Slurry seal and micro surfacing are both effective pavement preservation techniques designed to extend the life of asphalt surfaces. Slurry seal uses a mixture of emulsified asphalt, water, and fine aggregate to create a thin protective layer ideal for low to moderate traffic areas, while micro surfacing incorporates polymer-modified emulsions and coarser aggregates, offering faster curing times and greater durability on high-traffic roads. Choosing between slurry seal and micro surfacing depends on factors such as traffic load, desired lifespan, and project timeline.

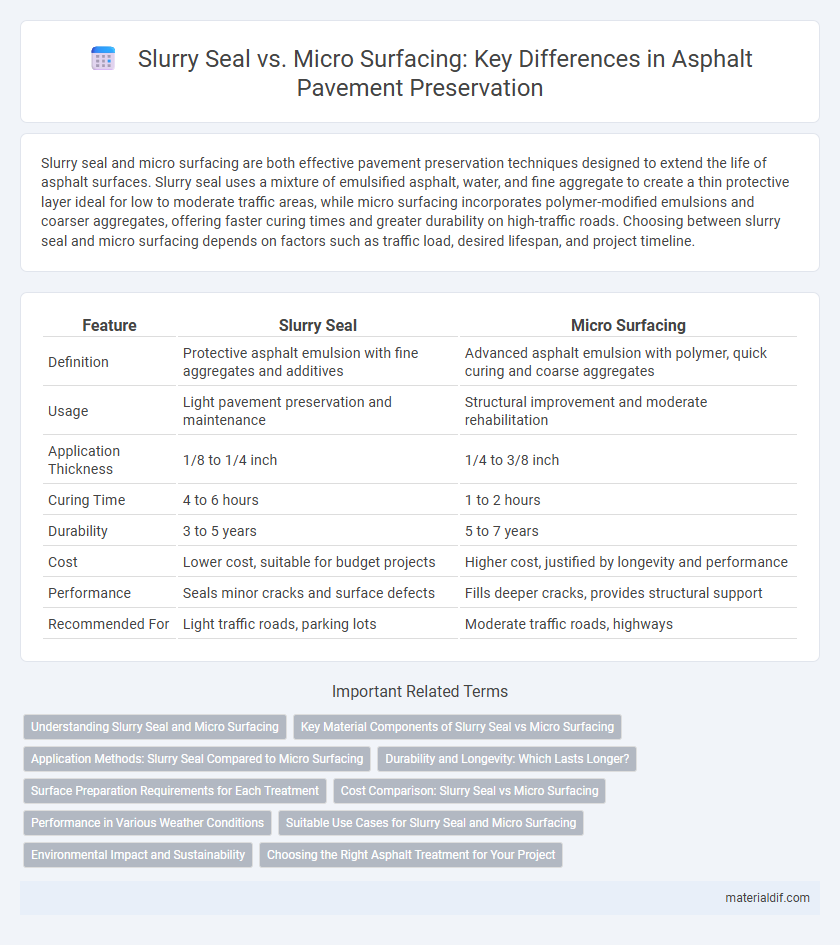

Table of Comparison

| Feature | Slurry Seal | Micro Surfacing |

|---|---|---|

| Definition | Protective asphalt emulsion with fine aggregates and additives | Advanced asphalt emulsion with polymer, quick curing and coarse aggregates |

| Usage | Light pavement preservation and maintenance | Structural improvement and moderate rehabilitation |

| Application Thickness | 1/8 to 1/4 inch | 1/4 to 3/8 inch |

| Curing Time | 4 to 6 hours | 1 to 2 hours |

| Durability | 3 to 5 years | 5 to 7 years |

| Cost | Lower cost, suitable for budget projects | Higher cost, justified by longevity and performance |

| Performance | Seals minor cracks and surface defects | Fills deeper cracks, provides structural support |

| Recommended For | Light traffic roads, parking lots | Moderate traffic roads, highways |

Understanding Slurry Seal and Micro Surfacing

Slurry seal is a mixture of asphalt emulsion, fine aggregate, water, and additives applied as a thin protective coating to rejuvenate aged asphalt surfaces and seal minor cracks. Micro surfacing includes polymer-modified asphalt emulsions and is designed for thicker applications, providing quicker curing times and enhanced durability on roads with moderate distress. Both treatments improve pavement texture and skid resistance, but micro surfacing offers superior performance on higher traffic roads due to its enhanced bonding and structural benefits.

