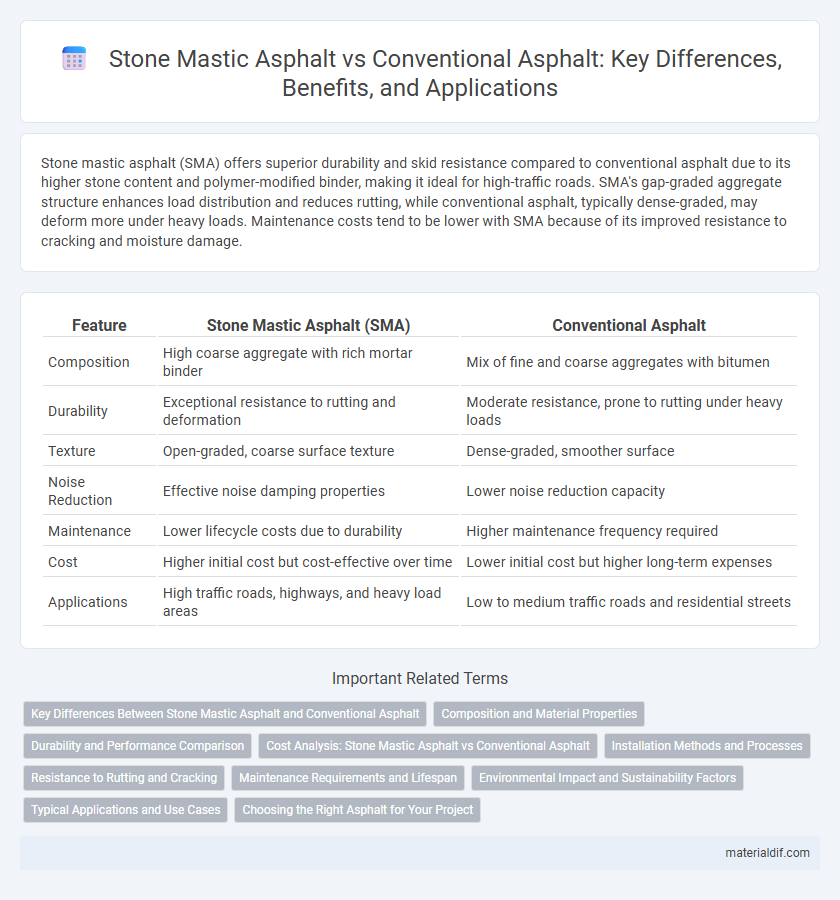

Stone mastic asphalt (SMA) offers superior durability and skid resistance compared to conventional asphalt due to its higher stone content and polymer-modified binder, making it ideal for high-traffic roads. SMA's gap-graded aggregate structure enhances load distribution and reduces rutting, while conventional asphalt, typically dense-graded, may deform more under heavy loads. Maintenance costs tend to be lower with SMA because of its improved resistance to cracking and moisture damage.

Table of Comparison

| Feature | Stone Mastic Asphalt (SMA) | Conventional Asphalt |

|---|---|---|

| Composition | High coarse aggregate with rich mortar binder | Mix of fine and coarse aggregates with bitumen |

| Durability | Exceptional resistance to rutting and deformation | Moderate resistance, prone to rutting under heavy loads |

| Texture | Open-graded, coarse surface texture | Dense-graded, smoother surface |

| Noise Reduction | Effective noise damping properties | Lower noise reduction capacity |

| Maintenance | Lower lifecycle costs due to durability | Higher maintenance frequency required |

| Cost | Higher initial cost but cost-effective over time | Lower initial cost but higher long-term expenses |

| Applications | High traffic roads, highways, and heavy load areas | Low to medium traffic roads and residential streets |

Key Differences Between Stone Mastic Asphalt and Conventional Asphalt

Stone mastic asphalt (SMA) features a gap-graded aggregate structure that provides high rut resistance and durability, unlike conventional asphalt which typically uses a dense-graded mix. SMA contains a higher binder content and cellulose fibers that enhance its deformation resistance and reduce binder drain-off, improving longevity under heavy traffic loads. Conventional asphalt generally offers easier compaction and lower initial costs but lacks the superior surface texture and rutting resistance characteristic of SMA.

