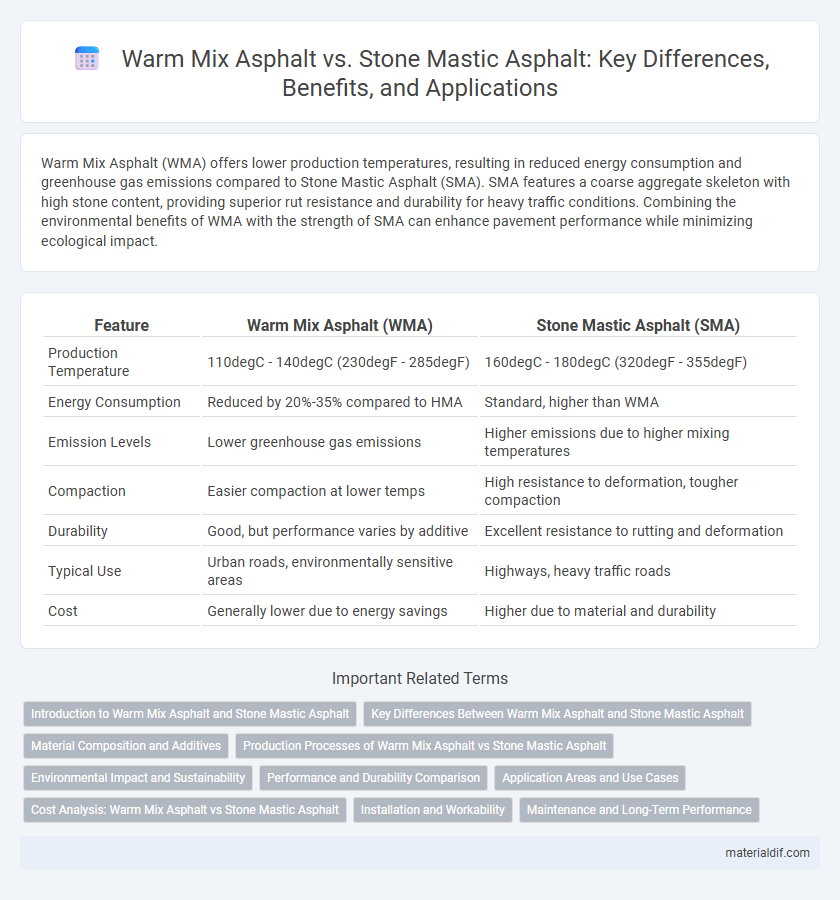

Warm Mix Asphalt (WMA) offers lower production temperatures, resulting in reduced energy consumption and greenhouse gas emissions compared to Stone Mastic Asphalt (SMA). SMA features a coarse aggregate skeleton with high stone content, providing superior rut resistance and durability for heavy traffic conditions. Combining the environmental benefits of WMA with the strength of SMA can enhance pavement performance while minimizing ecological impact.

Table of Comparison

| Feature | Warm Mix Asphalt (WMA) | Stone Mastic Asphalt (SMA) |

|---|---|---|

| Production Temperature | 110degC - 140degC (230degF - 285degF) | 160degC - 180degC (320degF - 355degF) |

| Energy Consumption | Reduced by 20%-35% compared to HMA | Standard, higher than WMA |

| Emission Levels | Lower greenhouse gas emissions | Higher emissions due to higher mixing temperatures |

| Compaction | Easier compaction at lower temps | High resistance to deformation, tougher compaction |

| Durability | Good, but performance varies by additive | Excellent resistance to rutting and deformation |

| Typical Use | Urban roads, environmentally sensitive areas | Highways, heavy traffic roads |

| Cost | Generally lower due to energy savings | Higher due to material and durability |

Introduction to Warm Mix Asphalt and Stone Mastic Asphalt

Warm Mix Asphalt (WMA) is produced at lower temperatures compared to traditional hot mix asphalt, reducing energy consumption and emissions while improving workability. Stone Mastic Asphalt (SMA) features a gap-graded aggregate structure with high binder content, providing superior rut resistance and durability for heavy traffic. Both materials offer distinct advantages in pavement performance and environmental impact, with WMA emphasizing sustainability and SMA focusing on enhanced mechanical strength.

Key Differences Between Warm Mix Asphalt and Stone Mastic Asphalt

Warm Mix Asphalt (WMA) is produced at lower temperatures, reducing energy consumption and emissions compared to Stone Mastic Asphalt (SMA), which is hot-mixed for enhanced durability. SMA features a gap-graded aggregate structure combined with high asphalt binder content and fibers, providing superior rut resistance and skid resistance ideal for high-traffic roads. WMA offers environmental advantages and ease of compaction, while SMA delivers exceptional mechanical performance and longevity under heavy load conditions.

