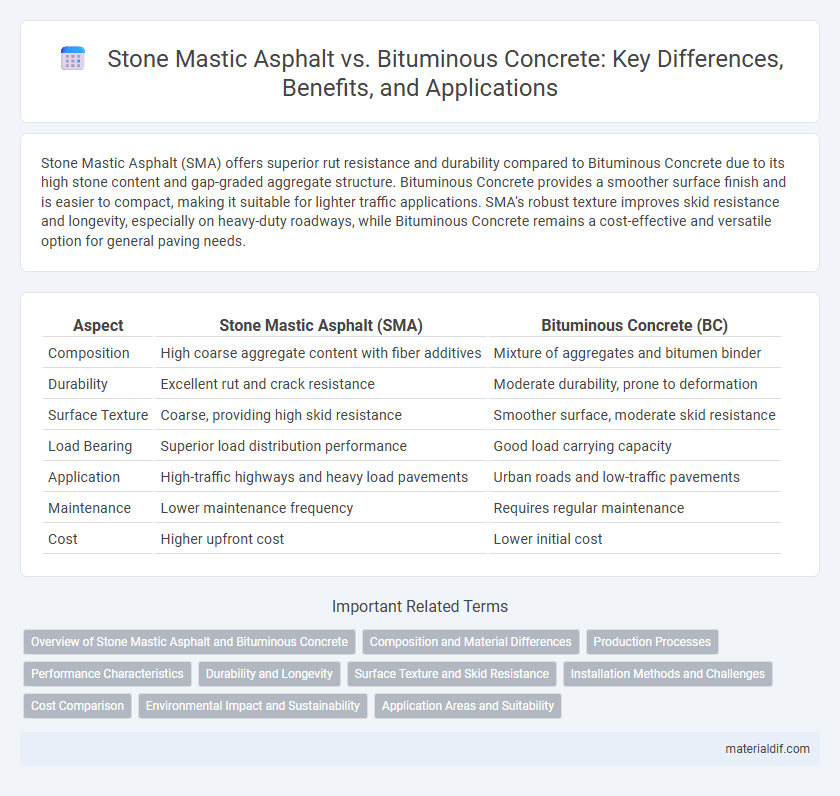

Stone Mastic Asphalt (SMA) offers superior rut resistance and durability compared to Bituminous Concrete due to its high stone content and gap-graded aggregate structure. Bituminous Concrete provides a smoother surface finish and is easier to compact, making it suitable for lighter traffic applications. SMA's robust texture improves skid resistance and longevity, especially on heavy-duty roadways, while Bituminous Concrete remains a cost-effective and versatile option for general paving needs.

Table of Comparison

| Aspect | Stone Mastic Asphalt (SMA) | Bituminous Concrete (BC) |

|---|---|---|

| Composition | High coarse aggregate content with fiber additives | Mixture of aggregates and bitumen binder |

| Durability | Excellent rut and crack resistance | Moderate durability, prone to deformation |

| Surface Texture | Coarse, providing high skid resistance | Smoother surface, moderate skid resistance |

| Load Bearing | Superior load distribution performance | Good load carrying capacity |

| Application | High-traffic highways and heavy load pavements | Urban roads and low-traffic pavements |

| Maintenance | Lower maintenance frequency | Requires regular maintenance |

| Cost | Higher upfront cost | Lower initial cost |

Overview of Stone Mastic Asphalt and Bituminous Concrete

Stone Mastic Asphalt (SMA) is a durable pavement material characterized by a high stone content and a gap-graded aggregate structure, providing excellent resistance to rutting and deformation. Bituminous Concrete, also known as hot mix asphalt, is a widely used flexible pavement composed of mineral aggregate bound with bitumen, offering smooth surface finish and good load distribution. While SMA emphasizes durability and structural performance, Bituminous Concrete is preferred for cost-effectiveness and versatility in various road construction projects.

Composition and Material Differences

Stone Mastic Asphalt (SMA) features a coarse aggregate skeleton with high natural stone content, combined with a rich mortar of bitumen, filler, and fibers to enhance durability and rut resistance. Bituminous Concrete, often called Hot Mix Asphalt (HMA), consists of a more homogenous mix of fine and coarse aggregates bound by asphalt cement, resulting in a smoother texture but less resistance to deformation under heavy loads. The key material difference is SMA's higher binder content and fiber reinforcement, which provide superior performance in high-stress road conditions compared to the more conventional composition of Bituminous Concrete.

