Asphalt concrete consists of a mixture of aggregate particles bound together by bitumen, providing a durable and flexible surface ideal for high-traffic roads. Tar-bound macadam uses tar as a binder instead of bitumen, which makes it less resistant to oil and gasoline, leading to faster deterioration. Asphalt concrete offers superior performance in terms of longevity, load-bearing capacity, and weather resistance compared to tar-bound macadam.

Table of Comparison

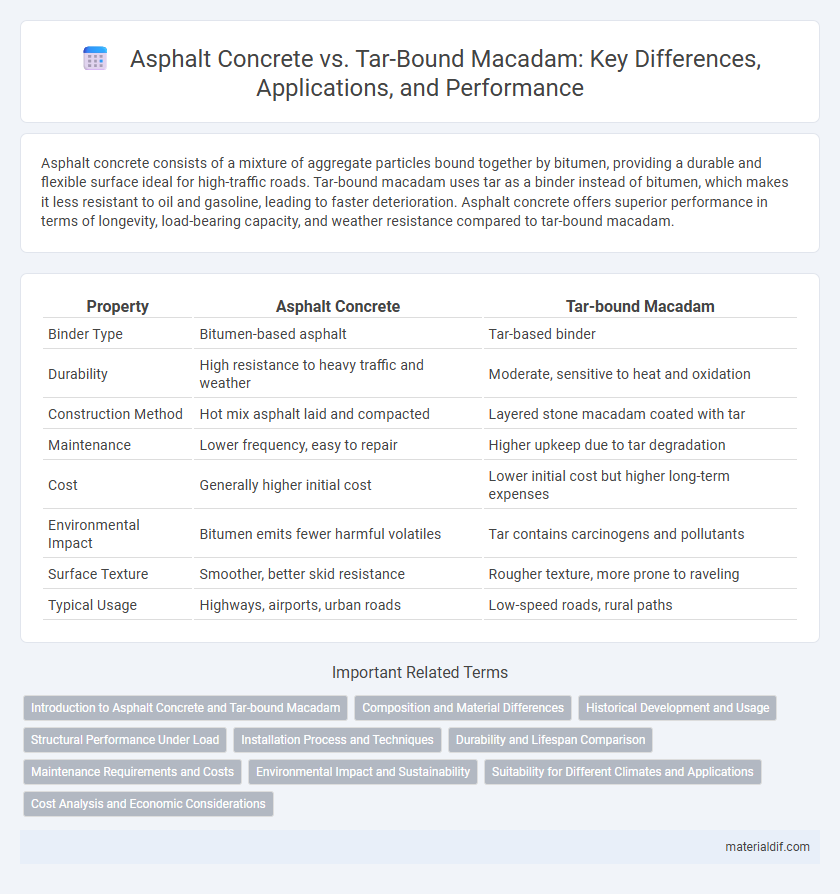

| Property | Asphalt Concrete | Tar-bound Macadam |

|---|---|---|

| Binder Type | Bitumen-based asphalt | Tar-based binder |

| Durability | High resistance to heavy traffic and weather | Moderate, sensitive to heat and oxidation |

| Construction Method | Hot mix asphalt laid and compacted | Layered stone macadam coated with tar |

| Maintenance | Lower frequency, easy to repair | Higher upkeep due to tar degradation |

| Cost | Generally higher initial cost | Lower initial cost but higher long-term expenses |

| Environmental Impact | Bitumen emits fewer harmful volatiles | Tar contains carcinogens and pollutants |

| Surface Texture | Smoother, better skid resistance | Rougher texture, more prone to raveling |

| Typical Usage | Highways, airports, urban roads | Low-speed roads, rural paths |

Introduction to Asphalt Concrete and Tar-bound Macadam

Asphalt concrete is a composite material composed of mineral aggregate bound together with asphalt cement, widely used for road construction due to its durability and flexibility. Tar-bound macadam, known as tar macadam or tarmac, utilizes tar as a binder to coat aggregates, providing a smooth, waterproof surface primarily used in older roadways and pedestrian paths. Both materials serve as essential paving solutions, but asphalt concrete has largely replaced tar-bound macadam due to improved performance and environmental considerations.

