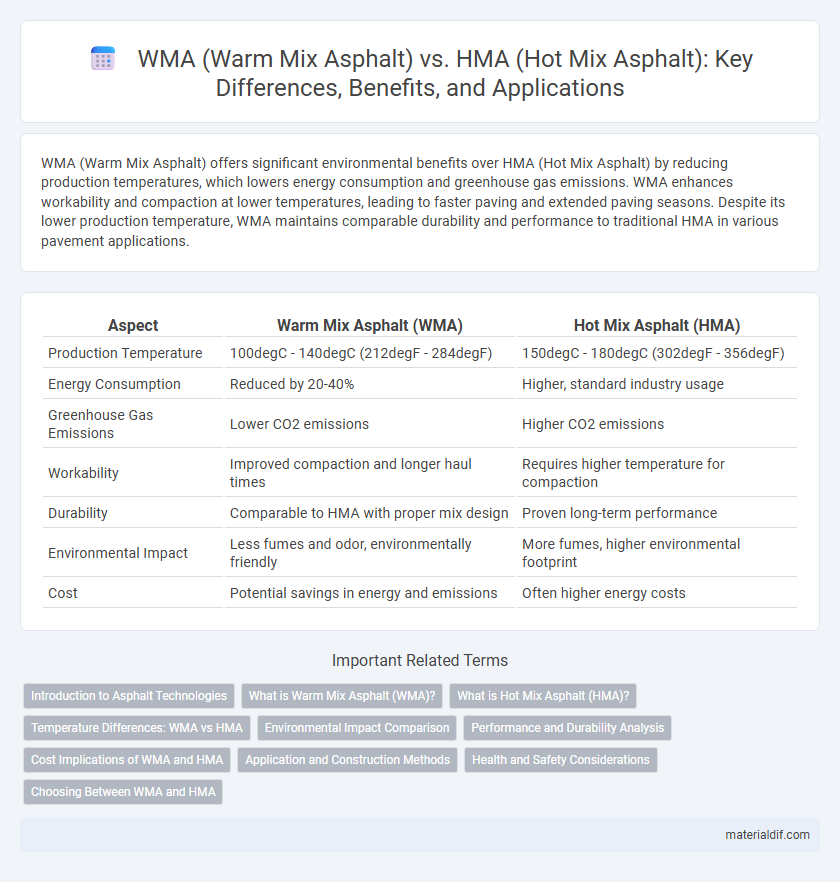

WMA (Warm Mix Asphalt) offers significant environmental benefits over HMA (Hot Mix Asphalt) by reducing production temperatures, which lowers energy consumption and greenhouse gas emissions. WMA enhances workability and compaction at lower temperatures, leading to faster paving and extended paving seasons. Despite its lower production temperature, WMA maintains comparable durability and performance to traditional HMA in various pavement applications.

Table of Comparison

| Aspect | Warm Mix Asphalt (WMA) | Hot Mix Asphalt (HMA) |

|---|---|---|

| Production Temperature | 100degC - 140degC (212degF - 284degF) | 150degC - 180degC (302degF - 356degF) |

| Energy Consumption | Reduced by 20-40% | Higher, standard industry usage |

| Greenhouse Gas Emissions | Lower CO2 emissions | Higher CO2 emissions |

| Workability | Improved compaction and longer haul times | Requires higher temperature for compaction |

| Durability | Comparable to HMA with proper mix design | Proven long-term performance |

| Environmental Impact | Less fumes and odor, environmentally friendly | More fumes, higher environmental footprint |

| Cost | Potential savings in energy and emissions | Often higher energy costs |

Introduction to Asphalt Technologies

Warm Mix Asphalt (WMA) and Hot Mix Asphalt (HMA) represent two primary asphalt technologies used in road construction, with WMA produced at temperatures 20-40degC lower than HMA, reducing energy consumption and emissions. WMA incorporates additives or water to enhance workability at lower temperatures, improving compaction and extending paving seasons. HMA remains preferred for its long-standing durability and established performance in high-traffic areas, but WMA's environmental benefits and cost savings are driving increased adoption worldwide.

What is Warm Mix Asphalt (WMA)?

