Hot Mix Asphalt is produced at higher temperatures, typically between 300degF and 350degF, resulting in a denser, more durable pavement ideal for heavy traffic and long-lasting roads. Warm Mix Asphalt is made at lower temperatures, around 200degF to 250degF, reducing fuel consumption and emissions while maintaining sufficient strength for many applications. Choosing between Hot Mix and Warm Mix Asphalt depends on project requirements, environmental considerations, and cost efficiency.

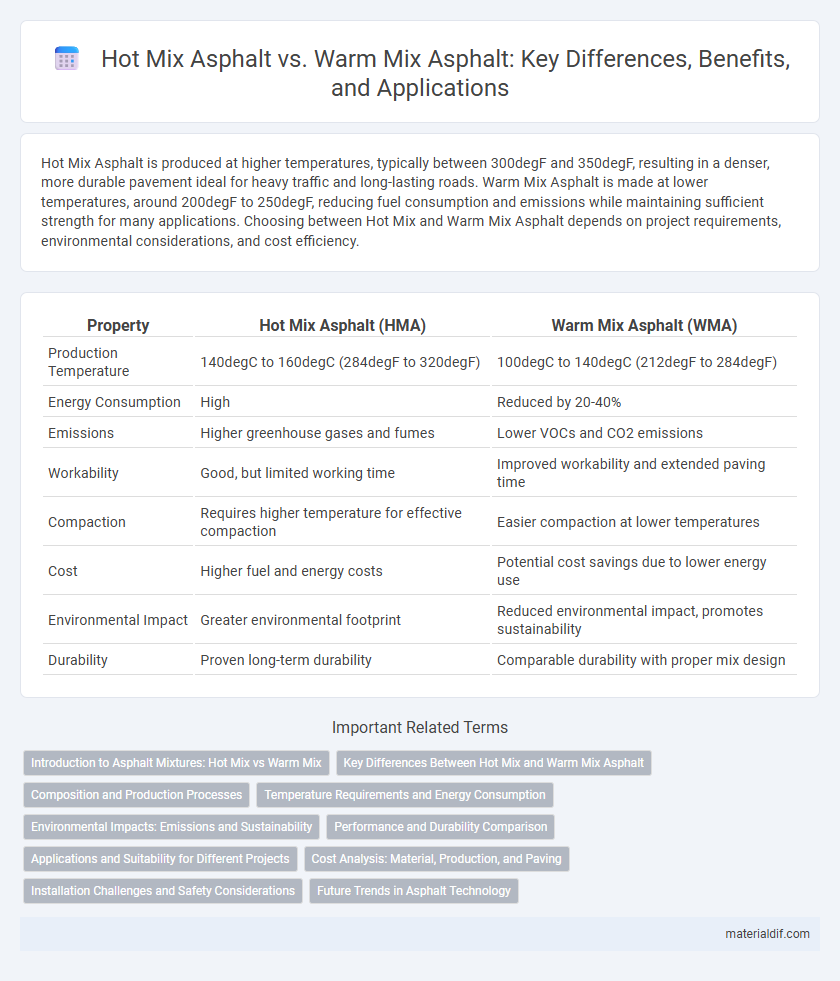

Table of Comparison

| Property | Hot Mix Asphalt (HMA) | Warm Mix Asphalt (WMA) |

|---|---|---|

| Production Temperature | 140degC to 160degC (284degF to 320degF) | 100degC to 140degC (212degF to 284degF) |

| Energy Consumption | High | Reduced by 20-40% |

| Emissions | Higher greenhouse gases and fumes | Lower VOCs and CO2 emissions |

| Workability | Good, but limited working time | Improved workability and extended paving time |

| Compaction | Requires higher temperature for effective compaction | Easier compaction at lower temperatures |

| Cost | Higher fuel and energy costs | Potential cost savings due to lower energy use |

| Environmental Impact | Greater environmental footprint | Reduced environmental impact, promotes sustainability |

| Durability | Proven long-term durability | Comparable durability with proper mix design |

Introduction to Asphalt Mixtures: Hot Mix vs Warm Mix

Hot Mix Asphalt (HMA) is produced at temperatures between 300degF and 350degF, providing high durability ideal for heavy traffic roads and highways. Warm Mix Asphalt (WMA) is manufactured at lower temperatures, typically 200degF to 250degF, reducing energy consumption and emissions while maintaining comparable performance. Both mixtures use aggregates and bitumen binders but differ in production temperature, environmental impact, and suitability for specific paving conditions.

Key Differences Between Hot Mix and Warm Mix Asphalt

Hot Mix Asphalt (HMA) is produced at higher temperatures, typically between 300degF and 350degF, resulting in superior durability and strength for high-traffic pavements. Warm Mix Asphalt (WMA) is manufactured at lower temperatures, around 212degF to 275degF, reducing energy consumption and emissions while allowing longer hauling distances. Key differences include energy usage, environmental impact, workability at lower temperatures, and overall lifecycle costs.

