Bitumen and tar are both dark, viscous substances used in road construction but differ significantly in composition and properties. Bitumen, a petroleum derivative, offers superior durability, water resistance, and flexibility, making it ideal for asphalt pavements. Tar, derived from coal or wood, is more brittle and prone to cracking, which limits its use in modern road surfacing applications.

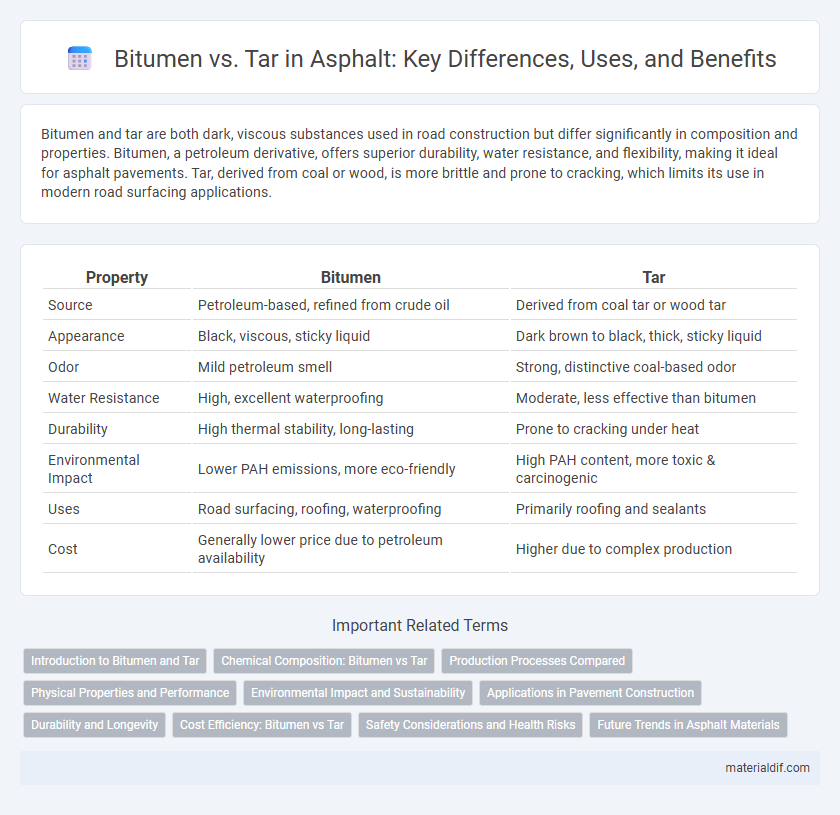

Table of Comparison

| Property | Bitumen | Tar |

|---|---|---|

| Source | Petroleum-based, refined from crude oil | Derived from coal tar or wood tar |

| Appearance | Black, viscous, sticky liquid | Dark brown to black, thick, sticky liquid |

| Odor | Mild petroleum smell | Strong, distinctive coal-based odor |

| Water Resistance | High, excellent waterproofing | Moderate, less effective than bitumen |

| Durability | High thermal stability, long-lasting | Prone to cracking under heat |

| Environmental Impact | Lower PAH emissions, more eco-friendly | High PAH content, more toxic & carcinogenic |

| Uses | Road surfacing, roofing, waterproofing | Primarily roofing and sealants |

| Cost | Generally lower price due to petroleum availability | Higher due to complex production |

Introduction to Bitumen and Tar

Bitumen and tar are two key binding agents used in road construction, with bitumen derived from crude oil and tar obtained from coal or wood. Bitumen is a viscous, black material known for its excellent waterproofing and adhesive properties, making it the preferred choice in modern asphalt production. Tar, while historically used, is less common today due to its higher toxicity and environmental concerns compared to the more stable and less hazardous bitumen.

