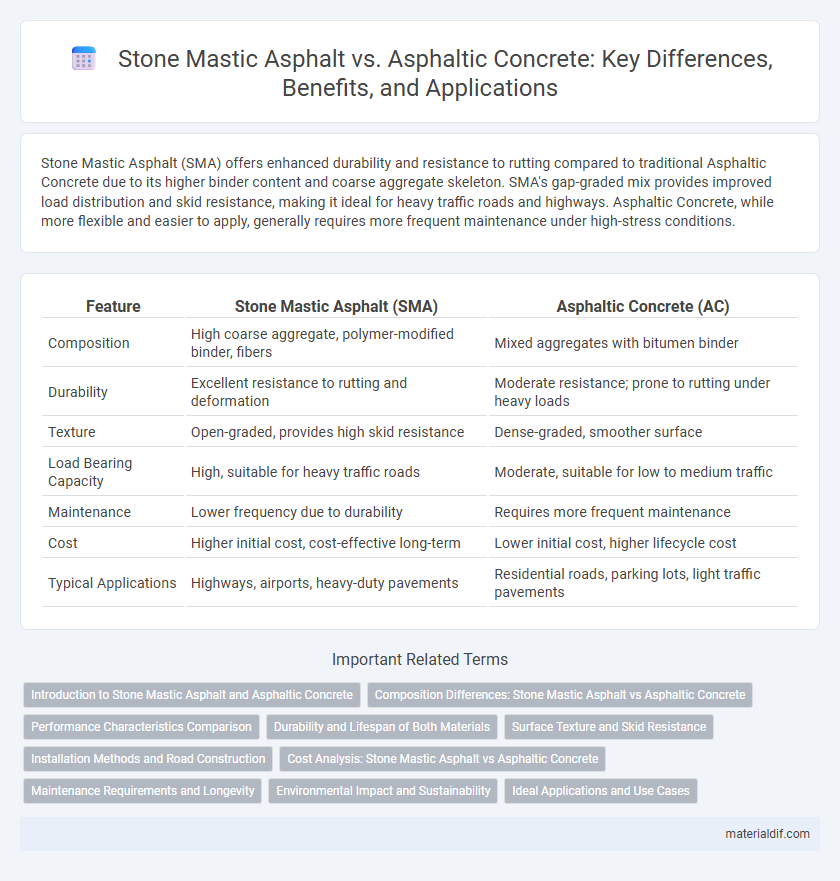

Stone Mastic Asphalt (SMA) offers enhanced durability and resistance to rutting compared to traditional Asphaltic Concrete due to its higher binder content and coarse aggregate skeleton. SMA's gap-graded mix provides improved load distribution and skid resistance, making it ideal for heavy traffic roads and highways. Asphaltic Concrete, while more flexible and easier to apply, generally requires more frequent maintenance under high-stress conditions.

Table of Comparison

| Feature | Stone Mastic Asphalt (SMA) | Asphaltic Concrete (AC) |

|---|---|---|

| Composition | High coarse aggregate, polymer-modified binder, fibers | Mixed aggregates with bitumen binder |

| Durability | Excellent resistance to rutting and deformation | Moderate resistance; prone to rutting under heavy loads |

| Texture | Open-graded, provides high skid resistance | Dense-graded, smoother surface |

| Load Bearing Capacity | High, suitable for heavy traffic roads | Moderate, suitable for low to medium traffic |

| Maintenance | Lower frequency due to durability | Requires more frequent maintenance |

| Cost | Higher initial cost, cost-effective long-term | Lower initial cost, higher lifecycle cost |

| Typical Applications | Highways, airports, heavy-duty pavements | Residential roads, parking lots, light traffic pavements |

Introduction to Stone Mastic Asphalt and Asphaltic Concrete

Stone Mastic Asphalt (SMA) is a durable pavement material designed with a gap-graded aggregate structure and a high binder content, offering excellent rut resistance and longevity. Asphaltic Concrete (AC) consists of a well-graded aggregate mix bound with bitumen, providing smooth surface textures and versatile applications in road construction. Both materials serve critical roles in infrastructure, with SMA preferred for heavy traffic areas due to its strength, while AC is widely used for general paving needs.

Composition Differences: Stone Mastic Asphalt vs Asphaltic Concrete

Stone Mastic Asphalt (SMA) features a coarse aggregate skeleton with high air voids, stabilized by a rich mastic of filler and bitumen, providing enhanced durability and rut resistance. Asphaltic Concrete (AC) consists of a more uniform mixture of fine and coarse aggregates with less binder, offering smoother texture but lower resistance to deformation. The key compositional difference lies in SMA's higher binder content and gap-graded aggregate structure compared to AC's dense-graded arrangement.

