Asphalt overlay involves applying a new layer of asphalt directly over the existing pavement to improve surface smoothness and extend pavement life, while asphalt milling removes the top layer of damaged or deteriorated asphalt prior to resurfacing, allowing for better bonding and improved surface profile. Asphalt milling is often preferred when the underlying base is unstable or when significant pavement distress exists, as it addresses structural issues before overlaying. Choosing between asphalt overlay and milling depends on pavement condition, budget, and long-term performance goals.

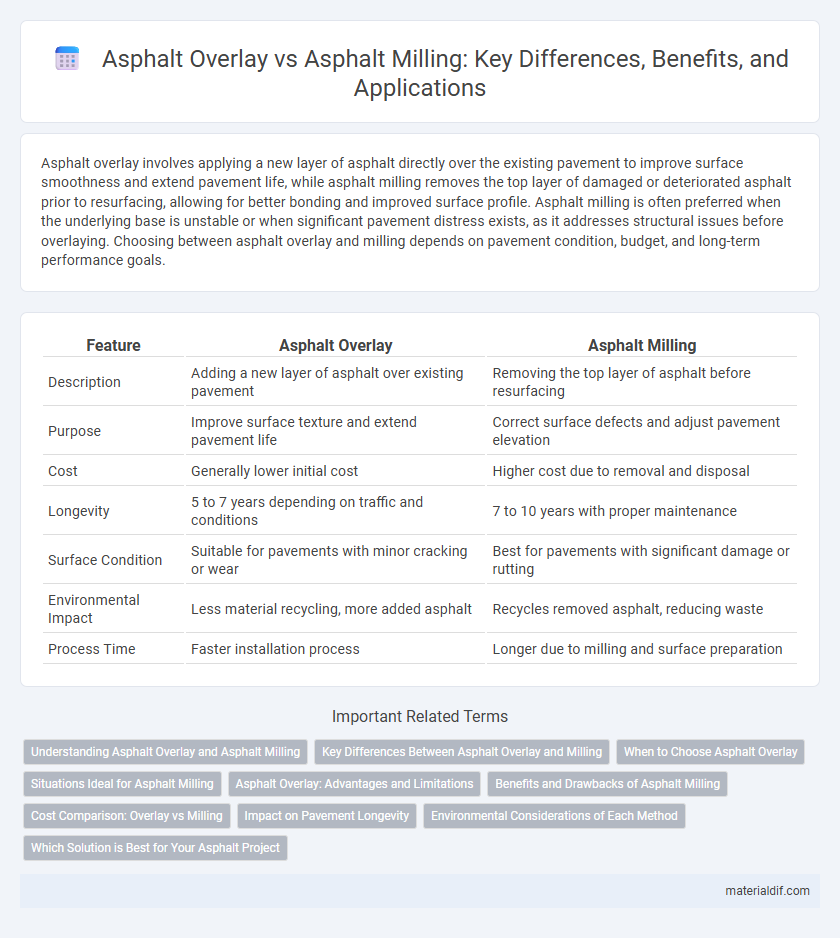

Table of Comparison

| Feature | Asphalt Overlay | Asphalt Milling |

|---|---|---|

| Description | Adding a new layer of asphalt over existing pavement | Removing the top layer of asphalt before resurfacing |

| Purpose | Improve surface texture and extend pavement life | Correct surface defects and adjust pavement elevation |

| Cost | Generally lower initial cost | Higher cost due to removal and disposal |

| Longevity | 5 to 7 years depending on traffic and conditions | 7 to 10 years with proper maintenance |

| Surface Condition | Suitable for pavements with minor cracking or wear | Best for pavements with significant damage or rutting |

| Environmental Impact | Less material recycling, more added asphalt | Recycles removed asphalt, reducing waste |

| Process Time | Faster installation process | Longer due to milling and surface preparation |

Understanding Asphalt Overlay and Asphalt Milling

Asphalt overlay involves applying a new layer of asphalt over the existing surface to restore smoothness and improve durability, typically used when the underlying base is still in good condition. Asphalt milling removes the top layer of damaged or deteriorated asphalt to prepare the surface for a fresh overlay, ensuring proper bonding and addressing structural issues. Understanding the difference helps in selecting the right pavement rehabilitation technique to extend the lifespan of roads efficiently.