Composition and Material Properties

Stone mastic asphalt (SMA) contains a higher percentage of coarse aggregate and modified binder, providing enhanced rut resistance and durability compared to conventional asphalt. Conventional asphalt uses a more uniform aggregate gradation with a lower binder modifier content, resulting in different deformation characteristics and lower resistance to heavy traffic loads. The gap-graded structure of SMA ensures a stone-on-stone skeleton that improves load distribution and reduces binder drain-off, making it suitable for high-stress pavement applications.

Durability and Performance Comparison

Stone mastic asphalt (SMA) exhibits superior durability compared to conventional asphalt due to its high stone content and strong binder-rich mastic, which enhances resistance to rutting and cracking under heavy traffic loads. The gap-graded structure of SMA provides excellent skid resistance and longer lifespan, significantly reducing maintenance costs and frequency. Conventional asphalt, while cost-effective initially, tends to deteriorate faster under environmental stress and high traffic, making SMA the preferred choice for high-performance pavement applications.

Cost Analysis: Stone Mastic Asphalt vs Conventional Asphalt

Stone Mastic Asphalt (SMA) typically incurs higher initial material and installation costs compared to Conventional Asphalt due to its specialized mix of coarse aggregates and fiber additives. However, SMA demonstrates superior durability and rut resistance, resulting in lower maintenance and lifecycle expenses over time. Cost analysis often shows that while Conventional Asphalt may be cheaper upfront, SMA provides better long-term value for heavy traffic roads due to reduced rehabilitation frequency and extended pavement lifespan.

Installation Methods and Processes

Stone mastic asphalt (SMA) requires specialized installation methods involving high-quality binder mastics and optimized aggregate gradation to ensure durability and resistance to deformation. Conventional asphalt installation typically uses a standard mix with lower binder content and simpler compaction processes, making it easier and faster to apply but less resistant to rutting and cracking under heavy traffic. SMA installation demands precise temperature control and enhanced compaction techniques to achieve the optimal void structure and load-bearing capacity.

Resistance to Rutting and Cracking

Stone mastic asphalt (SMA) offers superior resistance to rutting and cracking compared to conventional asphalt due to its dense framework of coarse aggregates bound by a rich mastic binder. The high stone content in SMA creates a strong skeleton that withstands heavy traffic loads and thermal stresses, reducing deformation and surface wear. Conventional asphalt, with a lower aggregate interlock and higher binder content, is more prone to rutting under repetitive loading and cracking from temperature fluctuations.

Maintenance Requirements and Lifespan

Stone mastic asphalt (SMA) offers superior durability and requires less frequent maintenance compared to conventional asphalt due to its high stone content and binder-rich mastic that resists rutting and cracking. Conventional asphalt tends to deteriorate faster under heavy traffic and extreme weather, leading to more frequent repairs and shorter lifespans typically around 8-12 years, while SMA can last 15-20 years with minimal maintenance. The enhanced mechanical stability and resistance of SMA reduce lifecycle costs and extend pavement performance in demanding environments.

Environmental Impact and Sustainability Factors

Stone mastic asphalt (SMA) offers enhanced durability and reduces the frequency of repairs compared to conventional asphalt, minimizing material consumption and lowering carbon emissions over its lifecycle. Its higher binder content and stone skeleton structure improve resistance to deformation and rutting, extending pavement lifespan and supporting sustainability goals. Conventional asphalt requires more frequent maintenance, increasing resource use and environmental footprint, whereas SMA's longevity contributes to reduced environmental impacts and better sustainable road infrastructure.

Typical Applications and Use Cases

Stone Mastic Asphalt (SMA) is commonly used in high-traffic areas such as highways, airport runways, and urban roads requiring enhanced durability and skid resistance. Conventional asphalt suits general road construction, residential streets, and light traffic zones where cost-effectiveness and ease of application are priorities. SMA's coarse aggregate structure provides superior rutting resistance, making it ideal for heavy-load pavements, unlike conventional asphalt which is more prone to deformation under similar conditions.

Choosing the Right Asphalt for Your Project

Stone mastic asphalt (SMA) offers superior durability and rut resistance compared to conventional asphalt, making it ideal for high-traffic roads and heavy load conditions. Conventional asphalt provides a cost-effective solution for low to moderate traffic areas but may require more frequent maintenance. Selecting the right asphalt depends on traffic volume, load intensity, and project budget to ensure long-term performance and cost-efficiency.

Stone mastic asphalt vs Conventional asphalt Infographic

materialdif.com

materialdif.com