Performance Characteristics Comparison

Stone Mastic Asphalt (SMA) offers superior rut resistance and durability compared to traditional Asphaltic Concrete, making it ideal for high-traffic and heavy-load roads. SMA's gap-graded aggregate structure combined with a rich bitumen binder enhances deformation resistance and skid resistance under varying climatic conditions. Asphaltic Concrete typically exhibits faster aging and fatigue cracking, while SMA maintains structural integrity and surface texture over an extended lifespan.

Durability and Lifespan of Both Materials

Stone Mastic Asphalt (SMA) exhibits superior durability compared to Asphaltic Concrete due to its high binder content and coarse aggregate skeleton, which enhances resistance to rutting and deformation under heavy traffic loads. The lifespan of SMA typically ranges from 15 to 20 years, often outperforming Asphaltic Concrete, which generally lasts between 10 to 15 years depending on traffic intensity and environmental conditions. Enhanced durability of SMA reduces maintenance frequency and long-term rehabilitation costs, making it a preferred choice for high-stress pavement applications.

Surface Texture and Skid Resistance

Stone Mastic Asphalt (SMA) features a coarse surface texture with a high stone content, providing enhanced skid resistance and durability compared to traditional Asphaltic Concrete. The rut-resistant structure of SMA improves traction in wet conditions, reducing the risk of accidents on pavement surfaces. Asphaltic Concrete typically exhibits a smoother texture, which may offer lower skid resistance but provides a quieter, more comfortable ride.

Installation Methods and Road Construction

Stone Mastic Asphalt (SMA) features a distinct installation method involving a gap-graded aggregate mix that is compacted using heavy rollers to create a durable and rut-resistant surface ideal for high-traffic roads. Asphaltic Concrete (AC) installation typically uses a dense-graded aggregate mix, compacted with vibratory rollers to achieve smoothness and structural integrity, making it suitable for a wide range of pavement applications. In road construction, SMA's enhanced binder content and fiber reinforcement reduce deformation, while AC provides a cost-effective solution with quicker laying processes for general-use pavements.

Cost Analysis: Stone Mastic Asphalt vs Asphaltic Concrete

Stone Mastic Asphalt (SMA) typically incurs higher initial material costs due to its dense-graded mix design and use of polymer-modified binders, but it offers longer service life and enhanced rut resistance compared to conventional Asphaltic Concrete (AC). Asphaltic Concrete often has lower upfront costs, making it suitable for projects with budget constraints, yet frequent maintenance and earlier rehabilitation increase its long-term expenses. Cost analysis shows that while SMA demands greater initial investment, its durability and reduced maintenance cycles provide better life-cycle cost efficiency over traditional AC pavements.

Maintenance Requirements and Longevity

Stone Mastic Asphalt (SMA) demonstrates superior durability compared to traditional Asphaltic Concrete due to its void-rich structure and high binder content, resulting in enhanced resistance to rutting and deformation. Maintenance requirements for SMA are generally lower, as its dense skeleton and strong aggregate interlock reduce crack formation and surface wear over time. In contrast, Asphaltic Concrete requires more frequent repairs and resurfacing to address issues such as cracking and potholes, impacting its overall longevity and lifecycle costs.

Environmental Impact and Sustainability

Stone Mastic Asphalt (SMA) offers enhanced durability and longer service life compared to traditional Asphaltic Concrete, which reduces the frequency of repairs and associated resource consumption. SMA's higher binder content and use of gap-graded aggregates improve resistance to rutting and deformation, lowering the carbon footprint over the pavement lifecycle. Asphaltic Concrete, while typically less costly upfront, may require more frequent maintenance, resulting in increased energy use and greenhouse gas emissions throughout its operational life.

Ideal Applications and Use Cases

Stone Mastic Asphalt (SMA) is ideal for high-traffic roads and heavy-duty pavements due to its strong stone-on-stone structure, providing exceptional rut resistance and durability under heavy loads. Asphaltic Concrete is better suited for lighter traffic areas, such as residential streets and low-volume roads, where flexibility and ease of repair are priorities. SMA's enhanced resistance to deformation and aging makes it preferred for highways, airport runways, and urban arterials requiring long-term performance.

Stone Mastic Asphalt vs Asphaltic Concrete Infographic

materialdif.com

materialdif.com