Chemical Composition: Bitumen vs Tar

Bitumen is primarily composed of complex hydrocarbons derived from crude oil distillation, rich in asphaltenes and maltenes, whereas tar consists mainly of polycyclic aromatic hydrocarbons obtained through the destructive distillation of coal or wood. The chemical structure of bitumen provides greater flexibility and resistance to oxidation, while tar contains higher levels of phenols and heterocyclic compounds, making it more brittle and prone to cracking. These compositional differences critically influence their performance and environmental impact in asphalt applications.

Production Processes Compared

Bitumen is produced through the fractional distillation of crude oil, where it remains as the heavy residue after lighter hydrocarbons are separated, resulting in a viscous and adhesive material used in asphalt production. Tar is derived from the destructive distillation of organic materials such as coal, wood, or peat, creating a mixture rich in aromatic hydrocarbons with distinct chemical properties. The production process differences lead to bitumen's superior durability and weather resistance, whereas tar is more brittle and less stable under prolonged exposure to heat and ultraviolet light.

Physical Properties and Performance

Bitumen features higher viscosity and better adhesive properties than tar, making it more durable for asphalt pavement applications. Tar exhibits greater brittleness and lower resistance to water and oxidation, leading to potential cracking under thermal stress. The superior waterproofing and aging resistance of bitumen enhance the longevity and performance of road surfaces compared to tar-based binders.

Environmental Impact and Sustainability

Bitumen, derived from crude oil, has a lower environmental impact compared to tar, which is produced from coal and contains carcinogenic compounds such as polycyclic aromatic hydrocarbons (PAHs). Bitumen's production and use in asphalt are associated with fewer toxic emissions and better energy efficiency, contributing to improved sustainability in road construction. Sustainable alternatives like bio-based bitumen and recycled asphalt materials further reduce ecological footprints and support circular economy principles.

Applications in Pavement Construction

Bitumen is predominantly used in pavement construction due to its superior adhesive properties, water resistance, and flexibility, making it ideal for asphalt concrete in roads and highways. Tar, derived from coal or wood, is less common in modern pavement projects because of its brittleness and environmental concerns but remains in some industrial or specialized applications. The choice between bitumen and tar impacts pavement durability, maintenance requirements, and environmental compliance in infrastructure development.

Durability and Longevity

Bitumen offers superior durability and longevity compared to tar, making it the preferred binder in modern asphalt pavements. Bitumen's resistance to weathering, UV radiation, and oxidation significantly extends the lifespan of roofing and road surfaces. Tar, derived from coal, tends to be more brittle and less stable under heat and environmental stress, leading to faster degradation.

Cost Efficiency: Bitumen vs Tar

Bitumen generally offers greater cost efficiency than tar due to its lower production and maintenance expenses, making it a preferred choice for large-scale paving projects. Tar requires more frequent repairs and has higher environmental compliance costs, which increases the overall expenditure over time. The longevity and durability of bitumen surfaces contribute to reduced lifecycle costs, enhancing its economic advantage in road construction.

Safety Considerations and Health Risks

Bitumen, derived from petroleum, is widely used in asphalt production and poses fewer health risks compared to tar, which is a coal derivative containing higher levels of carcinogenic polycyclic aromatic hydrocarbons (PAHs). Exposure to tar fumes during application can cause respiratory issues, skin irritation, and has been linked to an increased risk of cancer, while bitumen fumes, though still hazardous, tend to have lower toxicity levels. Proper ventilation, protective equipment, and adherence to safety protocols are essential when handling both substances to minimize health risks for workers in the asphalt industry.

Future Trends in Asphalt Materials

Bitumen, derived from crude oil, is increasingly favored over tar due to its superior durability and lower environmental impact in asphalt production. Future trends emphasize the development of bio-based bitumen alternatives and the integration of recycled materials to enhance sustainability and performance. Innovations in polymer-modified bitumen are also advancing asphalt materials by improving resistance to temperature fluctuations and traffic loads.

Bitumen vs Tar Infographic

materialdif.com

materialdif.com