Key Material Components of Slurry Seal vs Micro Surfacing

Slurry seal primarily consists of a blend of asphalt emulsion, fine aggregate, mineral filler, water, and additives designed to create a thin, flexible surface layer. Micro surfacing incorporates polymer-modified asphalt emulsions, coarser aggregates, mineral fillers, water, and chemical additives to achieve faster curing times and enhanced durability. The polymer modifiers in micro surfacing significantly improve resistance to cracking and rutting compared to the traditional emulsion used in slurry seal.

Application Methods: Slurry Seal Compared to Micro Surfacing

Slurry seal application involves a mixture of asphalt emulsion, fine aggregate, and water applied with simpler equipment, allowing for faster curing times and suitability for light to moderate traffic surfaces. Micro surfacing uses a polymer-modified asphalt emulsion combined with specific aggregates and additives, requiring specialized automated machines for precise spreading and quicker traffic reopening. Both methods enhance pavement longevity, but micro surfacing provides a thicker, more durable layer ideal for heavier traffic, while slurry seal is optimal for preventive maintenance on lower volume roads.

Durability and Longevity: Which Lasts Longer?

Slurry seal typically offers a lifespan of 3 to 7 years, making it suitable for maintenance on roads with lighter traffic. Micro surfacing provides enhanced durability, often lasting 5 to 8 years or more, due to its quick-curing polymer-modified asphalt emulsion that resists rutting and cracking. For high-traffic areas requiring extended longevity, micro surfacing is generally the preferable choice over slurry seal.

Surface Preparation Requirements for Each Treatment

Slurry seal requires a clean, dry surface free of debris and loose materials to ensure proper bonding and uniform application, often involving sweeping and minor crack repairs. Micro surfacing demands more thorough surface preparation, including cleaning, patching, and sometimes milling to address potholes or heavily distressed areas, as its polymer-modified formula needs a stable base to cure effectively. Proper surface preparation directly influences the durability and performance of both slurry seal and micro surfacing treatments on asphalt pavements.

Cost Comparison: Slurry Seal vs Micro Surfacing

Slurry seal generally costs less per square yard compared to micro surfacing, making it a more budget-friendly option for routine maintenance on asphalt pavements. Micro surfacing, though pricier, provides quicker curing times and enhanced durability, which can reduce long-term repair expenses. Project size and pavement conditions significantly influence the overall cost effectiveness of slurry seal versus micro surfacing applications.

Performance in Various Weather Conditions

Slurry seal provides excellent water resistance and performs well in moderate climates, effectively sealing minor cracks and surface damages. Micro surfacing offers superior durability and faster curing time, making it ideal for harsh weather conditions, including extreme heat and heavy rainfall. Both treatments prevent moisture intrusion, but micro surfacing's polymer-modified formula ensures long-lasting performance in freeze-thaw cycles and high-traffic areas.

Suitable Use Cases for Slurry Seal and Micro Surfacing

Slurry seal is ideal for routine maintenance on low- to moderate-traffic roads, extending pavement life by sealing small cracks and surface imperfections without significant structural repairs. Micro surfacing is better suited for high-traffic areas and roads requiring thicker overlays to address raveling, minor rutting, and enhanced skid resistance. Both methods improve pavement durability but differ in curing times and thickness, influencing their application based on traffic volume and road condition severity.

Environmental Impact and Sustainability

Slurry seal and micro surfacing differ significantly in environmental impact and sustainability, with slurry seal typically using lower amounts of polymer-modified emulsions, resulting in reduced chemical emissions and energy consumption during application. Micro surfacing, while offering longer-lasting pavement protection, involves higher energy use and emits more volatile organic compounds (VOCs) due to its rapid curing process and polymer content. Selecting slurry seal promotes eco-friendly road maintenance through lower carbon footprint and material recyclability, whereas micro surfacing emphasizes durability at a potential cost to environmental sustainability.

Choosing the Right Asphalt Treatment for Your Project

Slurry seal and micro surfacing are both effective asphalt treatments designed to extend pavement life, with slurry seal best suited for light-duty surfaces and micro surfacing ideal for high-traffic areas due to its faster curing time and greater durability. Micro surfacing incorporates polymer-modified emulsions that provide superior resistance to cracking and rutting compared to the aggregate and asphalt emulsion blend in slurry seal. Selecting the appropriate treatment depends on traffic load, existing pavement condition, and project timeline to ensure optimal performance and cost-efficiency.

Slurry Seal vs Micro Surfacing Infographic

materialdif.com

materialdif.com