Warm Mix Asphalt (WMA) is produced and applied at temperatures between 20degC to 40degC lower than Hot Mix Asphalt (HMA), typically around 100degC to 140degC. This temperature reduction lowers energy consumption and decreases greenhouse gas emissions during production, enabling a more sustainable paving process. WMA incorporates additives or foaming techniques that improve workability and compaction at these cooler temperatures without compromising pavement performance.

What is Hot Mix Asphalt (HMA)?

Hot Mix Asphalt (HMA) is a traditional asphalt mixture produced by heating aggregate and asphalt binder to high temperatures, typically between 275degF and 325degF, to achieve proper coating and workability. This process allows HMA to be laid and compacted while hot, creating a durable and strong pavement surface commonly used in highways, roads, and airports. The high-temperature production of HMA results in increased energy consumption and higher emissions compared to Warm Mix Asphalt (WMA) alternatives.

Temperature Differences: WMA vs HMA

Warm Mix Asphalt (WMA) is produced and applied at temperatures ranging from 100degC to 140degC, significantly lower than Hot Mix Asphalt (HMA), which is typically mixed and laid between 150degC and 190degC. The reduced temperature in WMA production leads to lower energy consumption and decreased greenhouse gas emissions compared to HMA. This temperature difference also improves worker safety and extends paving season in cooler climates without compromising pavement performance.

Environmental Impact Comparison

Warm Mix Asphalt (WMA) reduces greenhouse gas emissions by up to 30% compared to Hot Mix Asphalt (HMA) due to lower production temperatures, which also decreases energy consumption significantly. WMA production emits fewer volatile organic compounds (VOCs) and particulate matter, contributing to improved air quality during paving operations. In contrast, HMA involves higher fossil fuel use and greater carbon dioxide (CO2) emissions, intensifying its environmental footprint.

Performance and Durability Analysis

Warm Mix Asphalt (WMA) demonstrates comparable performance and durability to Hot Mix Asphalt (HMA) in terms of rutting resistance and fatigue life, with WMA mixtures exhibiting improved workability at lower temperatures. Laboratory and field tests indicate that WMA can achieve similar or enhanced compaction, reducing aging and oxidative hardening, which contributes to longer pavement life. Despite slightly lower stiffness in some cases, WMA's reduced production temperature minimizes thermal cracking, enhancing overall pavement durability under diverse load conditions.

Cost Implications of WMA and HMA

Warm Mix Asphalt (WMA) reduces energy consumption by requiring lower production temperatures compared to Hot Mix Asphalt (HMA), leading to significant savings on fuel costs. Initial WMA material costs may be slightly higher due to additive use, but overall project expenses often decrease due to faster paving times and reduced wear on equipment. Lifecycle maintenance costs for WMA tend to be lower, as its improved compaction properties increase pavement durability and reduce long-term repair needs.

Application and Construction Methods

Warm Mix Asphalt (WMA) applications are favored for projects requiring lower temperature paving, reducing fuel consumption and emissions during construction compared to Hot Mix Asphalt (HMA). WMA allows extended hauling distances and longer paving seasons due to its reduced cooling rate, enhancing workability in cooler climates, while HMA demands higher temperatures and rapid placement to prevent premature cooling. Construction methods for WMA often involve the addition of organic additives, chemical additives, or water foaming techniques to lower viscosity, contrasting with the traditional heating-only approach used in HMA production and placement.

Health and Safety Considerations

Warm Mix Asphalt (WMA) significantly reduces worker exposure to harmful fumes compared to Hot Mix Asphalt (HMA), as WMA is produced at temperatures 20-40degC lower, decreasing emissions of volatile organic compounds (VOCs) and polycyclic aromatic hydrocarbons (PAHs). The lower production temperature of WMA minimizes the risk of burns and heat-related illnesses among workers, enhancing overall onsite safety. Studies indicate that adopting WMA technology leads to improved air quality and reduced respiratory hazards in paving operations.

Choosing Between WMA and HMA

Choosing between Warm Mix Asphalt (WMA) and Hot Mix Asphalt (HMA) depends on project-specific factors such as temperature requirements, environmental impact, and cost efficiency. WMA offers lower production temperatures reducing fuel consumption and emissions, making it ideal for environmentally sensitive areas and extended paving seasons. HMA provides higher durability and is preferable for heavy traffic loads and high-performance applications where long-term strength is critical.

WMA (Warm Mix Asphalt) vs HMA (Hot Mix Asphalt) Infographic

materialdif.com

materialdif.com