Composition and Production Processes

Hot Mix Asphalt (HMA) consists of aggregates combined with asphalt cement heated to temperatures between 300degF and 350degF, ensuring optimal binder coating and workability during paving; its production involves high-energy drying and mixing processes at elevated temperatures. Warm Mix Asphalt (WMA) incorporates organic additives, chemical agents, or water-based foaming techniques to lower mixing and compaction temperatures to approximately 200degF-250degF, reducing energy consumption and emissions while maintaining aggregate-asphalt adhesion. Both types use similar base materials, but WMA's innovative production processes improve environmental performance without compromising pavement durability.

Temperature Requirements and Energy Consumption

Hot Mix Asphalt (HMA) is produced at temperatures ranging from 300degF to 350degF, requiring significant energy consumption for heating aggregates and bitumen. Warm Mix Asphalt (WMA) is manufactured at lower temperatures, typically between 212degF and 275degF, which reduces fuel use by up to 30%, resulting in lower greenhouse gas emissions and enhanced energy efficiency. The reduced temperature requirements of WMA contribute to cost savings and improved workplace safety while maintaining comparable performance to HMA.

Environmental Impacts: Emissions and Sustainability

Hot Mix Asphalt (HMA) production releases higher levels of greenhouse gases and volatile organic compounds compared to Warm Mix Asphalt (WMA), which uses lower temperatures to reduce fuel consumption and emissions by up to 30%. WMA enhances sustainability by allowing the incorporation of recycled materials without compromising pavement quality, thereby lowering the carbon footprint associated with raw material extraction. The reduced energy demands and emissions of WMA contribute significantly to meeting environmental regulations and promoting eco-friendly infrastructure development.

Performance and Durability Comparison

Hot Mix Asphalt (HMA) offers superior durability and load-bearing capacity due to its high production temperatures, resulting in better compaction and reduced moisture susceptibility. Warm Mix Asphalt (WMA) provides comparable performance with lower emissions and energy use but may have slightly reduced long-term resistance to rutting and cracking in heavy traffic conditions. Both mixtures perform well under typical traffic loads, but HMA generally excels in extreme temperature and heavy-load environments.

Applications and Suitability for Different Projects

Hot Mix Asphalt (HMA) is preferred for high-traffic highways and heavy-duty pavements due to its durability and high temperature application, making it ideal for long-lasting road surfaces. Warm Mix Asphalt (WMA) is suitable for urban projects, overlays, and rehabilitation where lower production temperatures reduce emissions and energy consumption while improving compaction in cooler weather. WMA's reduced environmental footprint and ease of application make it well-suited for sustainable infrastructure projects and areas with stricter environmental regulations.

Cost Analysis: Material, Production, and Paving

Hot Mix Asphalt (HMA) typically incurs higher production costs due to elevated heating temperatures requiring more energy, resulting in increased fuel consumption and utility expenses. Warm Mix Asphalt (WMA) lowers material and production costs by incorporating additives that reduce mixing and compaction temperatures, leading to energy savings and reduced greenhouse gas emissions. In paving operations, WMA enables extended hauling distances and longer workability, potentially reducing labor and equipment costs compared to HMA.

Installation Challenges and Safety Considerations

Hot Mix Asphalt requires higher temperatures around 300degF to 350degF during installation, posing increased risks of burns and heat-related injuries for workers, while Warm Mix Asphalt is produced and laid at temperatures 30degF to 120degF lower, enhancing on-site safety by reducing heat exposure. The higher temperatures in Hot Mix Asphalt installation demand greater precautions, specialized protective equipment, and ventilation measures to mitigate fumes and gases, whereas Warm Mix Asphalt's cooler application reduces these hazards and allows for extended paving seasons in cooler climates. Installation challenges for Hot Mix Asphalt include dealing with rapid cooling that affects compaction time, while Warm Mix Asphalt offers improved workability and compaction flexibility, although its performance under heavy loads requires careful material formulation.

Future Trends in Asphalt Technology

Hot Mix Asphalt (HMA) has long been the industry standard due to its durability and performance at high temperatures, but Warm Mix Asphalt (WMA) is rapidly gaining traction for its environmental benefits and energy efficiency, reducing greenhouse gas emissions by up to 30%. Emerging asphalt technologies are incorporating bio-based additives and recycled materials to enhance the sustainability and longevity of both HMA and WMA. Future trends indicate a shift towards smart asphalt with embedded sensors for real-time monitoring, improving maintenance strategies and infrastructure resilience.

Hot Mix Asphalt vs Warm Mix Asphalt Infographic

materialdif.com

materialdif.com