Polymer-modified asphalt incorporates synthetic polymers that enhance flexibility, durability, and resistance to temperature extremes compared to conventional asphalt. This modification reduces cracking and rutting, extending pavement lifespan and improving overall performance under heavy traffic loads. Choosing polymer-modified asphalt results in lower maintenance costs and enhanced road safety over time.

Table of Comparison

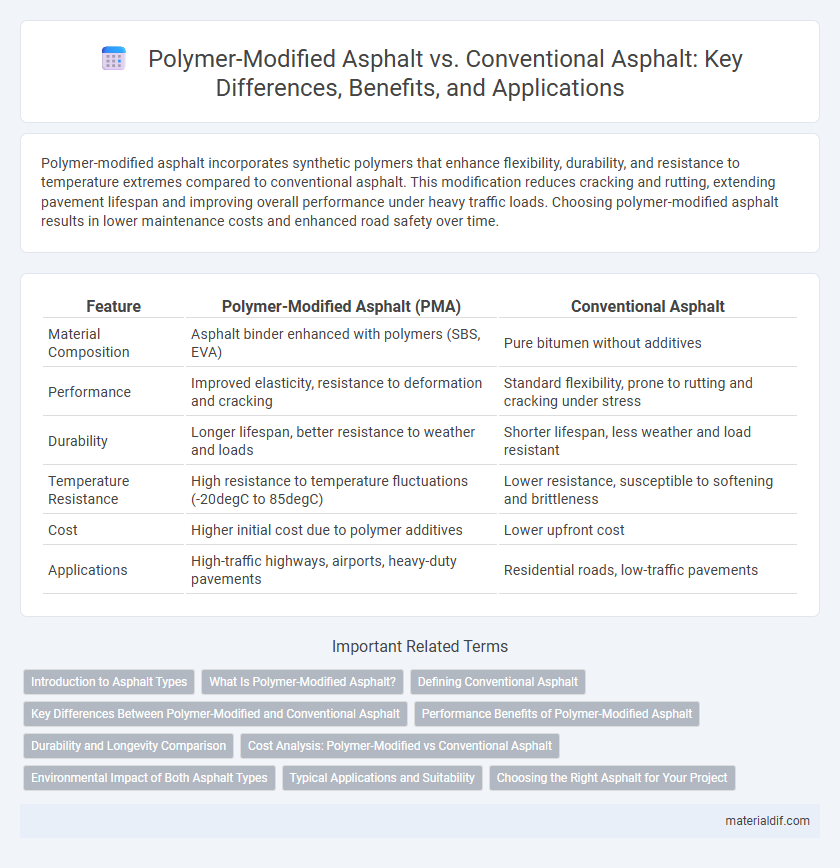

| Feature | Polymer-Modified Asphalt (PMA) | Conventional Asphalt |

|---|---|---|

| Material Composition | Asphalt binder enhanced with polymers (SBS, EVA) | Pure bitumen without additives |

| Performance | Improved elasticity, resistance to deformation and cracking | Standard flexibility, prone to rutting and cracking under stress |

| Durability | Longer lifespan, better resistance to weather and loads | Shorter lifespan, less weather and load resistant |

| Temperature Resistance | High resistance to temperature fluctuations (-20degC to 85degC) | Lower resistance, susceptible to softening and brittleness |

| Cost | Higher initial cost due to polymer additives | Lower upfront cost |

| Applications | High-traffic highways, airports, heavy-duty pavements | Residential roads, low-traffic pavements |

Introduction to Asphalt Types

Polymer-modified asphalt incorporates polymers such as styrene-butadiene-styrene (SBS) to enhance elasticity, durability, and resistance to rutting compared to conventional asphalt. Conventional asphalt, composed primarily of bitumen and aggregates, provides basic pavement performance but tends to be more susceptible to temperature extremes and deformation. The introduction of polymer additives significantly improves the mechanical properties and longevity of asphalt pavements in high-traffic or extreme weather conditions.

What Is Polymer-Modified Asphalt?