Key Differences Between Asphalt Overlay and Milling

Asphalt overlay involves applying a new layer of asphalt over an existing surface to enhance smoothness and extend pavement life, while asphalt milling removes the top layers of damaged pavement to prepare for resurfacing. Overlay is typically faster and less expensive but may not address deep structural issues, whereas milling provides a solid foundation by eliminating deterioration and ensuring better adhesion for the new asphalt. Choosing between the two depends on pavement condition, budget, and long-term maintenance goals.

When to Choose Asphalt Overlay

Asphalt overlay is ideal when the existing pavement is structurally sound but exhibits surface wear and minor cracks, providing a cost-effective and quick solution that extends the pavement's lifespan. It enhances the smoothness and load-bearing capacity by adding a new layer without removing the underlying material, making it a preferred choice for roads with aging surface distress but intact base layers. Choosing overlay avoids the higher expense of full-depth replacement while improving skid resistance and sealing cracks against water intrusion.

Situations Ideal for Asphalt Milling

Asphalt milling is ideal for situations where the pavement has localized damage, such as extensive cracks, potholes, or uneven surfaces that require removal of the top layer before resurfacing. This process preserves the base layer integrity, reduces waste by recycling the removed asphalt, and ensures a stronger bond for the new overlay. Airports, highways, and heavily trafficked roads often benefit from asphalt milling to maintain long-term pavement performance.

Asphalt Overlay: Advantages and Limitations

Asphalt overlay provides a cost-effective solution for improving pavement surface by adding a new layer of asphalt, enhancing durability and extending pavement life without extensive removal of the existing layer. This method is ideal for addressing minor surface deterioration such as cracks or rutting but may not be suitable for pavements with severe structural damage or significant underlying issues. While overlays improve aesthetics and skid resistance, their limitations include potential reflective cracking and the inability to correct underlying base failures, which may necessitate milling in more compromised scenarios.

Benefits and Drawbacks of Asphalt Milling

Asphalt milling effectively removes the top layer of damaged pavement, providing a stable base for new asphalt overlay and enhancing surface texture for improved skid resistance. This process reduces waste by recycling old asphalt, lowering project costs and environmental impact, but may require additional surface leveling to address underlying pavement issues. Milling improves drainage and extends pavement life, yet it can result in uneven surfaces if not properly executed, potentially increasing maintenance needs over time.

Cost Comparison: Overlay vs Milling

Asphalt overlay typically costs between $2 to $4 per square foot, offering a more affordable resurfacing option compared to asphalt milling, which ranges from $3 to $6 per square foot due to the added labor and equipment required for removing the existing pavement layer. Milling involves grinding away the top layer to address significant damage, often leading to higher upfront expenses but potentially extending pavement life and reducing future repair costs. Choosing between overlay and milling depends on the pavement's condition and long-term budget considerations, with milling favored for extensive repairs despite its higher initial cost.

Impact on Pavement Longevity

Asphalt overlay involves adding a new layer of asphalt over the existing pavement, enhancing surface durability and extending pavement longevity by protecting against weather and traffic wear. Asphalt milling removes the top layers of damaged pavement, enabling better bonding of new asphalt and addressing structural issues, which can significantly improve the lifespan of the pavement by preventing water infiltration and base damage. Proper selection between overlay and milling depends on the pavement's condition, with milling often preferred for more severe distress to maximize long-term durability.

Environmental Considerations of Each Method

Asphalt overlay minimally disturbs the existing pavement, reducing construction waste and preserving natural resources by reusing the base layer, leading to lower environmental impact through decreased emissions and landfill use. Asphalt milling involves removing the top layer of damaged pavement, which generates reclaimed asphalt pavement (RAP) that can be recycled into new asphalt, reducing the need for virgin materials and conserving energy. Both methods contribute to sustainable pavement management, but milling offers greater potential for material recycling and resource conservation.

Which Solution is Best for Your Asphalt Project

Asphalt overlay involves applying a new layer of asphalt over the existing surface, providing a cost-effective solution for minor cracks and surface wear, while asphalt milling removes the top layer of damaged pavement to ensure a smoother and more durable base before repaving. Choosing the best solution depends on the severity of pavement deterioration, with milling ideal for significant structural damage and overlay suitable for maintaining surfaces with minimal distress. Evaluating pavement condition through professional assessment ensures the selection of the most effective method for longevity and cost efficiency in asphalt projects.

Asphalt Overlay vs Asphalt Milling Infographic

materialdif.com

materialdif.com