Composition and Material Differences

Asphalt Concrete consists of a mixture of aggregates such as sand, gravel, or crushed stone bound together with asphalt cement, providing high durability and flexibility. In contrast, Tar-bound Macadam uses tar as the binder instead of asphalt cement, combined with smaller aggregate sizes, resulting in a less flexible surface prone to cracking. The material difference between bitumen-based Asphalt Concrete and coal-tar-based Tar-bound Macadam directly impacts their resistance to weathering and load-bearing capacity.

Historical Development and Usage

Asphalt concrete, developed in the early 20th century, revolutionized road construction with its durable mixture of aggregates and bitumen, offering superior load-bearing capacity and weather resistance compared to tar-bound macadam, which originated in the 19th century using tar to bind stone layers. The shift from tar-bound macadam to asphalt concrete was driven by advancements in bitumen refining and a growing demand for smoother, longer-lasting road surfaces in urban infrastructure. Asphalt concrete remains the dominant material in modern pavement engineering due to its enhanced flexibility and resistance to rutting and cracking under heavy traffic conditions.

Structural Performance Under Load

Asphalt concrete exhibits superior structural performance under load due to its dense, interlocking aggregate matrix bound by bitumen, enabling it to withstand heavy traffic and dynamic stresses with minimal deformation. Tar-bound macadam, relying on tar as a binder with loosely packed aggregates, tends to have lower load-bearing capacity and is more susceptible to cracking and rutting under repeated loads. The enhanced durability and stability of asphalt concrete make it the preferred material for high-traffic roadways and infrastructure requiring long-term resilience.

Installation Process and Techniques

Asphalt concrete installation involves precise heating, mixing, and paving of bitumen with aggregates, requiring specialized machinery like asphalt pavers and rollers to ensure a smooth, durable surface. Tar-bound macadam employs a manual layering process where tar acts as a binder for crushed stone, often compacted using pneumatic or steel rollers but lacking the uniform density achieved by modern asphalt. The asphalt concrete technique offers superior control over temperature and compaction, resulting in enhanced longevity and resistance to cracking compared to the tar-bound macadam method.

Durability and Lifespan Comparison

Asphalt concrete offers superior durability compared to tar-bound macadam due to its dense, well-compacted aggregate structure and the use of bitumen as a binder, which resists weathering and deformation. The typical lifespan of asphalt concrete ranges from 15 to 30 years under normal traffic conditions, while tar-bound macadam generally lasts between 10 to 20 years, being more susceptible to oxidation and cracking. Modern asphalt concrete's enhanced resistance to water infiltration and heavy loads contributes to its longer service life and reduced maintenance costs.

Maintenance Requirements and Costs

Asphalt concrete requires less frequent maintenance and offers lower long-term costs compared to tar-bound macadam, which is prone to cracking and surface degradation. Asphalt concrete's durability reduces the need for frequent resurfacing, while tar-bound macadam demands regular sealing to maintain structural integrity. Cost analysis reveals that asphalt concrete's initial investment is higher but results in savings due to fewer repairs and extended pavement life.

Environmental Impact and Sustainability

Asphalt concrete demonstrates lower environmental impact compared to tar-bound macadam due to the use of petroleum-based bitumen, which offers better recyclability and reduced toxic emissions during production and application. Tar-bound macadam relies on coal tar, a known carcinogenic substance contributing to higher air pollution and long-term soil contamination risks, making it less sustainable. Modern asphalt concrete technologies enhance sustainability by integrating recycled materials and employing warm-mix processes that reduce energy consumption and carbon footprint.

Suitability for Different Climates and Applications

Asphalt concrete offers superior durability and resistance to temperature fluctuations, making it ideal for a wide range of climates, from hot summers to freezing winters. Tar-bound macadam is better suited for lower-traffic areas and milder climates due to its lower resistance to water and temperature-related wear. The choice between asphalt concrete and tar-bound macadam depends on specific application requirements such as load capacity, environmental exposure, and maintenance considerations.

Cost Analysis and Economic Considerations

Asphalt concrete typically incurs higher initial installation costs compared to tar-bound macadam due to advanced materials and more complex laying processes. However, asphalt concrete offers greater durability and lower maintenance expenses over time, resulting in improved long-term economic value. Evaluating lifecycle costs, including repair frequency and material longevity, favors asphalt concrete in infrastructure projects where budget efficiency and performance are critical.

Asphalt Concrete vs Tar-bound Macadam Infographic

materialdif.com

materialdif.com