Polymer-modified asphalt (PMA) is a blend of conventional asphalt and specialized polymers, such as styrene-butadiene-styrene (SBS) or ethylene-vinyl acetate (EVA), designed to enhance pavement performance. This modification improves key properties like elasticity, temperature resistance, and durability, making PMA highly effective in reducing cracking and rutting under heavy traffic and extreme weather conditions. Compared to conventional asphalt, polymer-modified variants offer superior adhesion, flexibility, and prolonged lifespan in road construction and repair applications.

Defining Conventional Asphalt

Conventional asphalt, also known as hot mix asphalt (HMA), consists primarily of aggregates bound by a bitumen binder without any chemical additives. It provides a flexible pavement solution widely used in road construction due to its cost-effectiveness and ease of production. However, conventional asphalt often exhibits lower resistance to rutting, cracking, and weather-induced damage compared to polymer-modified asphalt.

Key Differences Between Polymer-Modified and Conventional Asphalt

Polymer-modified asphalt incorporates polymers like styrene-butadiene-styrene (SBS) or crumb rubber to enhance flexibility, durability, and resistance to deformation compared to conventional asphalt. This modification significantly improves resistance to cracking, rutting, and temperature fluctuations, resulting in longer pavement life and reduced maintenance costs. Conventional asphalt, primarily made from bitumen and aggregate, tends to be less resilient under heavy traffic loads and extreme weather conditions.

Performance Benefits of Polymer-Modified Asphalt

Polymer-modified asphalt significantly outperforms conventional asphalt by enhancing elasticity, resistance to deformation, and durability under extreme temperature variations. Its improved adhesion properties reduce cracking and rutting, leading to longer pavement lifespan and lower maintenance costs. Studies show polymer modification increases fatigue resistance by up to 50%, making it ideal for high-traffic roadways and extreme environmental conditions.

Durability and Longevity Comparison

Polymer-modified asphalt exhibits superior durability and longevity compared to conventional asphalt due to enhanced resistance to cracking, rutting, and thermal degradation. The addition of polymers improves the binder's elasticity and adhesion, significantly extending pavement life under heavy traffic and extreme weather conditions. Studies show polymer-modified asphalt can last up to 50% longer, reducing maintenance costs and improving long-term performance.

Cost Analysis: Polymer-Modified vs Conventional Asphalt

Polymer-modified asphalt generally incurs higher initial costs compared to conventional asphalt due to the added expense of polymers and manufacturing processes. Long-term cost benefits include enhanced durability, reduced maintenance frequency, and improved resistance to cracking and rutting, which lower overall lifecycle expenses. Studies show that although upfront investment is greater, polymer-modified asphalt can reduce total pavement costs by up to 20% over conventional asphalt in heavy traffic applications.

Environmental Impact of Both Asphalt Types

Polymer-modified asphalt reduces environmental impact by enhancing durability and extending pavement lifespan, which decreases the frequency of repairs and material consumption. Conventional asphalt typically requires more frequent maintenance, leading to higher emissions from production and construction processes. The improved resistance of polymer-modified asphalt to temperature fluctuations and cracking also minimizes resource use and waste generation over time.

Typical Applications and Suitability

Polymer-modified asphalt (PMA) is typically used in high-traffic areas, airport runways, and regions experiencing extreme weather due to its enhanced flexibility and resistance to cracking, making it more suitable for heavy loads and thermal stresses. Conventional asphalt is commonly applied in residential roads, low-traffic streets, and parking lots where cost-efficiency is prioritized and extreme durability is less critical. PMA's improved performance extends pavement life and reduces maintenance needs, while conventional asphalt offers a more economical solution for lighter applications.

Choosing the Right Asphalt for Your Project

Polymer-modified asphalt offers enhanced durability, increased resistance to cracking, and improved flexibility compared to conventional asphalt, making it ideal for high-traffic roads and extreme weather conditions. Conventional asphalt remains a cost-effective choice for low-traffic areas and projects with budget constraints, providing reliable performance with standard maintenance. Selecting the right asphalt requires assessing project requirements, traffic load, climate, and long-term maintenance goals to optimize pavement lifespan and performance.

Polymer-Modified Asphalt vs Conventional Asphalt Infographic

materialdif.com

materialdif.com