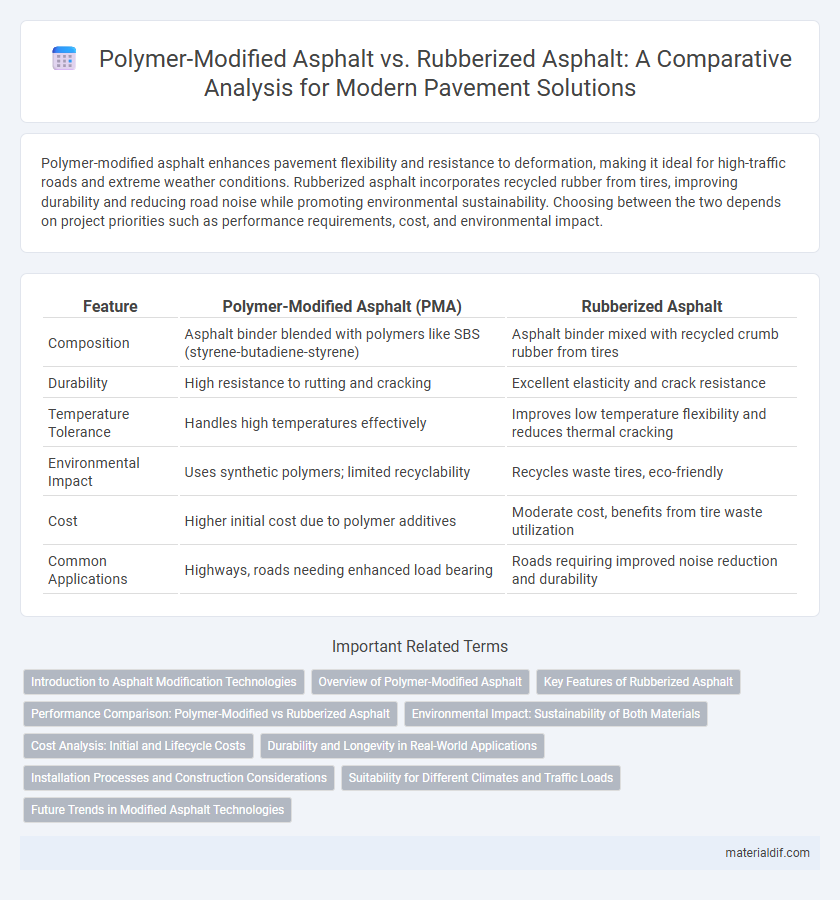

Polymer-modified asphalt enhances pavement flexibility and resistance to deformation, making it ideal for high-traffic roads and extreme weather conditions. Rubberized asphalt incorporates recycled rubber from tires, improving durability and reducing road noise while promoting environmental sustainability. Choosing between the two depends on project priorities such as performance requirements, cost, and environmental impact.

Table of Comparison

| Feature | Polymer-Modified Asphalt (PMA) | Rubberized Asphalt |

|---|---|---|

| Composition | Asphalt binder blended with polymers like SBS (styrene-butadiene-styrene) | Asphalt binder mixed with recycled crumb rubber from tires |

| Durability | High resistance to rutting and cracking | Excellent elasticity and crack resistance |

| Temperature Tolerance | Handles high temperatures effectively | Improves low temperature flexibility and reduces thermal cracking |

| Environmental Impact | Uses synthetic polymers; limited recyclability | Recycles waste tires, eco-friendly |

| Cost | Higher initial cost due to polymer additives | Moderate cost, benefits from tire waste utilization |

| Common Applications | Highways, roads needing enhanced load bearing | Roads requiring improved noise reduction and durability |

Introduction to Asphalt Modification Technologies

Polymer-modified asphalt incorporates synthetic polymers such as styrene-butadiene-styrene (SBS) to enhance elasticity, temperature susceptibility, and resistance to deformation. Rubberized asphalt utilizes recycled crumb rubber from tires, improving flexibility, crack resistance, and noise reduction. These asphalt modification technologies optimize pavement durability and performance under varying climatic and traffic conditions.

