enriched with fibers or polymers, which enhances mixture stability and resistance to rutting and deformation. Superpave Asphalt emphasizes a balanced gradation of aggregate sizes combined with performance-graded (PG) asphalt binders tailored to specific climatic conditions, optimizing durability and flexibility. The key material difference lies in SMA's gap-graded aggregate structure for load distribution and Superpave's carefully designed aggregate matrix and binder selection for enhanced performance against temperature and traffic stresses.

Design Specifications and Mix Processes

Stone Matrix Asphalt (SMA) features a high coarse aggregate content with a rich mortar binder, designed for durability and resistance to rutting, using a gap-graded aggregate structure for high stone-on-stone contact. Superpave Asphalt uses the Performance Grade (PG) system to tailor binder and aggregate properties based on traffic load, temperature, and climate conditions, with a focus on volumetric mix design criteria to optimize pavement performance. Both processes emphasize precise temperature control during mixing and compaction to ensure optimal binder coating and minimize moisture damage, but SMA relies more heavily on stabilizing additives like fibers or polymers to maintain mixture cohesion.

Performance Characteristics and Durability

Stone Matrix Asphalt (SMA) exhibits superior rutting resistance and skid resistance due to its high coarse aggregate content and strong stone-on-stone skeleton, making it ideal for heavy traffic conditions. Superpave Asphalt is engineered through performance-based grading of binders and optimized aggregate gradation, providing enhanced fatigue resistance and temperature susceptibility. Both mixtures offer durable pavement solutions, but SMA typically outperforms Superpave in terms of rutting resistance, while Superpave excels in flexibility and cracking resistance under varying climatic conditions.

Resistance to Rutting and Cracking

Stone Matrix Asphalt (SMA) exhibits superior resistance to rutting due to its dense stone-on-stone skeleton and high binder content, which enhances durability under heavy traffic loads. Superpave Asphalt, designed with performance-graded binders, offers improved resistance to cracking by accommodating temperature variations and preventing binder fatigue. While SMA excels in rutting resistance, Superpave delivers balanced performance against both rutting and thermal cracking, making each suitable for different pavement conditions.

Cost Efficiency and Lifecycle Analysis

Stone Matrix Asphalt (SMA) offers superior durability and rut resistance compared to Superpave Asphalt, resulting in lower maintenance costs over the pavement lifecycle. Although SMA typically has higher initial costs due to its polymer-modified binders and fiber additives, the extended service life reduces total expenditure by minimizing repairs and rehabilitation. Lifecycle analysis consistently highlights SMA's cost efficiency in high-traffic applications where long-term performance outweighs upfront investment.

Applications in Road and Highway Construction

Stone Matrix Asphalt (SMA) is widely used in high-traffic highways due to its superior rut resistance and durability, providing long-lasting pavement under heavy loads. Superpave Asphalt, designed through performance-based specifications, excels in adapting to varying climate conditions and traffic stresses, making it suitable for both urban roads and highways with diverse environmental challenges. Both asphalt types enhance pavement performance but SMA is preferred for surface layers requiring enhanced skid resistance, while Superpave is versatile for base and binder layers across different regions.

Maintenance Requirements and Longevity

Stone Matrix Asphalt (SMA) offers superior rut resistance and durability compared to Superpave Asphalt, reducing maintenance frequency and extending pavement life. SMA's high binder content and fiber reinforcement improve moisture damage resistance, resulting in fewer potholes and surface cracks over time. Superpave Asphalt, while cost-effective initially, typically requires more frequent maintenance due to its susceptibility to rutting and fatigue in heavy traffic conditions.

Environmental Impact and Sustainability

Stone Matrix Asphalt (SMA) uses a high stone content and polymer-modified binders that enhance durability and reduce maintenance frequency, leading to lower lifecycle carbon emissions. Superpave Asphalt incorporates performance-graded binders tailored to local climate conditions, optimizing material efficiency and reducing waste during road construction. Both technologies support sustainability, but SMA's robust structure often results in longer pavement life and decreased resource consumption over time.

Choosing Between Stone Matrix Asphalt and Superpave

Stone Matrix Asphalt (SMA) offers superior rut resistance and durability due to its high coarse aggregate content and fiber reinforcement, making it ideal for heavy traffic areas. Superpave Asphalt focuses on performance grading tailored to climate and load conditions, optimizing binder selection for diverse environmental stresses. Selecting between SMA and Superpave depends on project demands: SMA suits high-load, rut-prone pavements, while Superpave offers versatile performance for varying temperatures and traffic volumes.

Stone Matrix Asphalt vs Superpave Asphalt Infographic

materialdif.com

materialdif.com