Production Processes

Stone Mastic Asphalt (SMA) production involves combining a high percentage of crushed stone with a rich bitumen binder and fibers to enhance durability and rut resistance. Bituminous Concrete is produced by mixing aggregates with bitumen at controlled temperatures, creating a homogeneous material for flexible pavement layers. SMA's specialized mixing process requires precise temperature control to ensure proper fiber dispersion and binder coating, differentiating it from the more straightforward production of Bituminous Concrete.

Performance Characteristics

Stone Mastic Asphalt (SMA) offers superior rut resistance and durability due to its high stone content and strong binder mastic, making it ideal for high-traffic roads. Bituminous Concrete (BC), while more flexible and easier to compact, tends to deform under heavy loads and is more susceptible to cracking over time. SMA's gap-graded aggregate structure provides enhanced skid resistance and longevity compared to the typically dense-graded mixture of Bituminous Concrete.

Durability and Longevity

Stone Mastic Asphalt (SMA) offers superior durability and longevity compared to Bituminous Concrete due to its rich stone content and optimized binder content, which enhances resistance to rutting and deformation under heavy traffic loads. Its coarse aggregate skeleton provides excellent load distribution, reducing pavement fatigue and extending service life by up to 20% in high-stress environments. Bituminous Concrete, while more cost-effective initially, tends to exhibit faster wear and cracking, resulting in higher maintenance costs and shorter lifespan.

Surface Texture and Skid Resistance

Stone Mastic Asphalt (SMA) features a coarse surface texture with high stone content that enhances skid resistance by providing excellent aggregate interlock and roughness. Bituminous Concrete offers a smoother surface texture but typically provides lower skid resistance due to its finer aggregate composition and denser matrix. The superior surface texture of SMA makes it ideal for high-traffic areas requiring enhanced safety and durability.

Installation Methods and Challenges

Stone Mastic Asphalt (SMA) installation involves a thicker, gap-graded aggregate structure that requires precise temperature control between 190-220degC to ensure proper binder coating and compaction, reducing the risk of rutting and deformation. Bituminous Concrete (BC) uses a more uniform aggregate sizing and demands careful layer thickness control and compaction to avoid air voids, which can lead to premature cracking and water infiltration. Both methods face challenges such as temperature loss during transport, equipment calibration, and weather conditions, but SMA's robustness provides enhanced durability in high-traffic pavements compared to BC's susceptibility to deformation under heavy loads.

Cost Comparison

Stone Mastic Asphalt (SMA) generally incurs higher initial costs compared to Bituminous Concrete (BC) due to its specialized aggregate and binder requirements. Maintenance expenses for SMA are typically lower over time because of its enhanced rutting resistance and durability, resulting in better life-cycle cost efficiency. Bituminous Concrete offers a more budget-friendly upfront solution but may require more frequent repairs and resurfacing, increasing long-term expenditures.

Environmental Impact and Sustainability

Stone Mastic Asphalt (SMA) offers enhanced durability and longer service life compared to Bituminous Concrete, reducing the frequency of repairs and associated resource consumption. SMA's higher binder content and coarse aggregate skeleton improve resistance to rutting and deformation, leading to less frequent resurfacing and lower overall emissions. Bituminous Concrete tends to require more maintenance, generating more waste and energy use over time, whereas SMA supports sustainability goals through extended pavement longevity and reduced environmental footprint.

Application Areas and Suitability

Stone Mastic Asphalt (SMA) excels in high-traffic areas such as highways and heavy industrial zones due to its superior rutting resistance and durability. Bituminous Concrete is more suitable for urban roads, residential streets, and low to moderate traffic volumes, offering cost-effectiveness and ease of laying. SMA's coarse aggregate skeleton and rich mastic binder provide enhanced performance in extreme conditions, while Bituminous Concrete's flexibility supports a variety of pavement structures and maintenance regimes.

Stone Mastic Asphalt vs Bituminous Concrete Infographic

materialdif.com

materialdif.com