Overview of Polymer-Modified Asphalt

Polymer-modified asphalt (PMA) enhances traditional asphalt binders by incorporating polymers such as styrene-butadiene-styrene (SBS) or ethylene-vinyl acetate (EVA), resulting in improved elasticity, durability, and resistance to deformation. This modification increases the asphalt's ability to withstand temperature fluctuations, reduces cracking, and extends pavement lifespan compared to conventional asphalt. PMA is widely used in high-traffic roadways and airports due to its superior performance under heavy loads and extreme weather conditions.

Key Features of Rubberized Asphalt

Rubberized asphalt incorporates recycled tire rubber to enhance flexibility, crack resistance, and noise reduction, making it eco-friendly and durable. Its high elasticity improves pavement performance under temperature fluctuations and heavy traffic loads. This material also offers superior resistance to wear and aging compared to polymer-modified asphalt, extending pavement lifespan.

Performance Comparison: Polymer-Modified vs Rubberized Asphalt

Polymer-modified asphalt (PMA) offers enhanced flexibility, improved resistance to rutting, and greater durability under high temperatures compared to traditional asphalt mixes. In contrast, rubberized asphalt incorporates crumb rubber from recycled tires, providing superior crack resistance, noise reduction, and elasticity, especially beneficial in colder climates. Performance studies indicate that while PMA excels in heavy traffic load durability, rubberized asphalt delivers better environmental sustainability and longevity in freeze-thaw cycles.

Environmental Impact: Sustainability of Both Materials

Polymer-modified asphalt enhances pavement durability and reduces maintenance frequency, leading to lower material consumption and carbon emissions over time. Rubberized asphalt repurposes waste tires, significantly diverting rubber from landfills and promoting circular economy benefits. Both materials contribute to sustainability by improving road lifespan, but rubberized asphalt offers additional environmental advantages through effective waste tire recycling.

Cost Analysis: Initial and Lifecycle Costs

Polymer-modified asphalt generally incurs higher initial costs due to the expense of polymer additives, whereas rubberized asphalt, derived from recycled tires, often presents lower upfront expenses but fluctuates with rubber material prices. Lifecycle cost analysis reveals polymer-modified asphalt tends to offer enhanced durability and reduced maintenance needs, potentially lowering long-term expenditures compared to rubberized asphalt, which may require more frequent repairs. Evaluating total cost of ownership must consider local raw material costs, performance benefits, and maintenance cycles to determine the most economical choice for paving projects.

Durability and Longevity in Real-World Applications

Polymer-modified asphalt exhibits enhanced durability through improved resistance to rutting, cracking, and deformation under heavy traffic loads, extending pavement lifespan significantly compared to conventional mixes. Rubberized asphalt offers superior flexibility and crack resistance, particularly in regions with extreme temperature variations, contributing to longer service life by absorbing stress and reducing thermal contraction damage. Real-world applications demonstrate polymer-modified asphalt often performs better on high-traffic highways, while rubberized asphalt provides advantages in urban streets and areas with frequent freeze-thaw cycles.

Installation Processes and Construction Considerations

Polymer-modified asphalt requires precise temperature control during mixing and installation to ensure optimal adhesion and flexibility, often demanding specialized equipment and trained personnel. Rubberized asphalt involves incorporating crumb rubber from recycled tires, necessitating extended blending times and careful handling to maintain uniform distribution and prevent segregation. Construction considerations for both include traffic load expectations and environmental factors, with polymer-modified asphalt typically offering enhanced resistance to deformation, while rubberized asphalt improves noise reduction and extends pavement life.

Suitability for Different Climates and Traffic Loads

Polymer-modified asphalt demonstrates superior flexibility and resistance to rutting, making it highly effective for regions with extreme temperature variations and heavy traffic volumes. Rubberized asphalt offers enhanced crack resistance and noise reduction, particularly suited for moderate climates and highways with medium to light vehicle loads. Choosing between these materials depends on specific climate challenges and traffic intensity to optimize pavement durability and performance.

Future Trends in Modified Asphalt Technologies

Polymer-modified asphalt (PMA) and rubberized asphalt are driving innovations in pavement durability and sustainability, with future trends emphasizing enhanced elasticity and resistance to temperature variations. Emerging technologies in nanomaterials and bio-based polymers are poised to improve adhesion and aging performance, reducing maintenance costs and environmental impact. The integration of recycling methods with advanced modifiers aims to create more resilient infrastructure aligned with green construction practices.

Polymer-Modified Asphalt vs Rubberized Asphalt Infographic

materialdif.com

materialdif.com