Material Composition and Additives

Warm Mix Asphalt (WMA) utilizes lower temperatures by incorporating organic additives, chemical additives, or water-based foaming agents, which improve workability and reduce emissions compared to traditional hot mixes. Stone Mastic Asphalt (SMA) features a high proportion of coarse aggregates bound with a rich mortar of bitumen and filler, enhanced by fibers or stabilizers to prevent binder drain down and increase rutting resistance. The material composition of WMA emphasizes modified binders and additives for temperature reduction, while SMA relies on aggregate gradation and binder-rich mastic for durability and load-bearing capacity.

Production Processes of Warm Mix Asphalt vs Stone Mastic Asphalt

Warm Mix Asphalt (WMA) production involves lowering the asphalt binder temperature by 20-40degC using additives or foaming techniques, significantly reducing energy consumption and emissions. Stone Mastic Asphalt (SMA) production maintains traditional high temperatures around 150-170degC, ensuring a coarse aggregate skeleton for enhanced rut resistance. The WMA process emphasizes environmental efficiency, while SMA prioritizes durability and load-bearing capacity.

Environmental Impact and Sustainability

Warm Mix Asphalt (WMA) reduces greenhouse gas emissions by lowering production temperatures, resulting in energy savings of up to 30% compared to traditional methods. Stone Mastic Asphalt (SMA) offers increased durability and longer lifespan, reducing the frequency of repairs and associated environmental disturbances. Combining WMA production techniques with SMA's robust composition enhances sustainability by minimizing carbon footprint and resource consumption over the pavement lifecycle.

Performance and Durability Comparison

Warm Mix Asphalt (WMA) offers enhanced workability and lower production temperatures, resulting in reduced energy consumption and emissions, but its long-term durability may be slightly lower in extreme load conditions compared to Stone Mastic Asphalt (SMA). SMA features a robust stone-on-stone skeleton with high binder content, providing superior rut resistance, skid resistance, and overall durability under heavy traffic loads. Performance evaluation indicates that while WMA supports sustainable construction goals, SMA remains the preferred choice for high-stress pavements due to its exceptional resistance to deformation and aging.

Application Areas and Use Cases

Warm Mix Asphalt is preferred for urban road reconstruction and rehabilitation projects due to its lower production temperatures, which reduce greenhouse gas emissions and improve worker safety. Stone Mastic Asphalt is commonly used on high-traffic highways and heavy-load industrial pavements because of its superior rutting resistance and durability. Both materials are applicable in surface dressing and maintenance, with Warm Mix Asphalt favored for climate-sensitive environments and Stone Mastic Asphalt for long-life pavement solutions.

Cost Analysis: Warm Mix Asphalt vs Stone Mastic Asphalt

Warm Mix Asphalt (WMA) offers significant cost savings compared to Stone Mastic Asphalt (SMA) due to lower production temperatures, resulting in reduced fuel consumption and greenhouse gas emissions. SMA, while more expensive upfront due to higher binder content and complex mixing processes, provides superior durability and skid resistance, potentially lowering long-term maintenance expenses. Evaluating lifecycle costs reveals WMA's advantages in initial installation, whereas SMA's higher durability may justify its premium in high-traffic applications.

Installation and Workability

Warm Mix Asphalt (WMA) allows for lower production temperatures, enhancing workability by reducing viscosity and improving compaction ease, which results in faster installation and lower energy consumption. Stone Mastic Asphalt (SMA) features a coarse aggregate skeleton and a rich mastic binder, offering high resistance to rutting and deformation but requires careful handling and higher compaction effort during installation. While WMA improves placement efficiency and reduces emissions, SMA excels in durability and load distribution, making the choice dependent on project-specific performance and environmental goals.

Maintenance and Long-Term Performance

Warm Mix Asphalt (WMA) offers easier maintenance due to its lower production temperatures, reducing aging and cracking over time. Stone Mastic Asphalt (SMA) provides superior long-term performance with enhanced rut resistance and durability, making it ideal for high-traffic areas. While WMA supports environmental sustainability and faster repairs, SMA excels in structural strength and lifespan, minimizing frequent maintenance needs.

Warm Mix Asphalt vs Stone Mastic Asphalt Infographic

materialdif.com

materialdif.com